We are Leister

Under the Leister brand, we develop products for plastic welding and process heat applications. With our technologies like hot air and infrared, and our passion for innovation, we’re able to influence our market segment worldwide.

When tunnels or landfills are built, the quality of the welded seam is the top priority. This is because leaks would have fatal consequences for people and the environment. Geomembranes made of PE that are used for the seam must therefore be welded tight in the long term. Welding machines and hot air blowers from Leister are used for this.

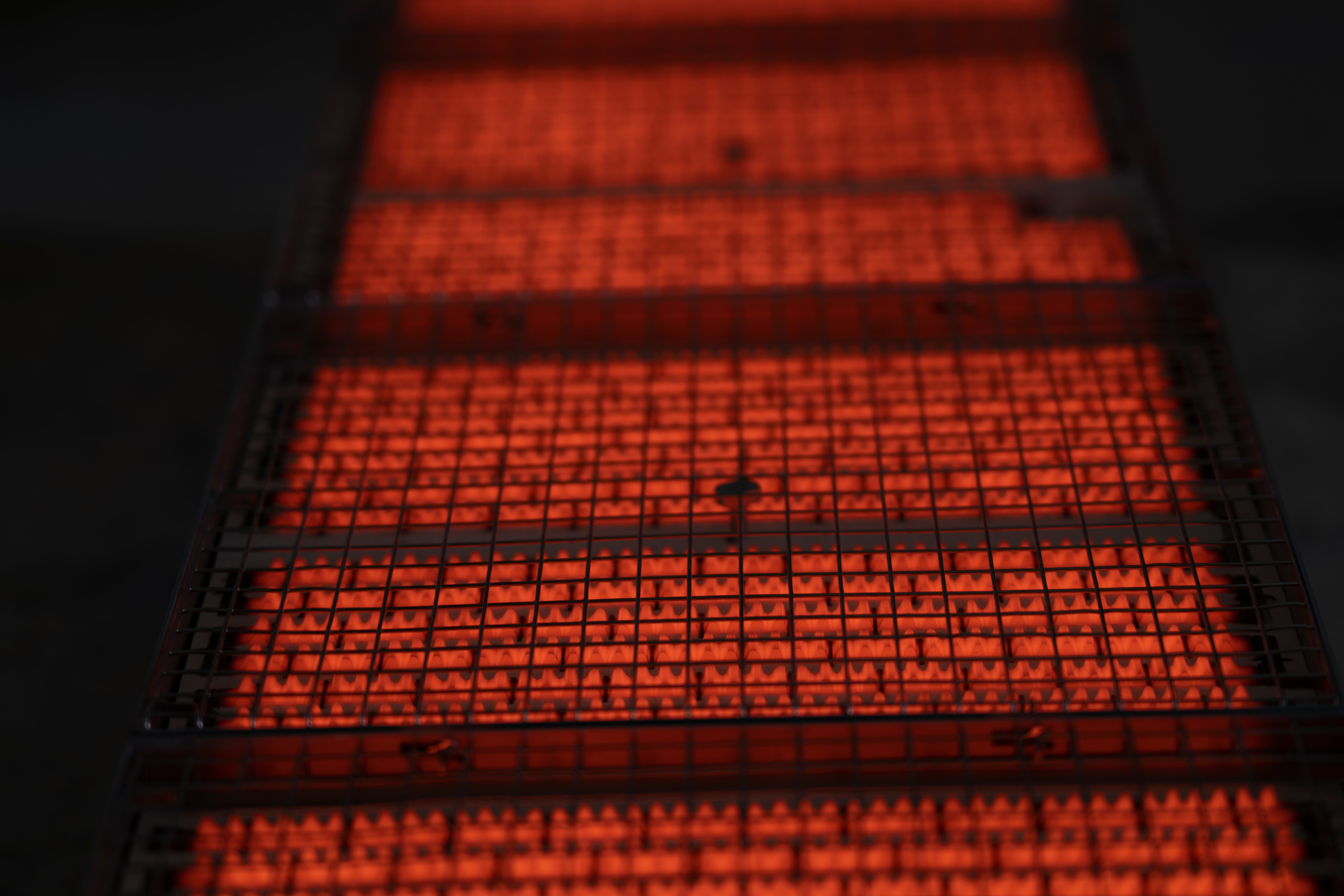

Infrared Heaters

Infrared heaters from Leister are also used in various industries where fast response times and precise temperature control are required. Typical applications are laminating, thermoforming, and riveting.

1949

- Karl Leister founds the individual enterprise "Karl Leister Elektro-Gerätebau" in Solingen, Germany.

2011

- The individual company, Leister Process Technologies, with the Leister and Axetris divisions and the national companies, is transitioned to a group structure.

