High-Performance, Plastic Boats Made in Africa

The high-performance plastic boats were manufactured in South Africa with air-heated, hand extruders from Leister Switzerland.

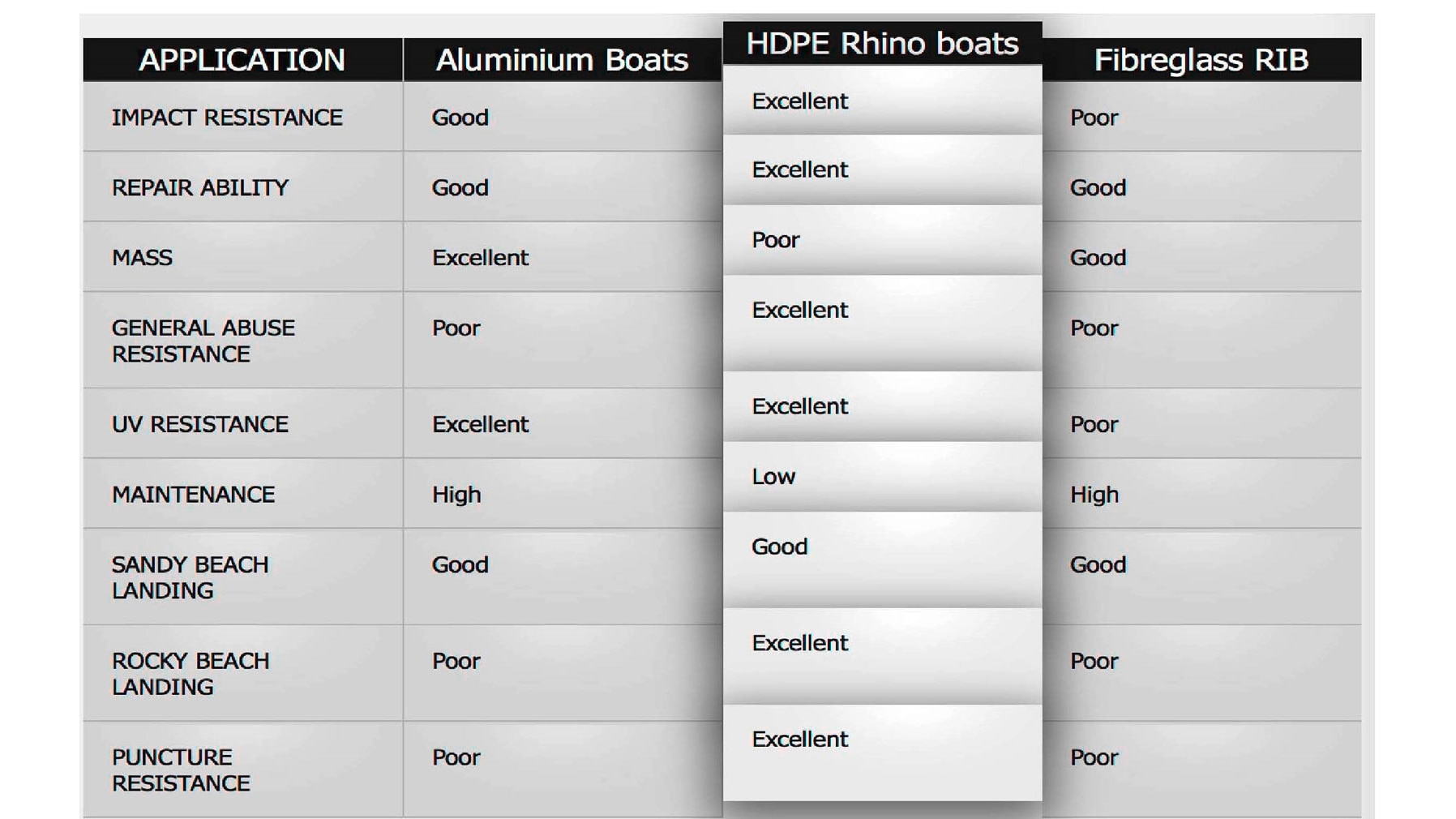

Rhino Marine (PTY) Ltd. is a shipbuilding company based in Cape Town, South Africa, that fabricates the virtually indestructible HDPE (High Density Polyethylene) offshore work boat, Rhino Craft. These vessels have been used successfully for over 15 years, primarily in the marine oil and gas fields.

Special jigs have been developed to speed up the manufacturing process. The jigs are designed to hold either the pontoon pipes or the bulkhead framework in place, while the external, underside parts like the hulls, transom and bulwarks are joined together by extrusion welding with Leister equipment.

«Rhino Marine uses the Leister FUSION 2, FUSION 3 and FUSION 3C extrusion welders, as well as the TRIAC S and TRIAC ST hot-air hand tools for their work.» Yes, you read that correctly. Although the TRIAC S is no longer in production, it is still used daily here. This is a good example of the longevity that comes with Leisters high-quality equipment.