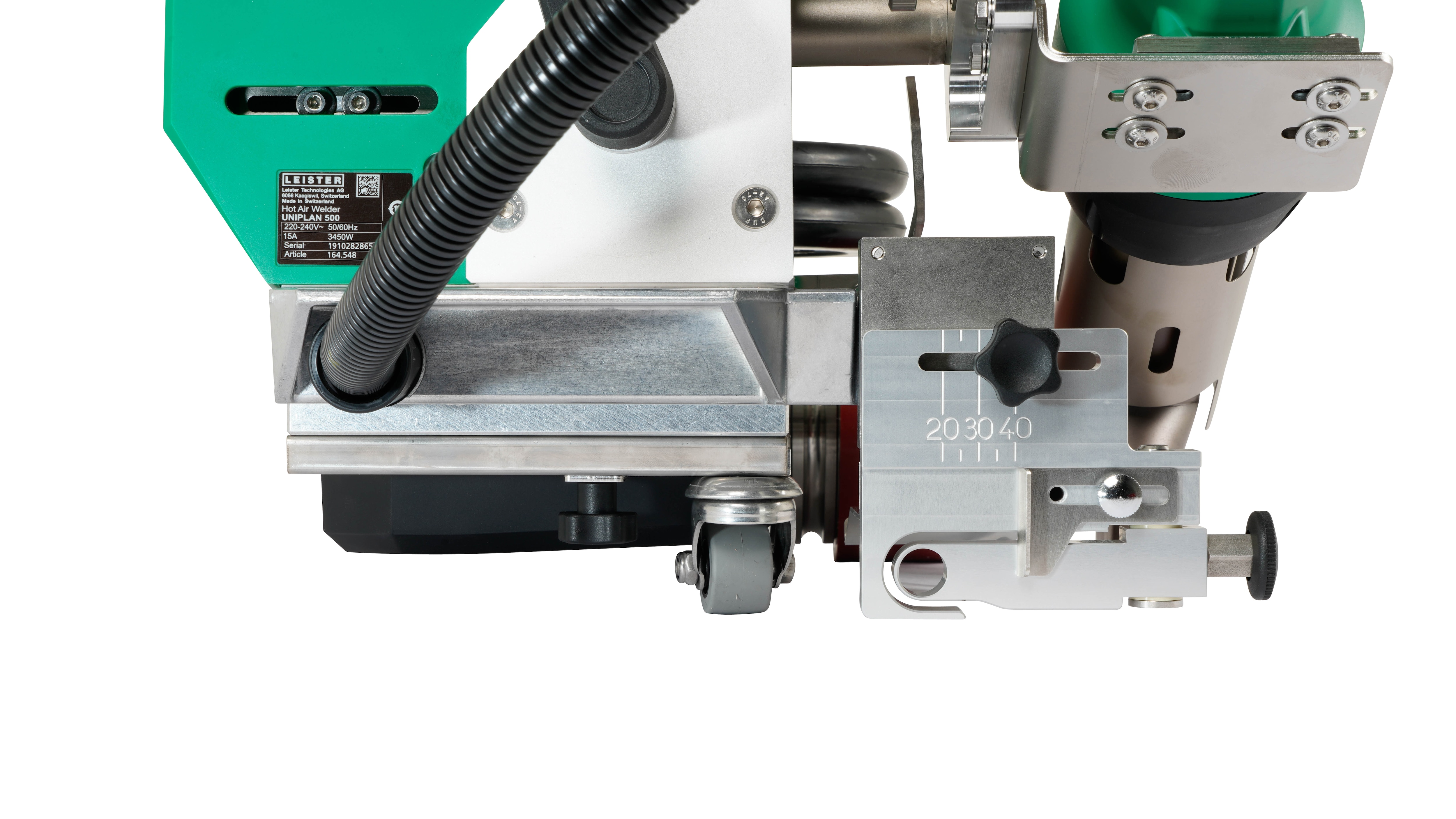

The welders are equipped with a device which lifts up the material to be welded, so there is no need for you to fold the tarpaulins prior to welding. The subsequent swiveling-in of the nozzle is semi-automatic for additional convenience for the user and process safety. The nozzle is lowered and retracted in a single, controlled movement. Through these job aids, experienced users and novices alike work effortlessly and safely with the UNIPLAN 500, because this significantly minimizes the risk of burns.

