For virtually all coating processes, it is necessary to perform thorough cleaning and degreasing. Hot air can be used for drying out the residue of liquid cleaning agents and solvents, thus quickly and reliably preparing the surfaces for the next process step.

Hot air is also used for processes that occur downstream of the actual coating operation itself. For instance, some coating systems need to be heat-cured while varnish is both dried and cured utilizing hot air.

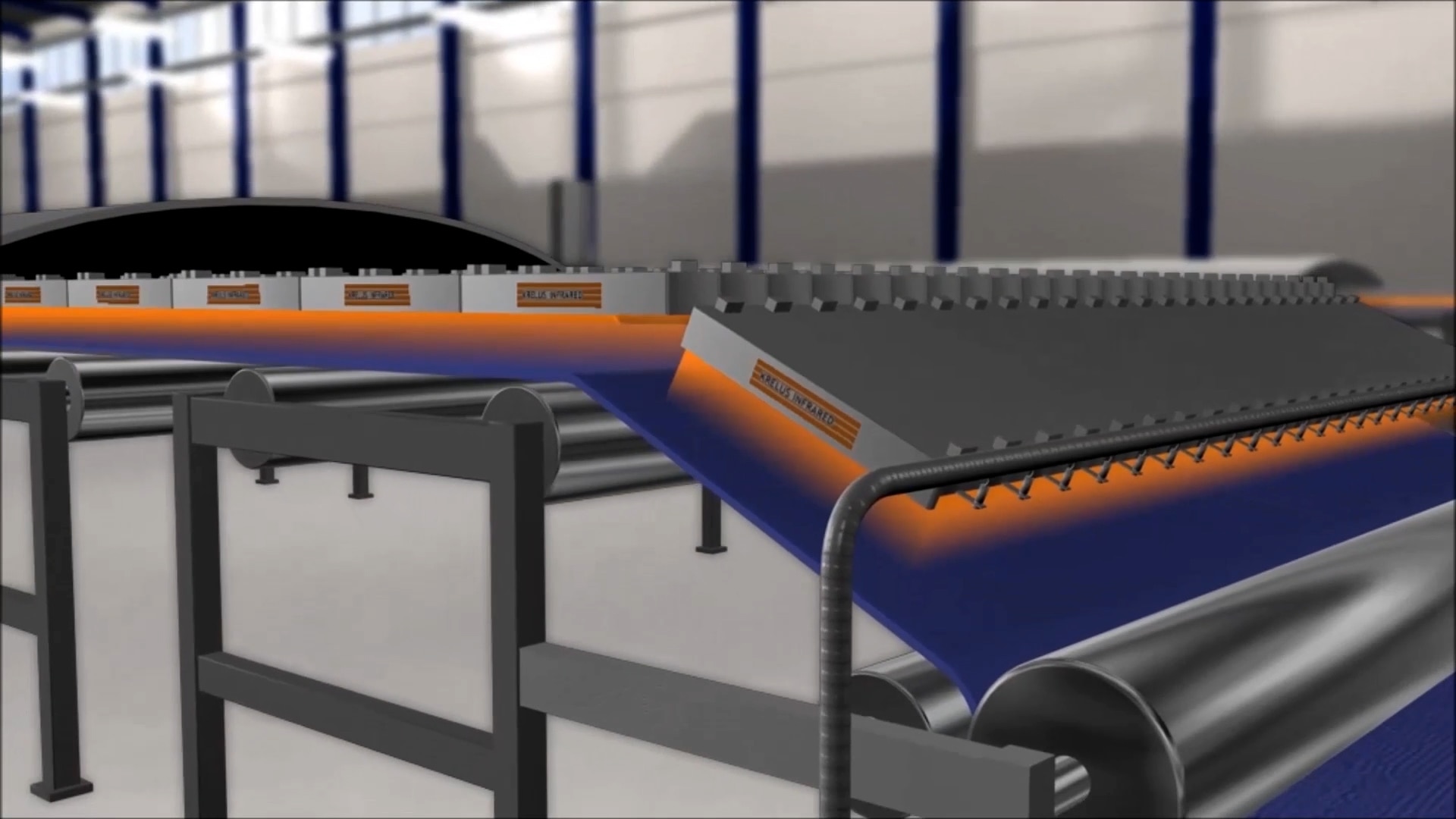

Dip coating is a standard process in the textile and paper industries. In this solvent-based process, it is necessary to dry the textile or paper. This is efficiently achieved with KRELUS infrared heaters. These heaters ensure reproducible and safe process regulation due, in large part, to their excellent controllability and short reaction times. This process step is also accomplished by utilizing IR radiation on coatings that polymerize after the dip coating process.