Welding considerably thicker, modified SBS and APP bitumen sheeting with the flameless BITUMAT B2 from Leister is much safer, more cost-effective and more efficient than working with an open flame.

Only one procedure is required by a single person, compared to working with an open flame, which requires two individuals.

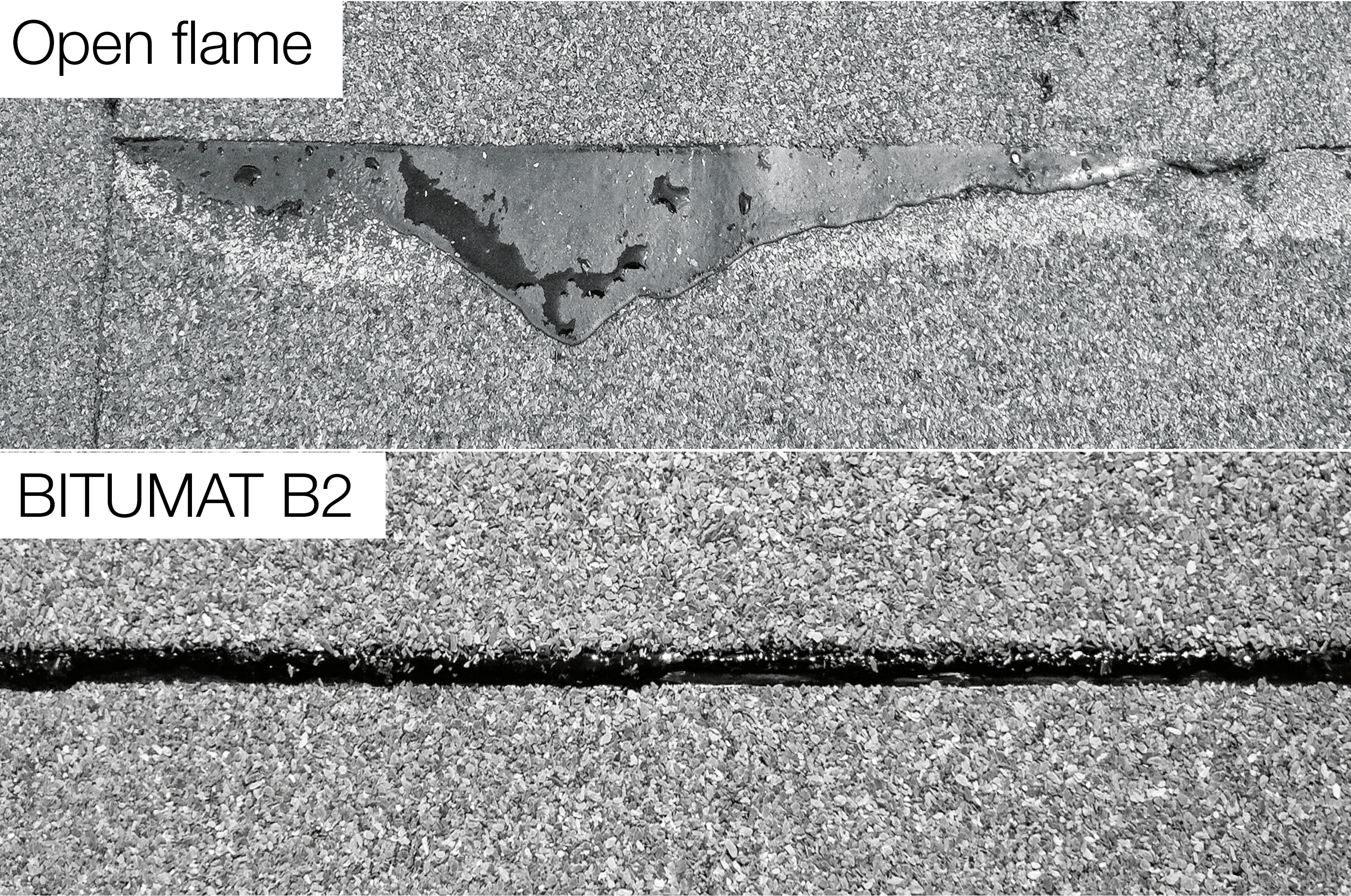

Flameless welding with hot air gives considerably better welding results than using an open flame. The welding seam is straight and considerably narrower (also see images).

