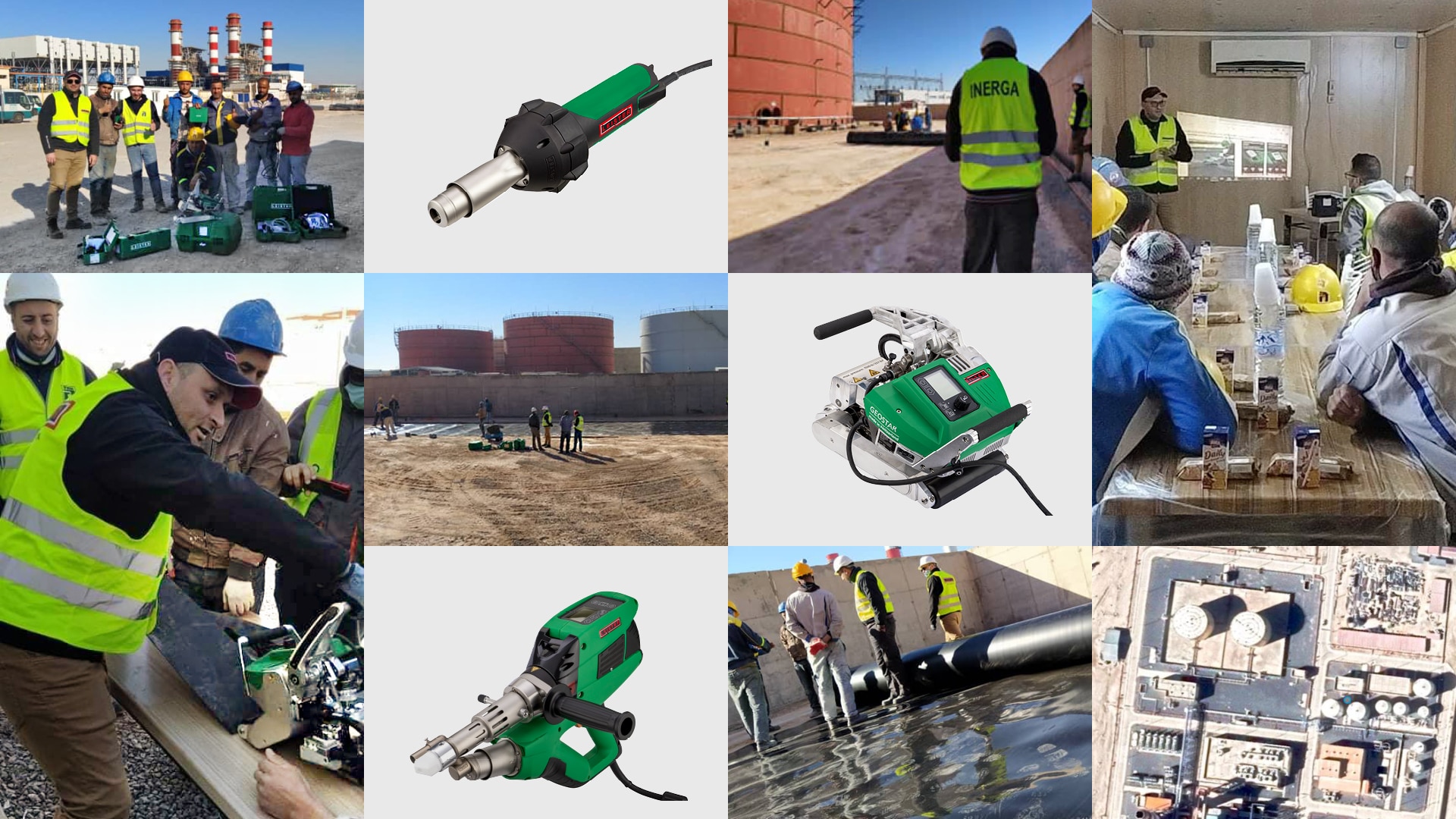

Success in Algeria – Inerga Completes Large-Scale Geo Project

Success Stories27 Aug 2021

The Algerian company Inerga is now independently completing large geo projects thanks to the excellent cooperation with Leister's Algerian distributor, ChimiBat. Read more in this blog post.

As seen in the picture, Leister's WELDPLAST S1 was used to weld the thicker HDPE geomembranes around the posts next to the oil tanks. The posts now serve as supports for the oil pipes (see marking on the right side of the picture).