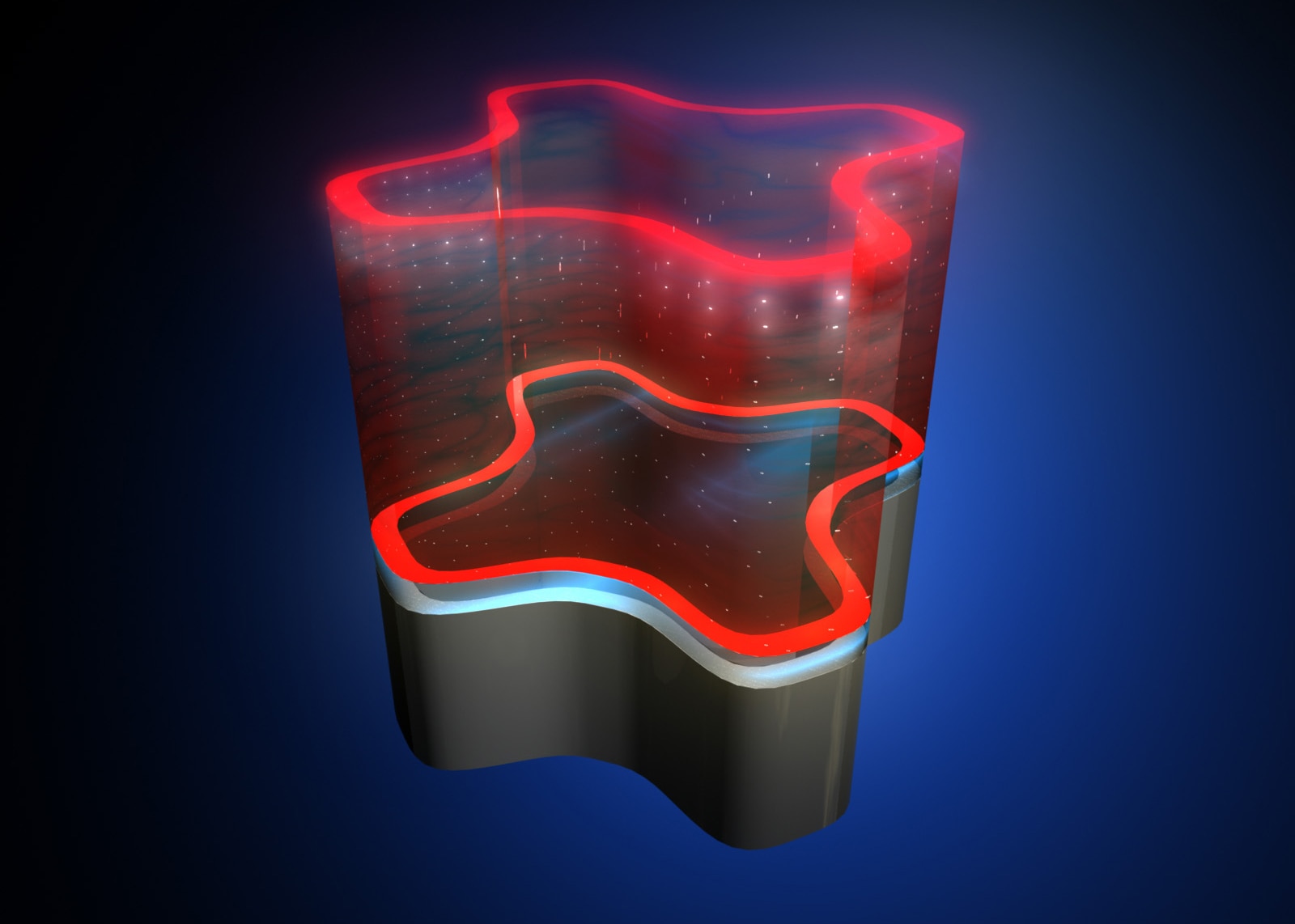

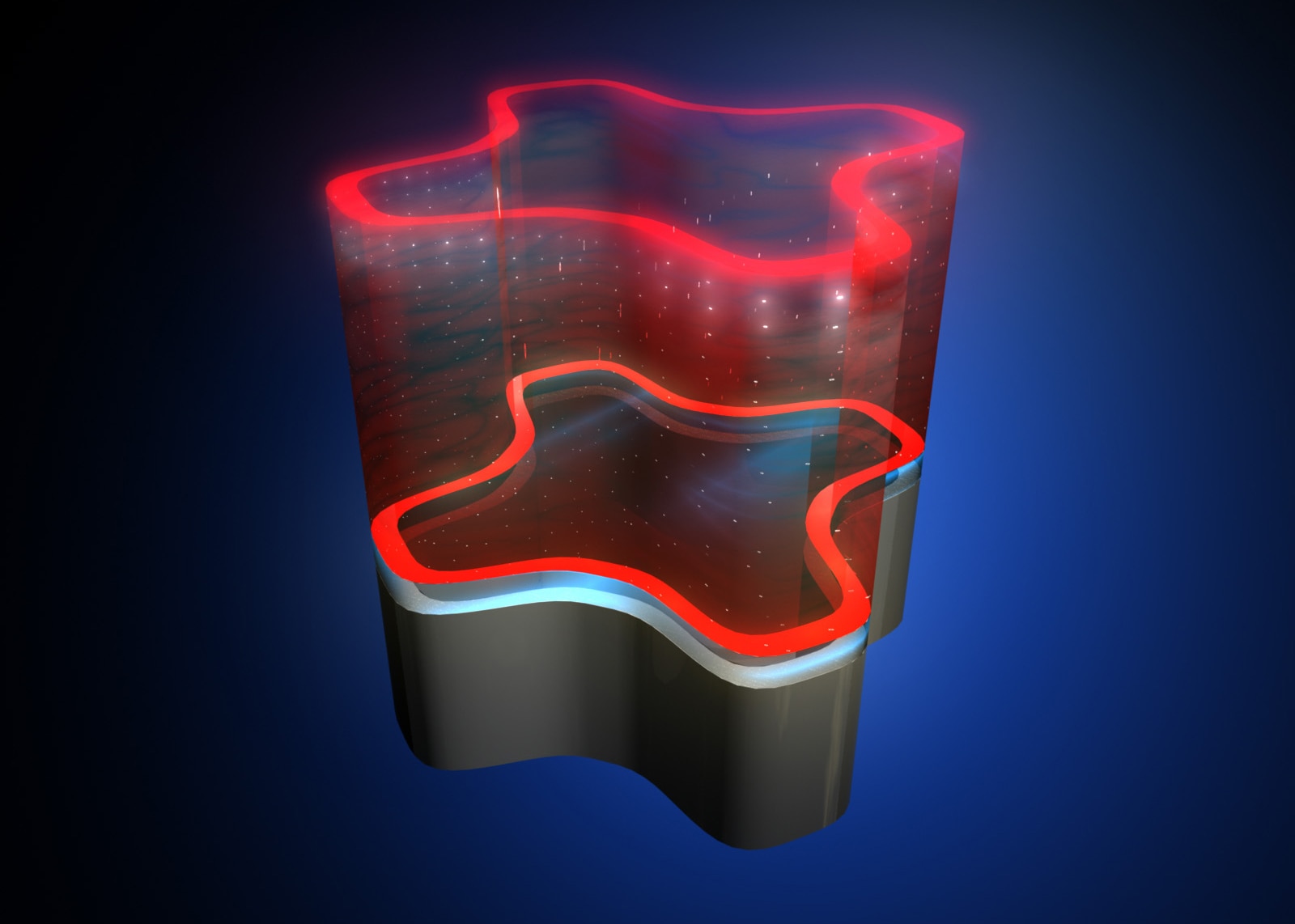

DOE is the abbreviation for "Diffractive Optical Element". A DOE is an optical component that uses a point laser beam to trace a contour. Along this contour, a DOE can be used to adapt the power density distribution to the requirements. Such optical elements are used for more complex welding geometries in simultaneous welding, as well as for optimized power density distribution in contour and quasi-simultaneous welding.

DOE are therefore adapted to the tasks and must be calculated and simulated in advance. They are designed exclusively for one wavelength. Therefore, the wavelength of the laser used should already be known for the application. Although the production of a DOE is complex, the integration into one of our optics is easy.