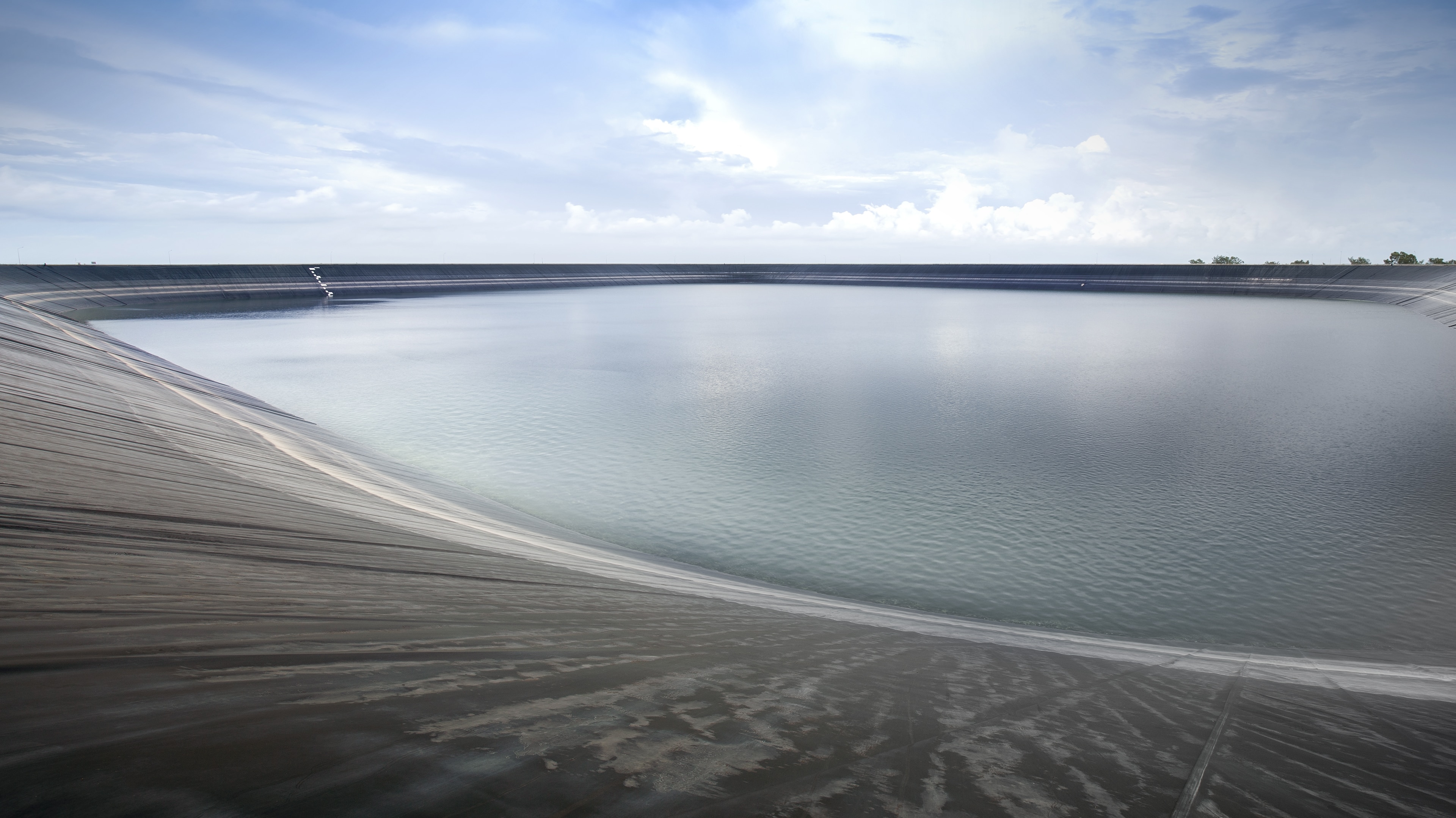

These reservoirs must be tightly welded and the liners used must have a long shelf life to prevent water seeping into the subsoil. Geomembranes are welded waterproof with Leister automatic welding machines. Testing equipment, also available from Leister, is then used to check whether the seams are tightly welded and hold.

In all these civil engineering projects, geomembranes are welded waterproof to protect against water loss into the subsoil or to protect against flooding by heavy rain. With Leister welding machines, large construction projects are no longer a challenge. The Leister testing equipment guarantees the welding seam integrity and the LQS system also documents the quality of every meter of Geomembrane welded. This is how Leister helps construction projects succeed.