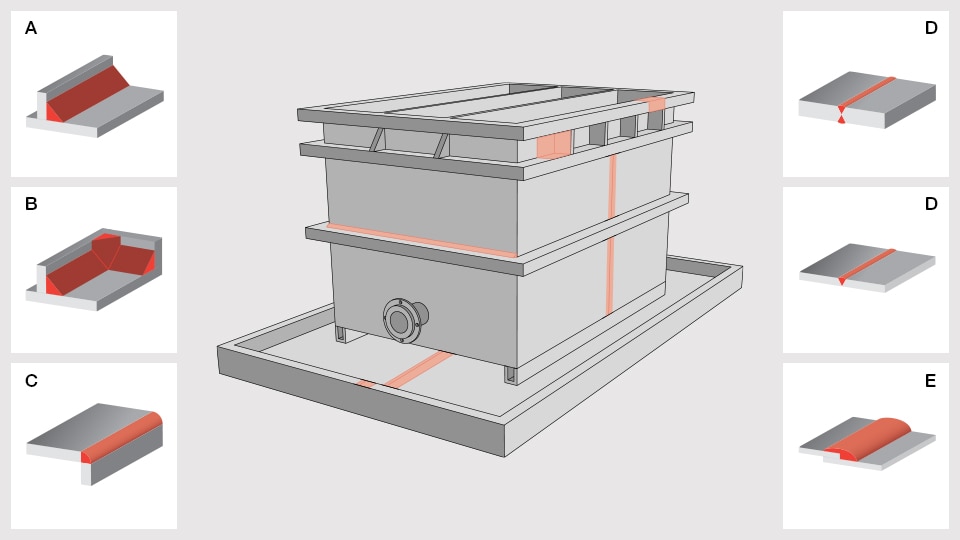

A. Fillet Weld

The fillet weld is one of the most frequently-use seam geometries. It is produced by welding two workpieces that meet in a T-joint.

B: Interior Corner Seam

Interior corner seams are generally used on difficult-to-reach locations. Free forms and spline-shaped weld seam geometries are welded most efficiently like this.

C: Corner Seam Appearance

The outer corner seam is a fillet weld in which the weld seam runs along the edge of the workpieces which are standing together. Consequently, the weld is made along the outer longitudinal side (edge).

D: X-Seam (also Double-V Seam)

The double-V seam is also known as an X-seam. It is a type of butt weld and consists of a combination of two V-seams on each of the two sides of the components to be joined.

D: V-Seam

In order to achieve the V-shaped angle that is typical for the V-seam, the workpieces are either beveled or positioned at an appropriate angle to each other.

E: Lap Seam

Lap seams are mainly used for plastic sheets. Here, the sheets are arranged on top of each other and the weld seam is laid on the upper exposed material edge.

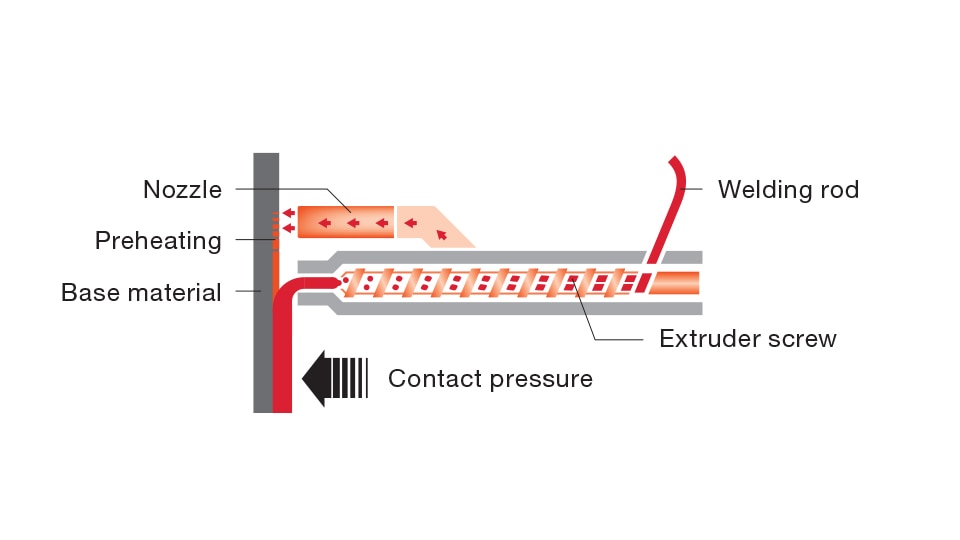

Thermal Joining of Plastics

Plastic welding requires a correspondence between the three welding parameters temperature, pressure and speed. In contrast to other joining methods, welding can achieve high resiliency and a strong, homogeneous welding seam. Plastic compounds are extremely robust and perfectly sealed when processed correctly. They can also be repaired without a loss of strength.