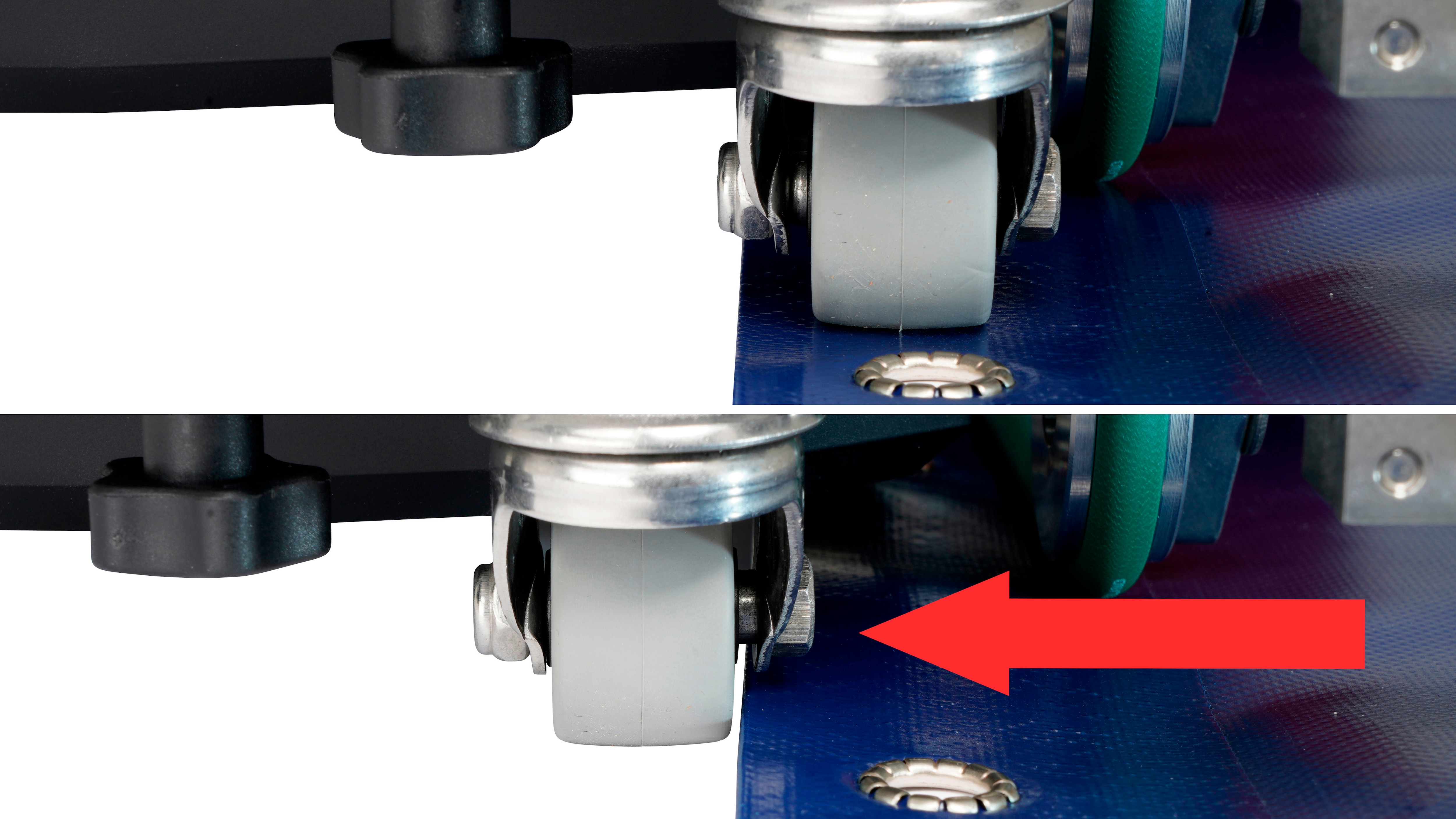

Troublesome snagging on obstacles such as eyelets, rivets or tensioning hooks is no longer a problem when using the UNIPLAN 500 for overlap welding. If something gets in your way, simply move the UNIPLAN 500 swivel castor wheel by hand and avoid the obstacle.

