2020 Conference on Welding of Polymeric Materials

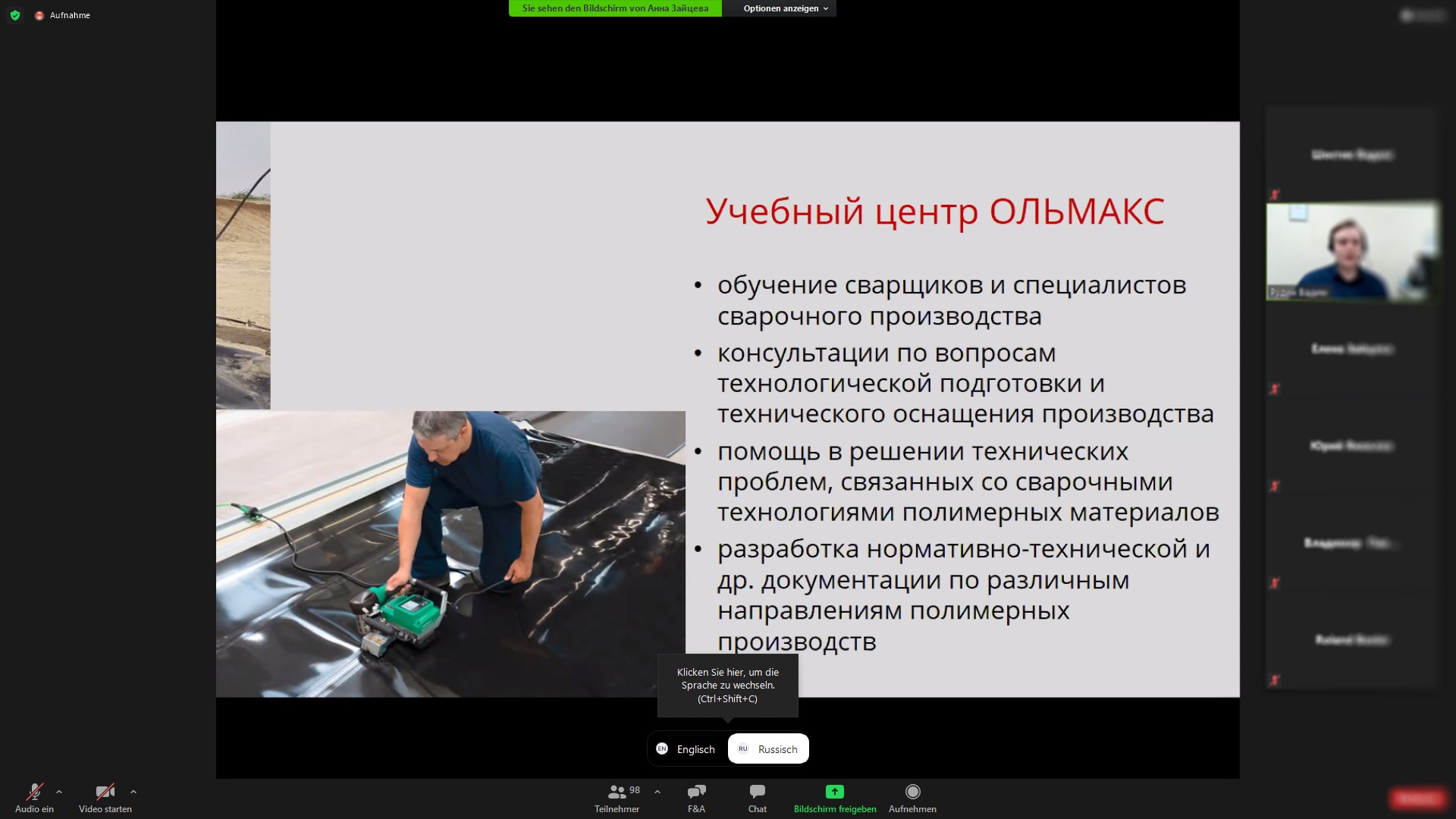

Leister representatives from Switzerland and Leister’s distributor, Olmax, from Moscow participated in the annual conference titled "The welding of polymeric materials 2020" from the Russian Association of Welders of Polymeric Materials (ASPM) on November 18-19, 2020. Even though the conference had to be held online this time due to the Coronavirus, it was a great success.

In addition, Vadim translated during Roland's lecture since many visitors did not speak the same language as Roland. Vadim had even translated the PowerPoint presentation into Russian and Cyrillic beforehand, which proved very helpful at the conference. All participants appreciated Vadim’s efforts to translate information and questions back and forth between Roland and the participants.

Since 2015, the LQS on Leister’s GEOSTAR G5/G7 and TWINNY T5/T7 automatic welding machines has proven itself in civil engineering with its quality documentation during geomembrane installations. When welding geomembranes in landfills and mines, the quality, i.e. the long-term tightness and durability of the weld seams, has the highest priority, since there can’t be any kind of pollutants that enter the groundwater.