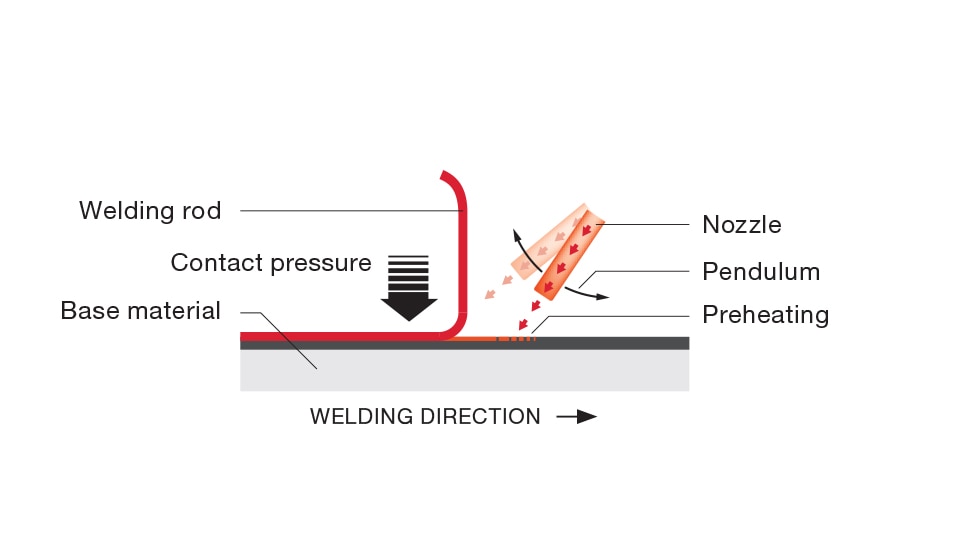

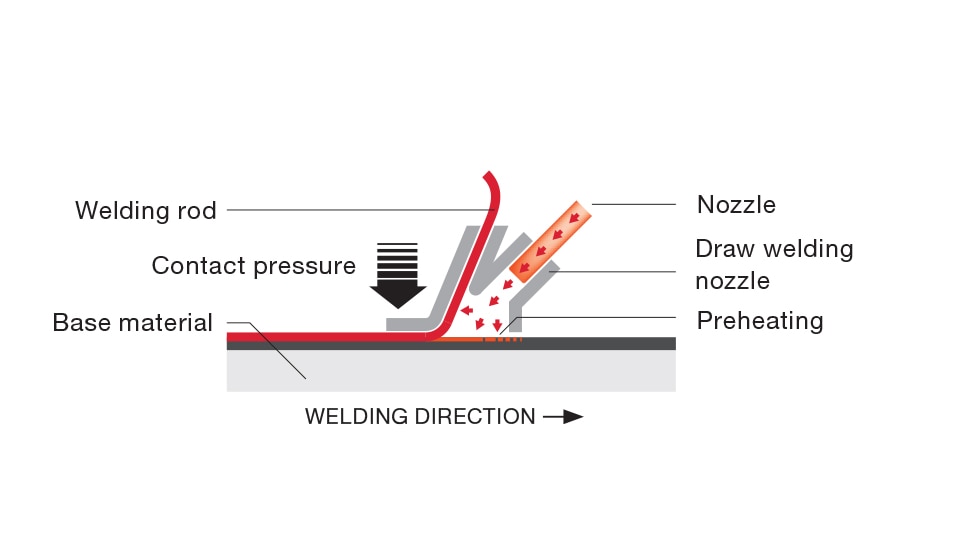

Hot Air Hand Welding

Hot Air Hand Welding is used primarily for areas that are difficult to access and for short seams. This welding process is preferred for processing amorphous plastics, in particular PVC. Particular attention must be paid to uniform pressure and constant speed when welding by hand. During the welding process, press the welding rod vertically onto the seam. The force required depends on the selected base material and the size of the welding rod

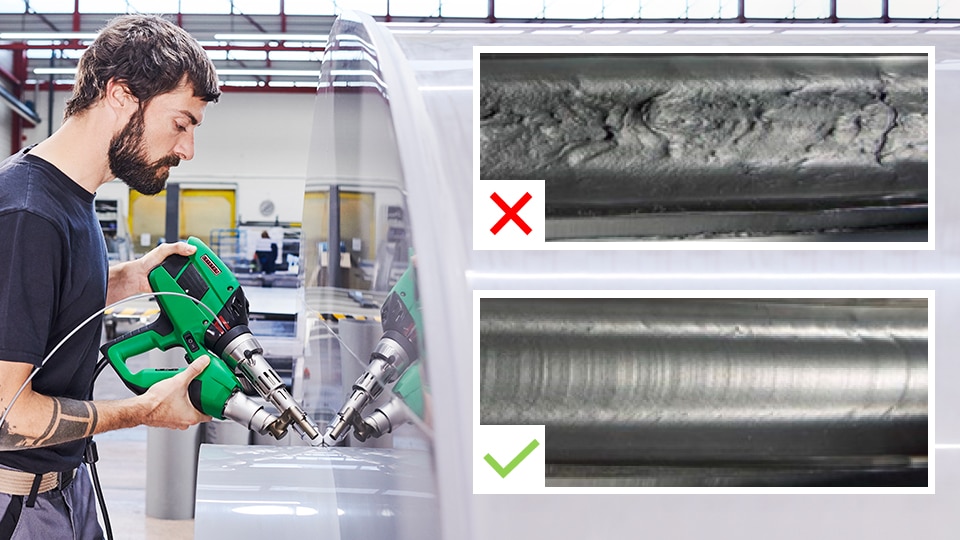

The heat escaping from the tubular nozzle should be applied alternate to the welding rod and joint in an oscillating motion in the direction of welding until the seam end is reached. When achieved correctly with the right temperature and appropriate pressure, a welding seam is formed on both sides of the weld bead in the form of a uniform double bead.