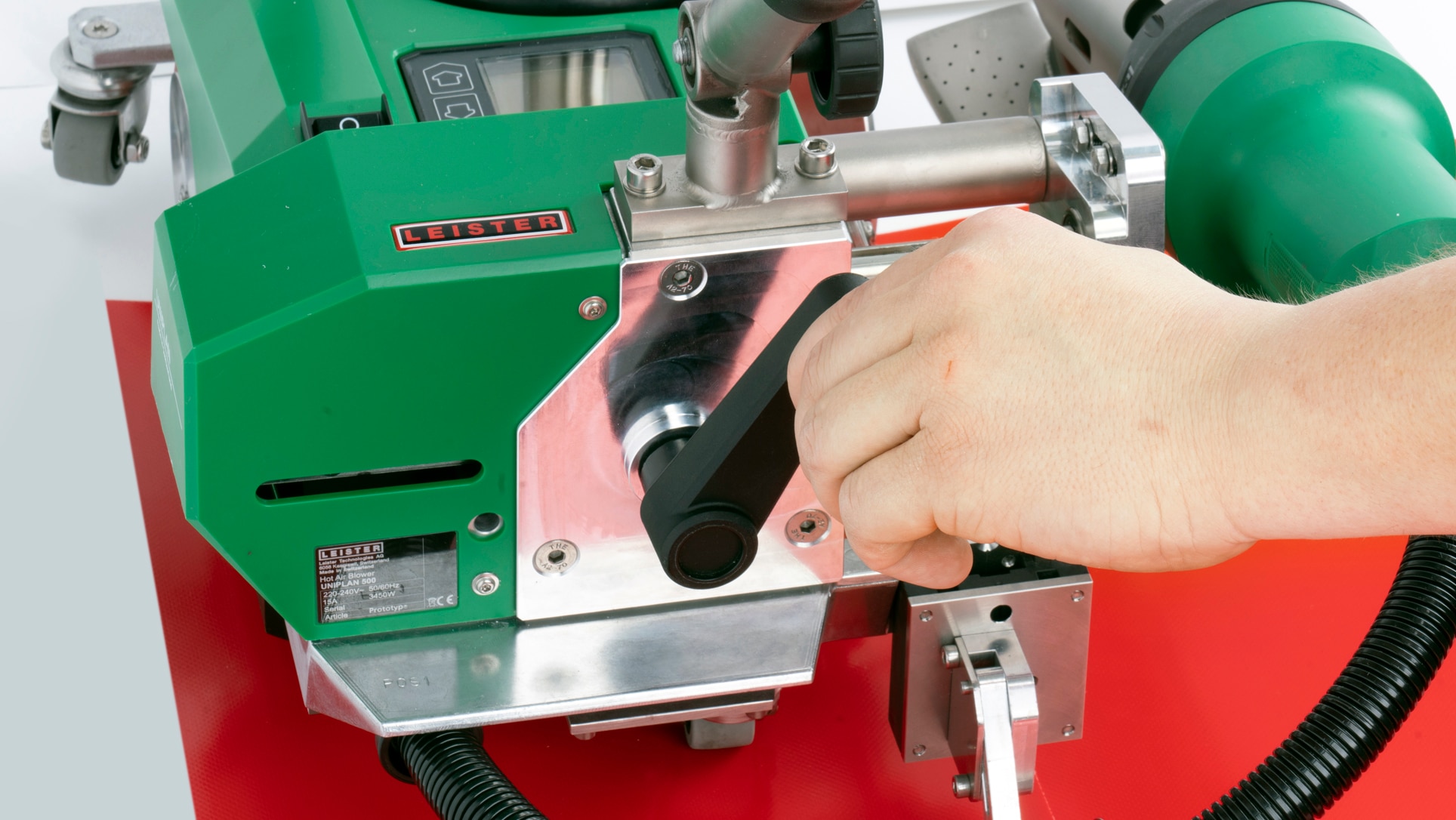

On the UNIPLAN 500 welder, users can change from overlap welding to hem or pipe welding in one easy step using a handle and without needing any tools.

