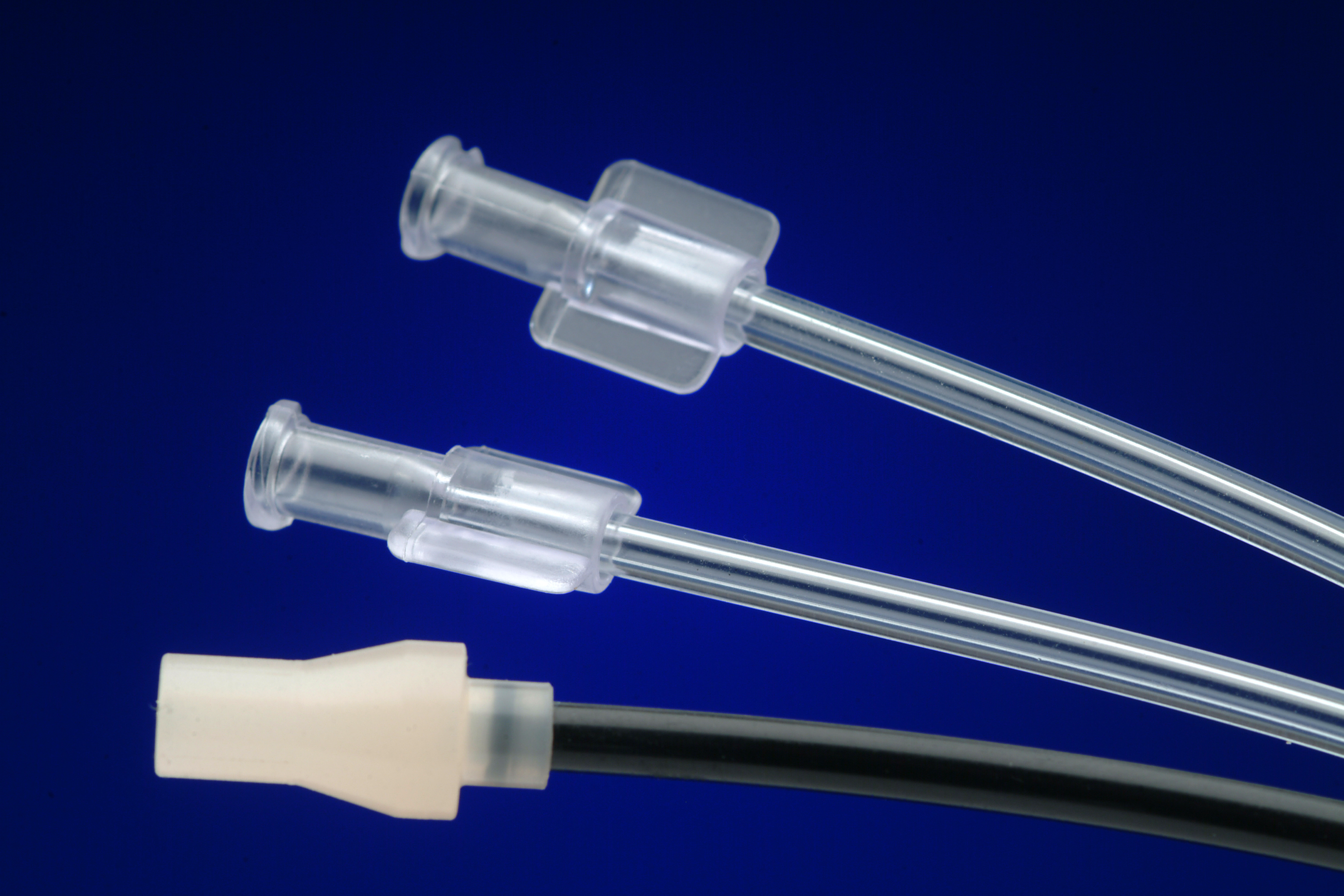

Welding Pipe and Hose Connectors

Hose connections or tube connectors can be firmly and tightly attached and sealed using laser technology.

Fittings or connectors are made of plastic and are laser welded in many cases. Since the welding requirements depend on the component, Leister uses several optics to weld rotationally symmetrical components. Depending on the customer's requirements, the customer can choose between simultaneous, quasi-simultaneous and contour processes.