Plastic Fabrication

Tank and container construction

For plastic welding in tank and container production, thermoplastic workpieces are thermally connected to one another with heat and pressure. The quality of the welding seams and successful, efficient work is greatly affected by the choice of the machines and devices used. Extrusion welders from Leister are particularly popular worldwide in equipment and container construction because users appreciate the two decisive factors – welding consistency and process safety.

Do you need help by finding the right product? Our specialised sales team of Leister Japan will support you.

Applications

Services

Industries

Huge tanks and containers made of hard plastic for the cultivation of organisms living in fresh or salt water, such as algae, fish, mussels, crabs, e. g. shrimp, must meet high standards and be absolutely leak-proof because of possible germs, fungi and chemical influences.

The fish breeding tanks are either set up in halls or even used directly in the sea. In addition, there are circular net cages with holders made of plastic tubes, which are often anchored in the sea and in rivers for fish farming in nearshore areas, i.e. close to the coast or shore.

Hand extruders from Leister are used to produce and weld both fish farming variants from HDPE material.

Tunnel seals are utilized in strip mining or deep mining. Once the concrete casing is complete, a plastic sealing system made from HD-PE, PP, PVC or TPO is usually used to provide protection from any penetrating moisture. The individual sheets are laid perpendicular to the direction of the tunnel. Lightweight and versatile welding machines are required for "overhead welding." Leister offers several, suitable machines, such as TWINNY S, TWINNY T, COMET, and UNIDRIVE 500. Details can be welded easily with the handheld extruders, heat guns and matching accessories.

For the chemical industry, leak-proof and secure tanks and containers are preferably made of plastic. Depending on the storage system used, they have significant advantages compared to metallic materials and impress with their ease of maintenance.

Galvanic processes are usually carried out using aggressive chemicals. The containers for such baths must not only withstand the contents, but also be resistant against thermal and electrical influences.

Ventilation systems in industrial environments carry many aggressive gases. A long-term solution is only possible with the right plastic.

In contrast to many other substances and materials, thermoplastics can be repaired particularly well. If repairs are carried out professionally, even the original functionality can be fully restored. For example, plastic waste containers that show signs of wear over time are repaired with Leister extruders and are then absolutely leak-proof, making them ready for use again. Repairing plastic containers saves money, protects the environment and uses fewer natural resources such as crude oil. In addition, containers made of HDPE, for example, can be completely recycled.

Boats, rafts and floating docks are often made of polyolefins because they are buoyant, extremely robust and resistant to salt water.

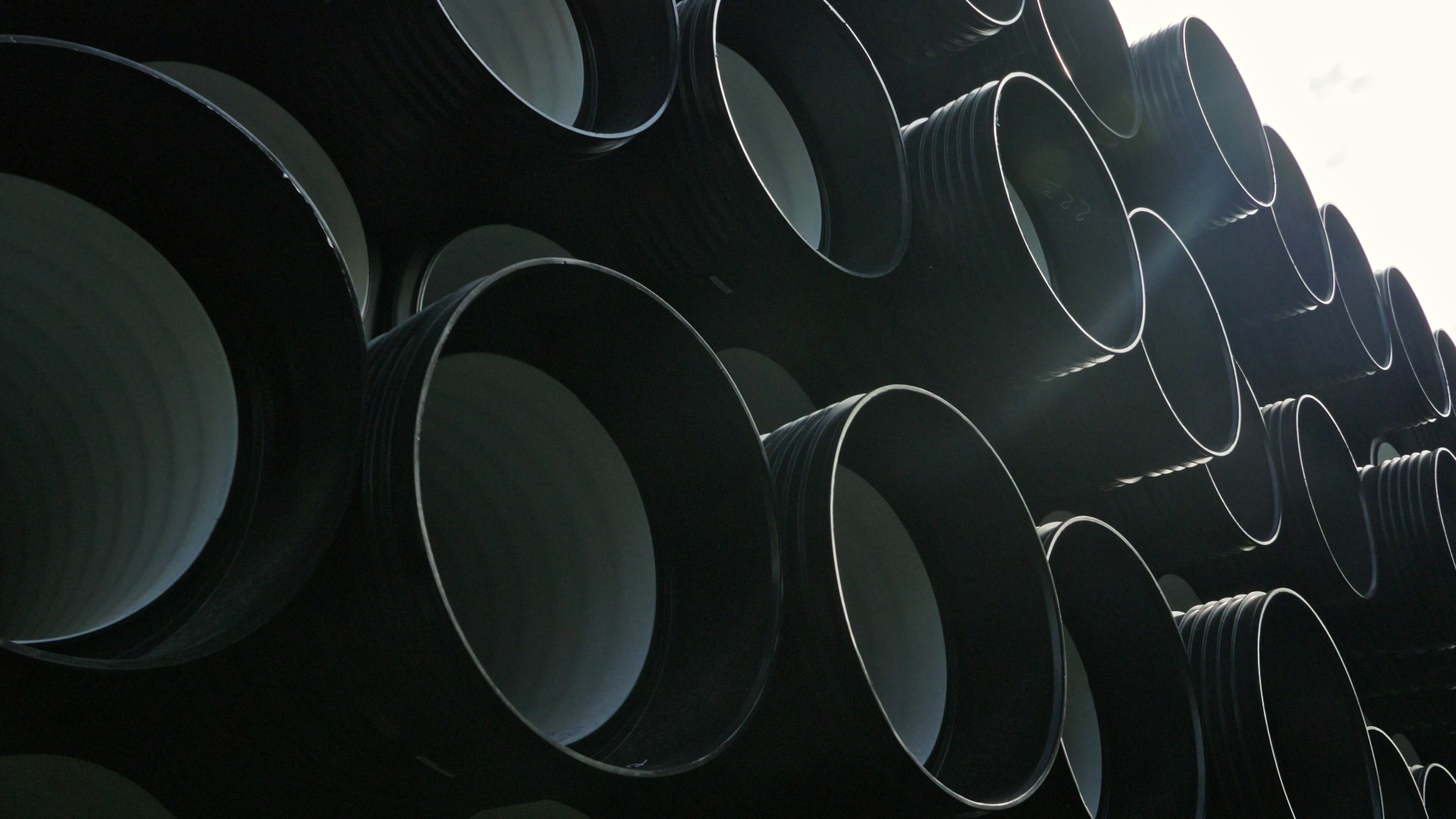

The requirements regarding hygiene and corrosion are particularly high for the infrastructure for fresh and used water. Thermoplastics are suitable for the production of tank containers and pipelines by offering sustainability and safety thanks to their suitable properties.