Infrared technology generally laminates different foams to each other or in combination with other materials. Thin decorative layers on the outside are permanently bonded to an often multi-layered core using heat-activated adhesive.

However, even PVC flooring, synthetic leather and other multi-layer decorative material can be made using infrared technology.

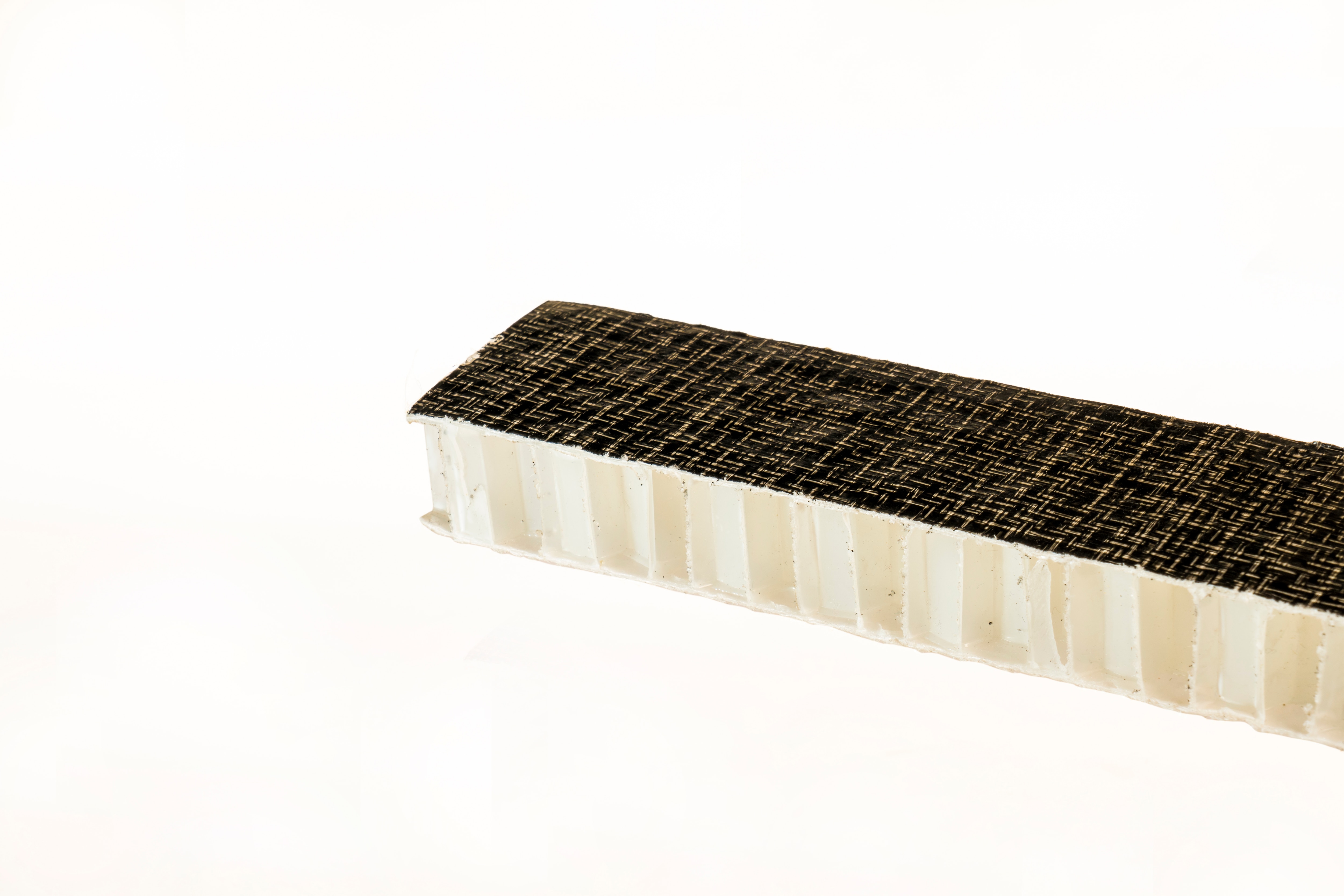

In laminating processes with hot air, the surfaces of the materials to be joined are heated evenly. For this purpose, wide-slot nozzles are often used for uniform air and temperature distribution. This process is used on foams for upholstery in the furniture and automotive industry as well as in wood processing. Here, hard, washable and scratch-resistant cover layers are laminated onto the carrier plates to increase their resistance.