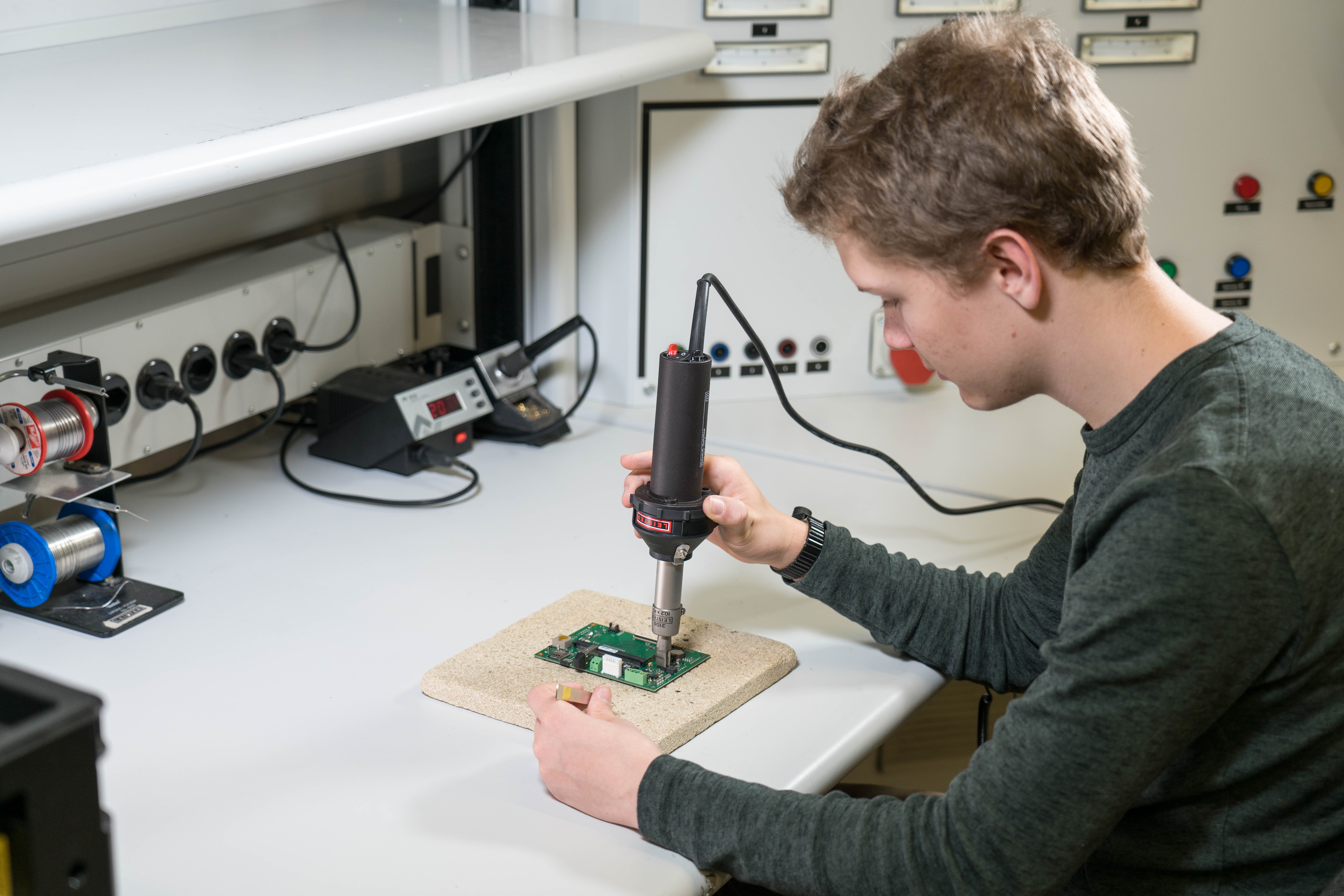

In electronics, components of Surface Mounted Devices (SMD) can be soldered with hot air directly onto a circuit board, i.e. a very flat circuit carrier. This is also known under the technical term Surface Mounted Technology (SMT). The components can of course be recycled at the end of their life cycle. The individual parts can be removed from the so-called motherboards with hot air.

Plumbing work on the roof is easily done with a hot air blower and the appropriate special nozzle. The roofing sheets are not physically changed in this process, but are connected with solder. Roof sheets, window ledges and rain gutters are soldered together and firmly connected.

With the soldering iron kit, the TRIAC AT can also be used for classic metal soldering of copper, zinc and chrome steel with solder.