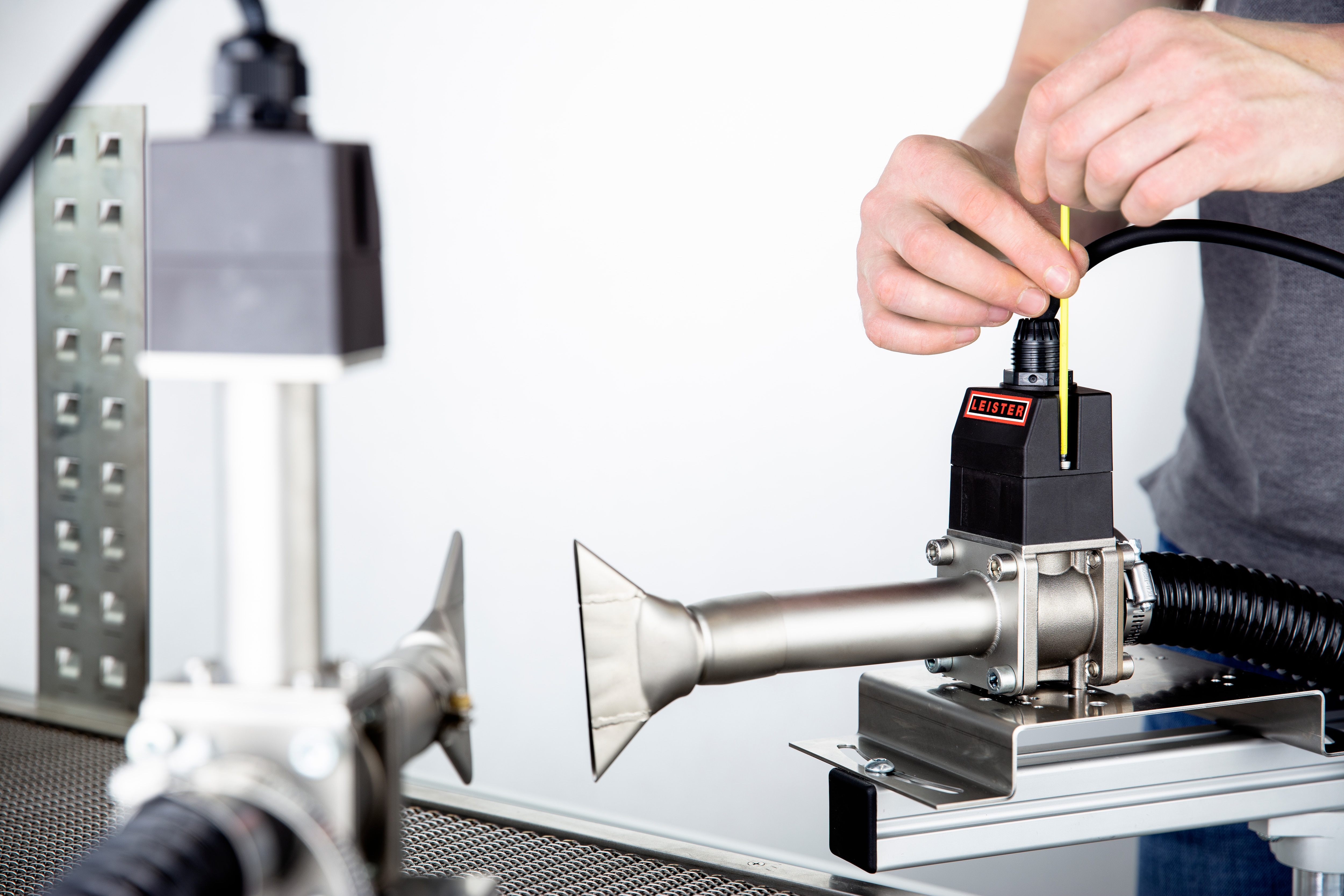

New Leister LHS 210/410 Air Heaters

Leister’s new LHS 210 and LHS 410 air heaters have been on the market since April 2021. They can be installed in all kinds of industrial plants and piping systems, thanks to their compact design and particularly easy integration. What else can they do? Find out in this blog post.

For example, the air flow can be extended with a wide slot nozzle or distributed over a larger area. Various shrinking applications within the packaging industry are possible with a screen reflector nozzle.

The LHS 410 SF air heaters differ from the LHS 210 SF due to their higher air volume, which they achieve due to their larger diameter. The LHS 410 has a tube diameter of 50 mm (2 in.) compared to 36.5 mm (1.44 in.) on the LHS 210.

In addition, the housing connection on the air heaters is located outside the air flow, which has two advantages: The air flows through the air heaters unhindered with hardly any loss in pressure. Additionally, the housing connection is protected against overheating, allowing air inlet temperatures up to 350°C/662 °F.