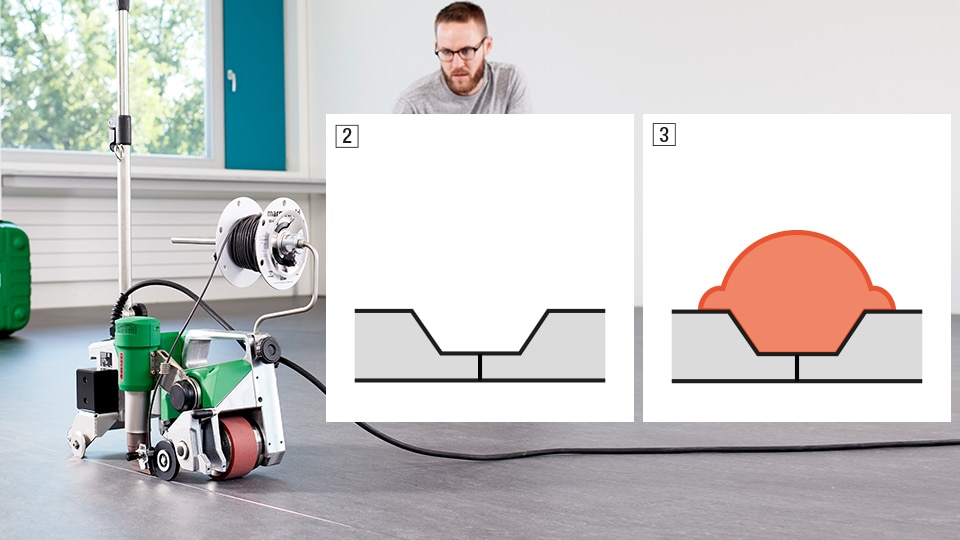

The cutting depth is determined based on the following (Fig. 1):

A welding nozzle with a narrow air outlet must be used in order to avoid any impairment to the surface covering.

Caution: An impairment only becomes visible after several cleaning cycles. Short welded seams a more easily welded with a TRIAC ST/AT or the HOT JET S than a MINIFLOOR or UNIFLOOR machine.

Manual Welding (TRIAC / HOT JET S / GHIBLI)

Recommended for short grooves, repairs, or transitions

For a consistent weld quality, the following must be taken into consideration

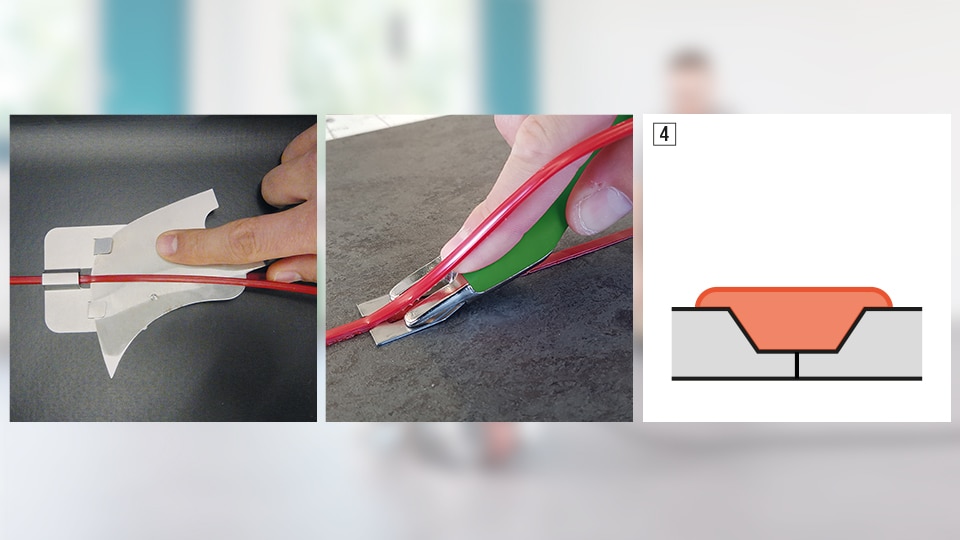

Caution: It is essential that the welding wire is cut in two stages. This prevents the weld from sagging below the level surface. (Fig. 4).

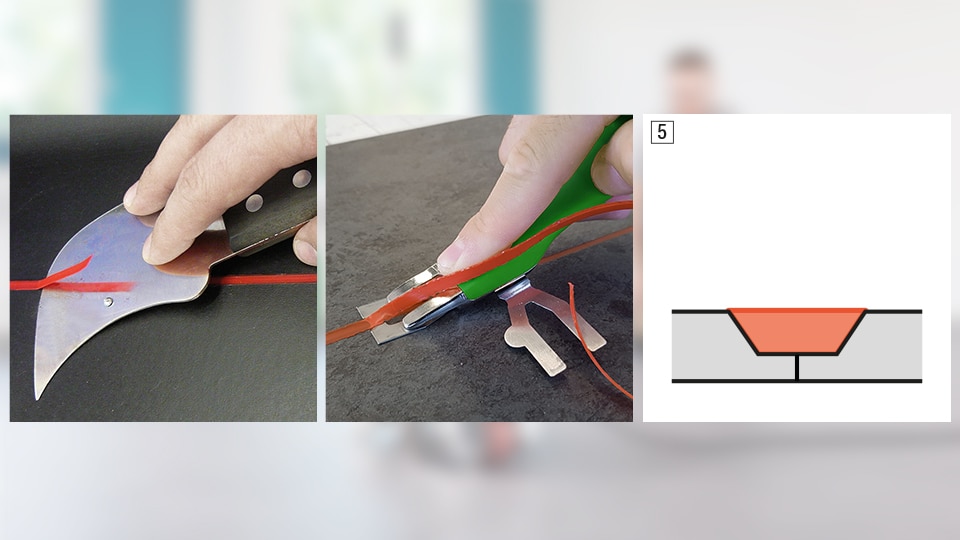

The surface is now able to bear a load and can be cleaned (Fig. 5).

The Leister Academy is your central hub for effective knowledge transfer, training and professional development. Here, we provide Leister employees, distributors and customers with practical know-how and a continuously developed training program to ensure a high level of competence and safety in the use of our Leister products.