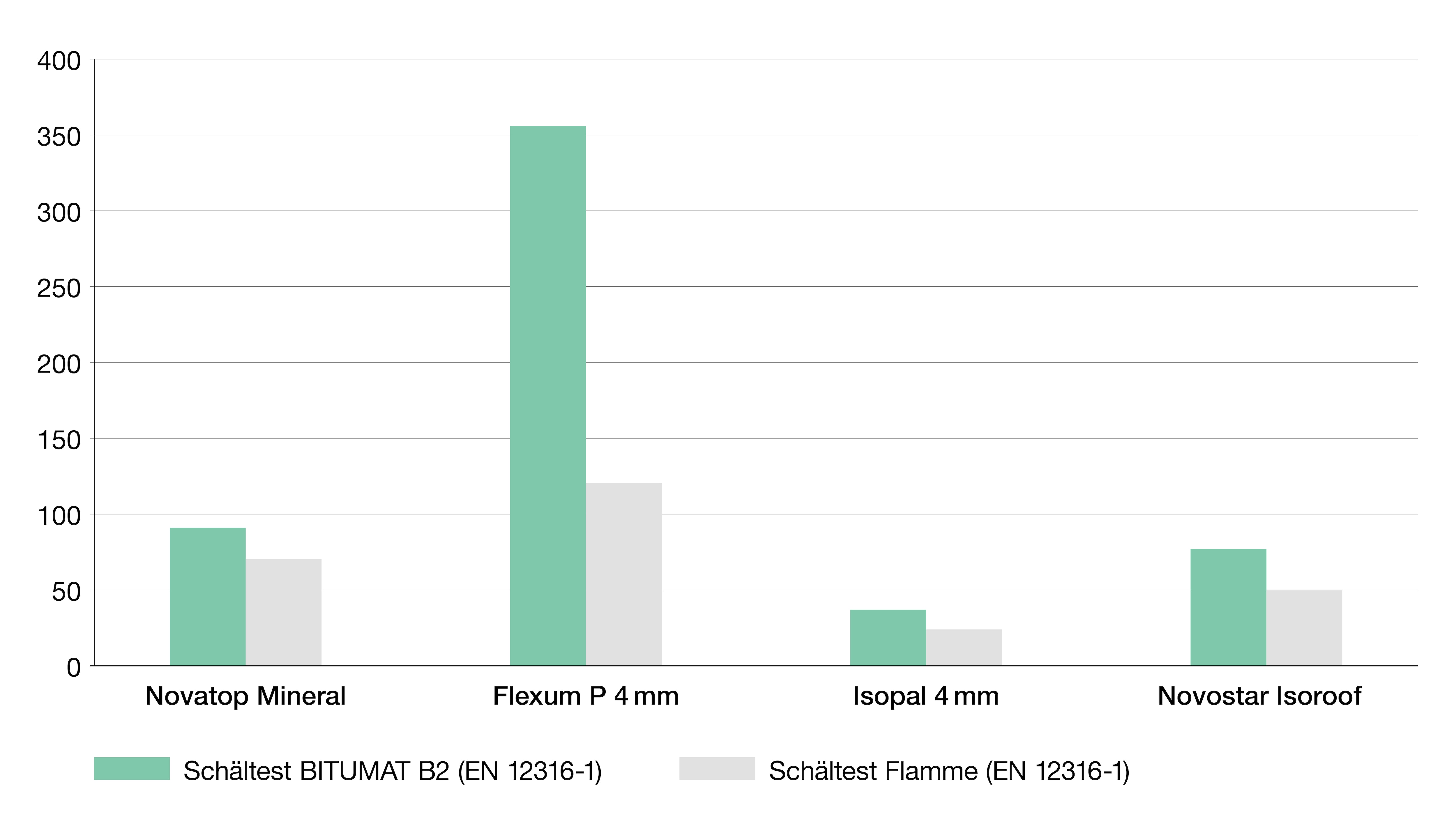

Working with the BITUMAT B2 also gives considerably better results in the peel test comparison between BITUMAT and open flame.