Roofs made of flexible material must always be tensioned for stabilisation. The statics play a decisive role here. Structures can be made of wood, steel or reinforced concrete.

Popular roof forms made of membranes are sail surfaces, arched surfaces and high point surfaces. The fabrics used must be weatherproof to ensure a long service life. It is also important to ensure that they can withstand the snow loads and wind speeds specified in the regulations. With Leister welding machines, roof membranes are perfectly joined together so that they are tightly and permanently welded.

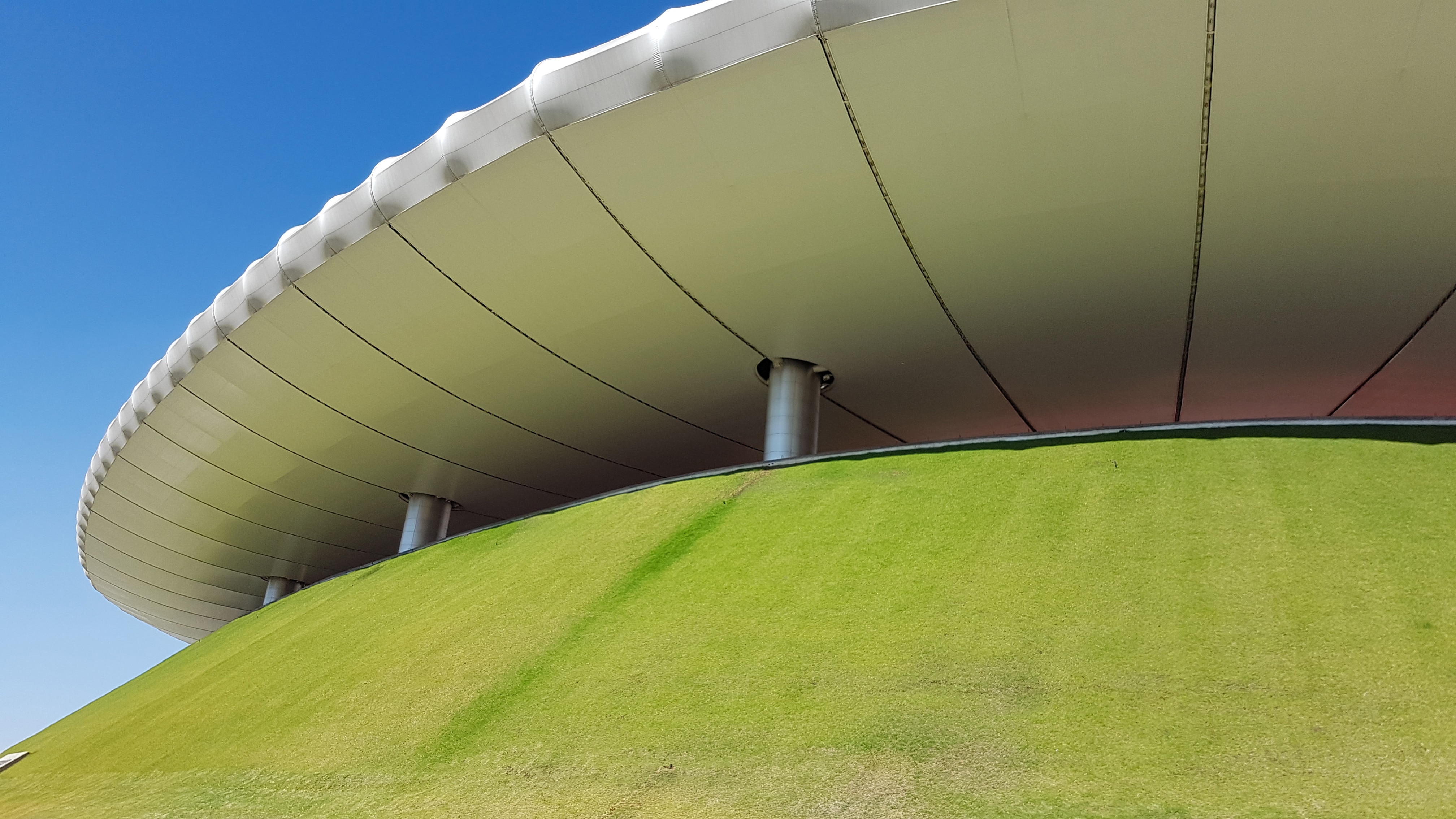

Thus roof construction projects with enormous span widths are realized. And this with a much lower construction weight than conventional roofs.

Any type of building can be covered with a textile shell, from office buildings to public buildings such as schools and gymnasiums, to event centres and warehouses.

When a building is being renovated, not only the optimisation of thermal and visual protection but also the renewal of its appearance plays a role. Textile thermoplastic membranes can be made of various natural or synthetic fibres. In order for these membranes to be durable and waterproof, they must be coated on both sides.

With Leister welding machines such as the SEAMTEK, the membranes are pre-assembled and welded. The welding equipment enables the implementation of the required design freedom.

Mobile and temporarily used membrane facades are also frequently used for advertising purposes. More information can be found under the Expertise advertising banner.