Biogas Fermenter in Vietnam Welded with TWINNY

In rural Vietnam and many other areas of Asia, people still cook with fossil fuels, such as bottled gas. Read this article to find out how Leister is supporting an international research team in its search for a more environmentally friendly alternative.

The Mekong Delta in southern Vietnam is a vast maze of rivers, swamps, and islands with floating markets, Khmer pagodas, and villages surrounded by rice fields. This area offers the ideal starting position for the production of biogas. Why? Read on.

The TWINNY automatic plastic welding machine was designed by Leister for civil engineering, pool construction, mine construction, and film welding in landfill construction and is versatile in use. Due to its intuitive user guidance, even inexperienced users can quickly start working with the TWINNY professionally.

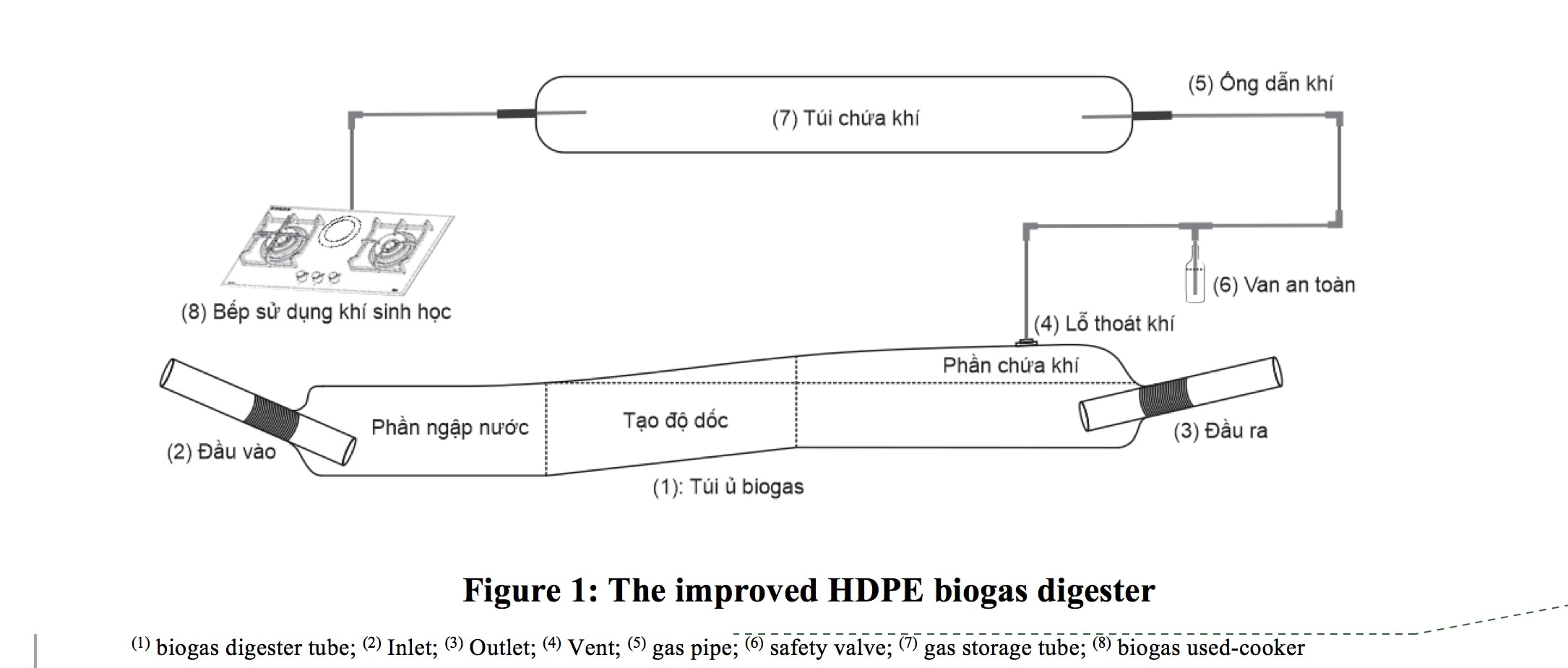

The picture shows a newly developed biogas fermenter in operation on a Vietnamese farm in the Mekong Delta.

A Vietnamese farmer connects his gas stove to the pipe (gray plastic tube) of his own biogas plant.