- Foundation of Leister Technologies AG

2016

- smart Leister product GEOSTAR G7 LQS with digital parameter recording

2017

- Start of the digital transformation initiative with the myLeister app and other IoT products

2018

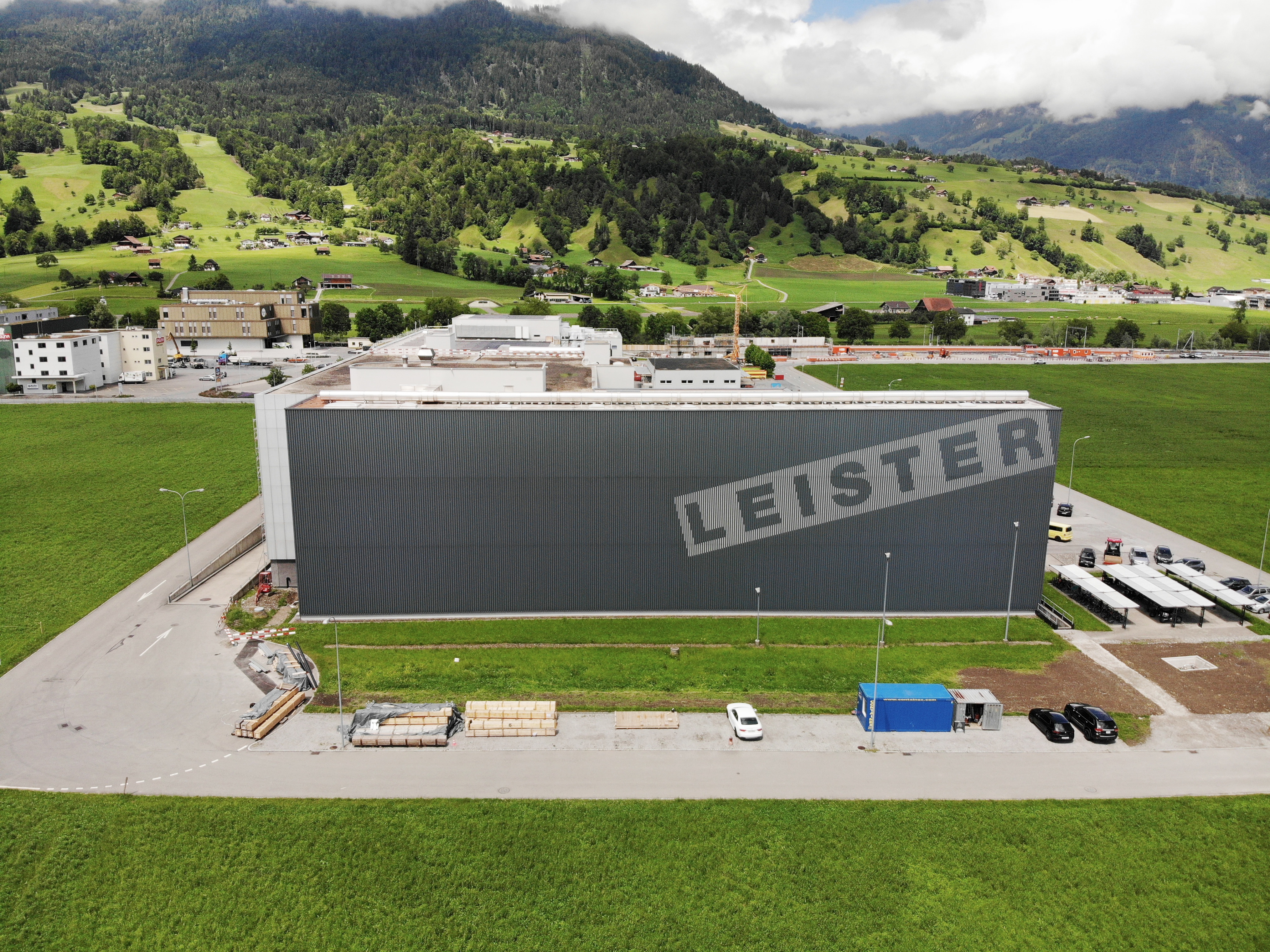

- Start of construction in Sarnen: Expansion of the company building and fully automated small parts warehouse

- Acquisition of Krelus AG to expand the Leister product portfolio with powerful infrared heaters

- Leister Academy for specialized training

2019

- Beginning of Sarnen’s building extension and consolidation of production at Leister Technologies AG in Sarnen

2020

- Launch of the myLeister web platform with new, digital customer services

2024

- Company anniversary: 75 years Leister Group

2025

- Leister hands over the laser plastic welding division to Hymson Novolas AG

Foundation

- 1949 as a sole proprietorship

Legal Form

- 2011 - a public limited company

Property

- a company of the Leister Group

Employees

- 916 worldwide, 589 of these in Switzerland

Export share

- 98%

Production

- Sarnen, Switzerland

- Shanghai, China

Distribution

- 8 national companies on 3 continents

- 130 distributors with sales and service centers in 100 countries

Product Portfolio

- Components, systems, devices, machines