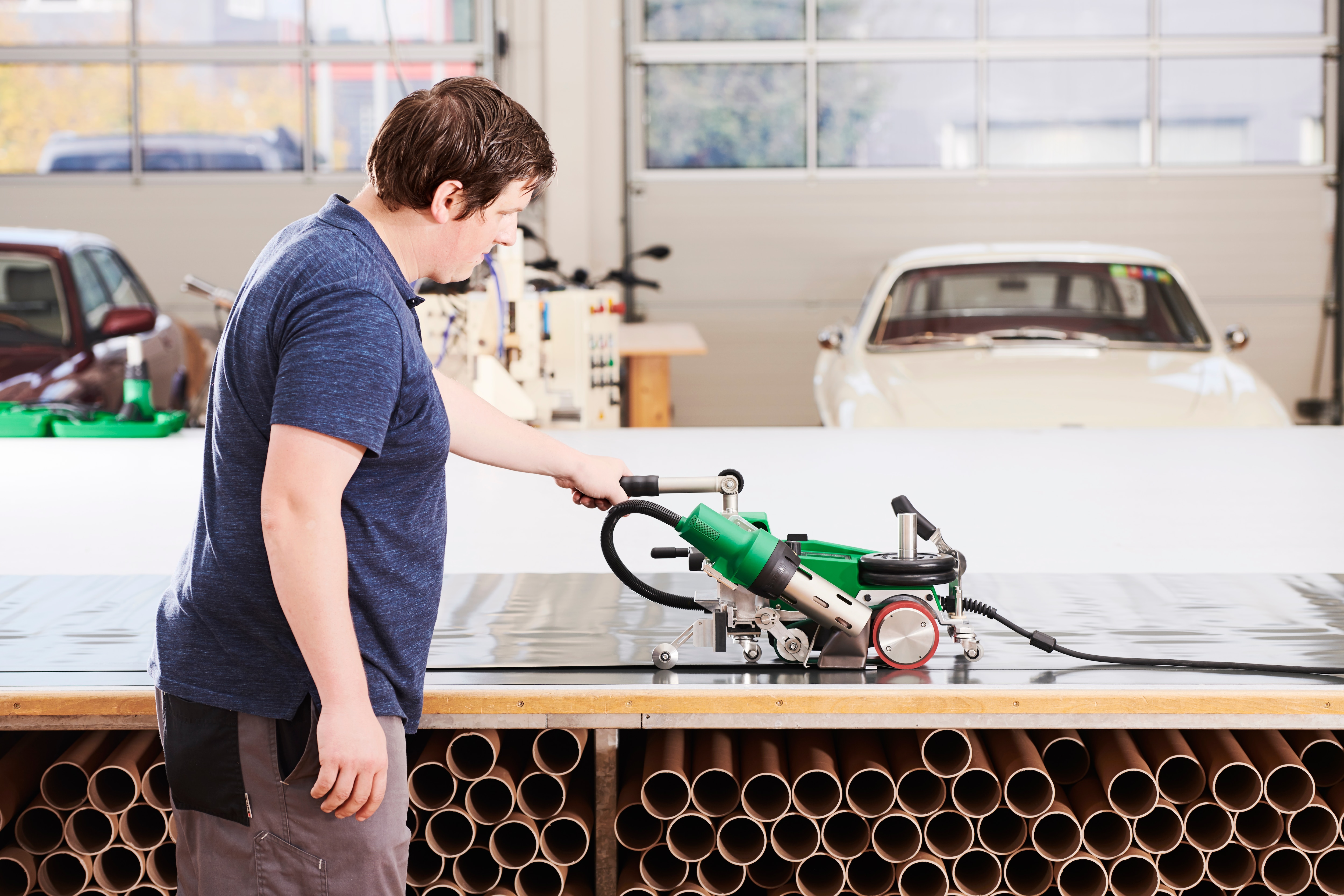

The Hot Air Blower - Air Heater on the UNIPLAN 500 is brushless and therefore maintenance-free. Thanks to its powerful blower motor, the UNIPLAN 500 achieves a significantly higher welding performance than conventional automatic welding machines. The maximum speed of the automatic welder is an impressive 16 meters per minute (52.5 ft/min).

You operate the UNIPLAN 500 with ease via an intuitively designed display. Set and save material-specific parameters for identical work quickly. This saves you time for future projects.