The Development of Plastic Welding Machines for Roofs

Leister: We know how. This statement was created because Leister experts have been developing equipment and machines in the plastic welding industry for decades. Twelve percent of Leister employees in Switzerland work in development department and strive to improve our current product offerings. Innovation, technology and quality are more than trendy buzzwords at Leister; they describe our core competencies.

1971 VARIUS

1971 Leister launched the first overlap welding machine in Switzerland.

It came with a 40 mm nozzle, temperature adjustment from 20-650°C and its welding speed along the seam varied.

1977 VARIANT

The VARIANT follows in 1977. This overlap welding machine came with the ability to freely adjust speed and temperature.

It was much more compact and weighed less than the VARIUS, which was developed six years earlier.

1988 UNIVERSAL

1988 Leister launched its next machine on the market: The UNIVERSAL. With the UNIVERSAL, both speed and temperature were freely adjustable. In addition, the air volume could be adjusted with two steps.

The UNIVERSAL was the predecessor to the UNIROOF, which became very popular with customers.

2003 VARIMAT V

With the development of the VARIMAT V in 2003, Leister achieved a real breakthrough in automatic welding machines for roofs. High sales figures proved that Leister had hit the mark with the VARIMAT V for numerous customers. A new feature of the VARIMAT V was its patented, pendular pressure roller, which welded membranes together, directly after melting. Speed and temperature were also adjustable on the VARIMAT V. In addition, it could measure the current voltage, which made it particularly valuable in areas where the electricity grid wasn't stable. This warned the welder if there wasn't enough voltage.

The VARIMAT V was the predecessor of the VARIMAT V2.

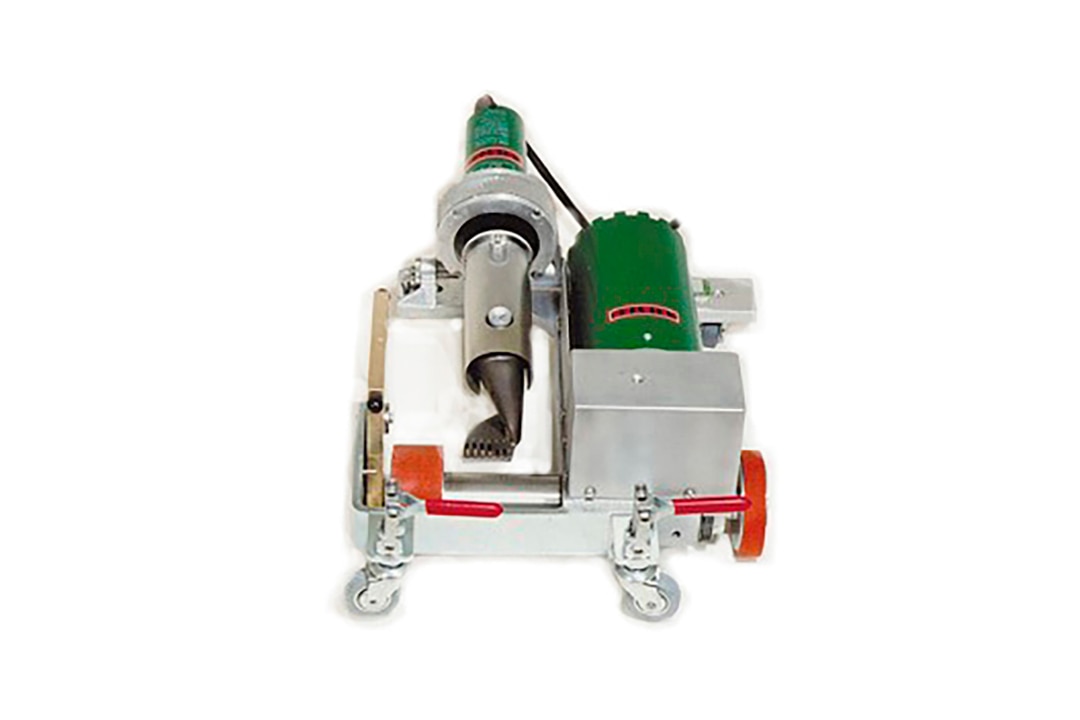

2008 UNIROOF

In 2008, a small, compact welding machine with a 30-millimeter nozzle was developed: the UNIROOF. One drawback: The ability to weld close to the edges. This is required and only possible to a limited extent with the first model of the UNIROOF.

The UNIROOF was the predecessor of the UNIROOF AT.

2009 VARIMAT V2

In 2009, the VARIMAT V2 was the first Leister welding machine with a large display and E-Drive functionality. Its welding performance was twice that of its predecessor, VARIMAT V. Due to its high productivity, the VARIMAT V2 was perfectly suited for big roofs. Its improved welding performance was achieved by the long nozzle shape and the high blower power. Also, all parameters such as temperature, speed and air output were freely adjustable. Like the VARIMAT V, the VARIMAT V2 also measured the current voltage.

A new feature that was introduced was that it automatically turned off if the voltage output was too low.

2016 UNIROOF AT

The UNIROOF AT - on the market since 2016 - became LEISTER's latest automatic welder for roofing. It has a large display and is characterized by high ergonomics. All parameters such as speed, air output and temperature are adjustable.

Welding close to the edges is possible with the UNIROOF AT. This slim and compact automatic welder is suitable for the most important applications such as basic welding, at the attic and on the attic.