Chocolate and candies can also be refined with hot air and the processed air can be cleaned with catalysts. Good controllability and precise temperature control of the Leister air heaters ensure safe process control for optimum protection and the quality of the processed food.

Ceramic Leister air heaters for high air temperature

Compared to other technologies, Leister's ceramic air heaters (e.g., the LHS 210 DF, LHS 410 DF, LHS 210 DF-R, LHS 410 DF-R double flange air heaters) generate high air temperature (up to max. 1050°C) that is important for hot air processes. In addition, the ceramic Leister heating elements deliver sharp temperature changes just as quickly as the gas. Of great advantage is that the hot air flow can be controlled highly precisely with Leister blowers and PID controllers because the air flows through the air heater and not past it. With gas, the air is usually drawn past the gas burner at an uncontrolled temperature, making the process very difficult to control. And because no gas is burned during electric heat generation, fewer emissions are produced, positively affecting the CO2 balance. The latter is under the condition that green and fossil-free generated electricity is used to power the electric hot air systems.

Hot air recycling saves up to 40 percent of energy

Another important aspect is thermal energy recovery or "energy recycling". The efficiency of processes with electrically generated heat is significantly increased by capturing the air heated in the process and feeding it back into the hot air system in a precisely controlled cycle. This is not readily possible with gas. The energy savings from hot air recycling are up to 40 percent. Hot air recycling also has a very positive effect on the environment and the investment for the Leister hot air systems pays for itself in a short time.

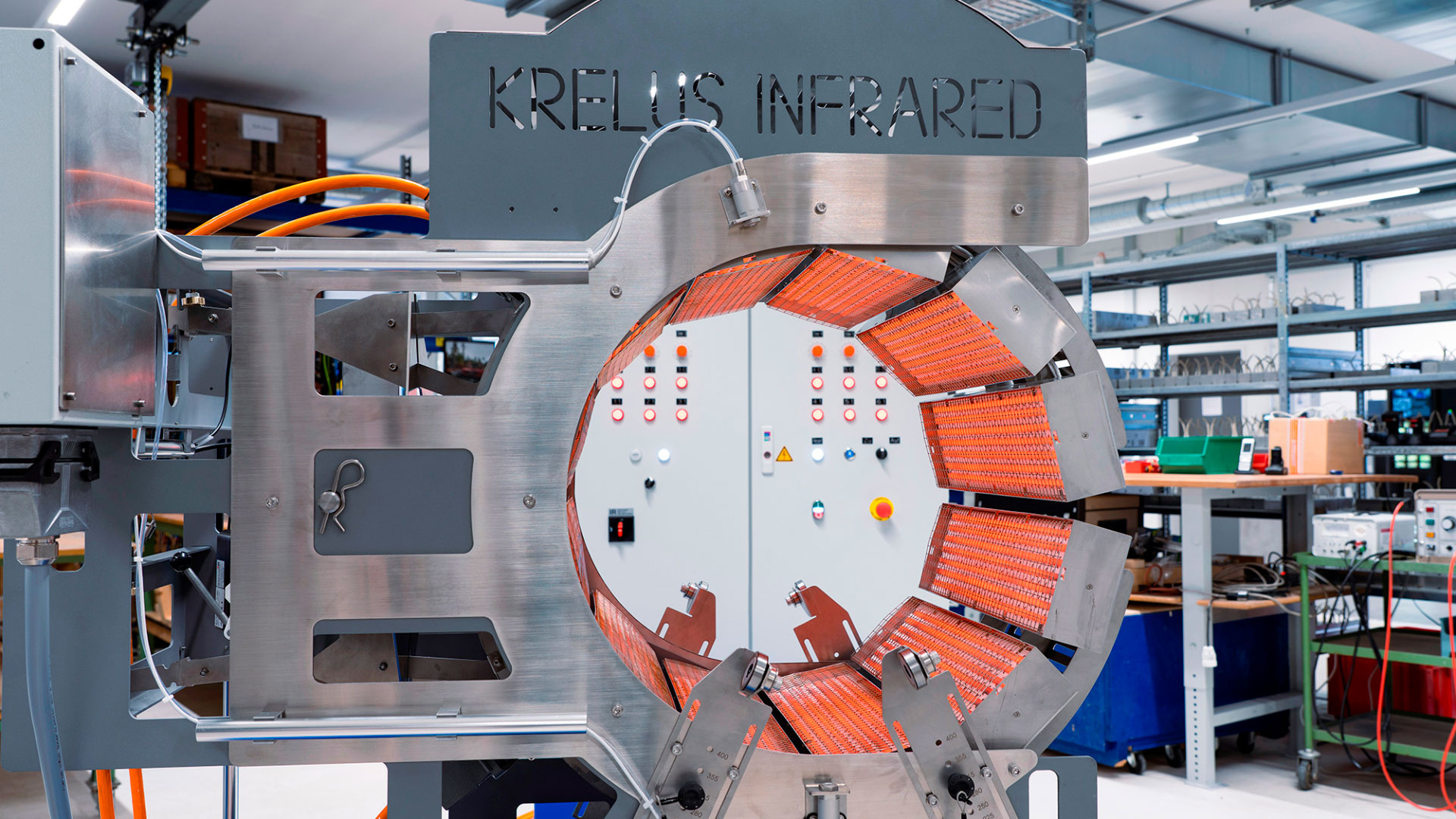

Infrared systems from Leister - another alternative