Metal to Plastic Joining

Different materials such as metal and plastic can be joined and permanently connected by laser. This innovative joining process is particularly interesting in the automotive industry.

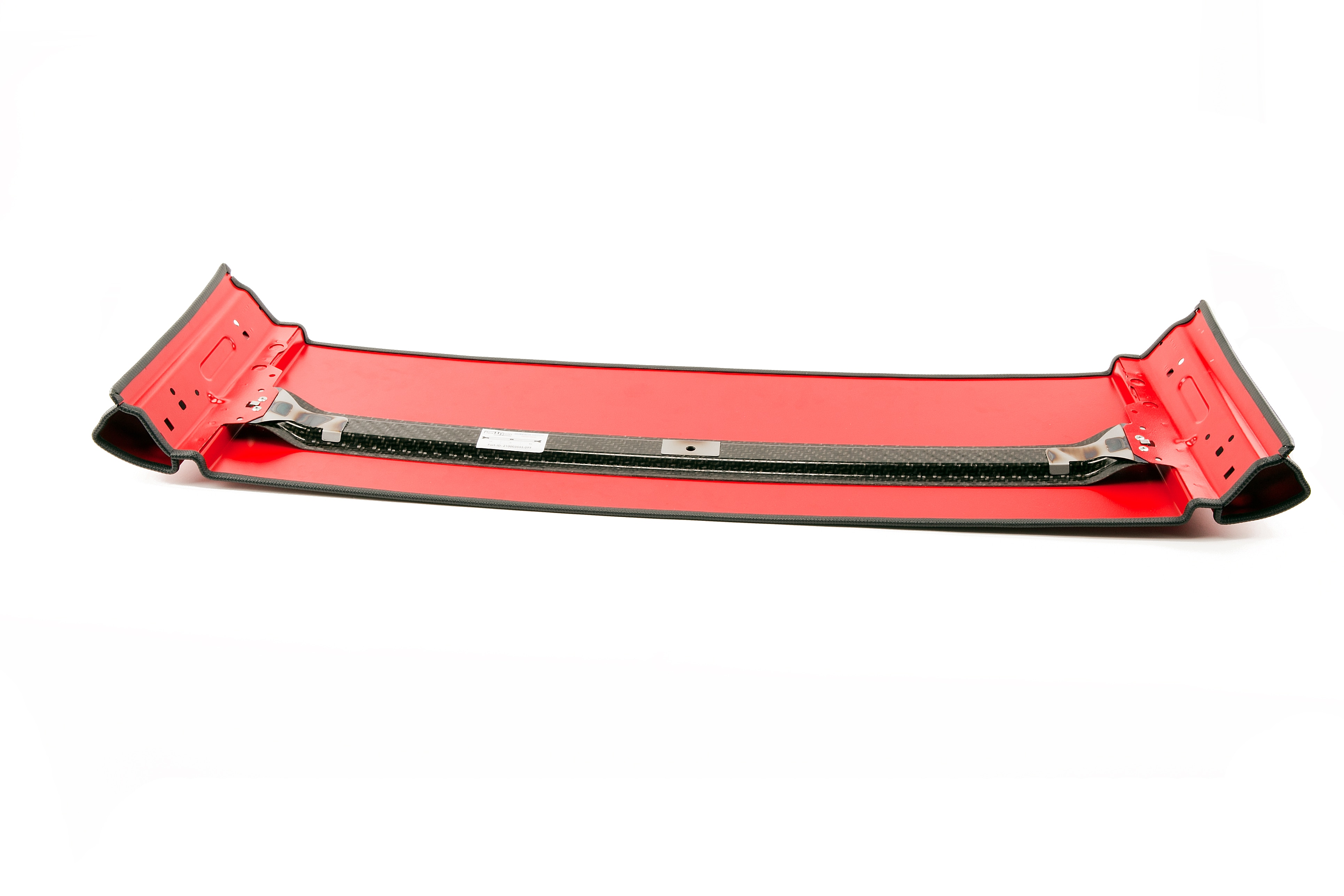

Since there has been no solution to meet the demand for weight-reduced, low-cost and extremely durable components, this project has since developed a roof reinforcement element for cars made of composite metal. In cooperation with other partners of the FlexHyJoin consortium, the CO2 emission targets of the car manufacturers can be met in the future.