Author: Anja Wieder, Corporate Communication Manager, Leister Group

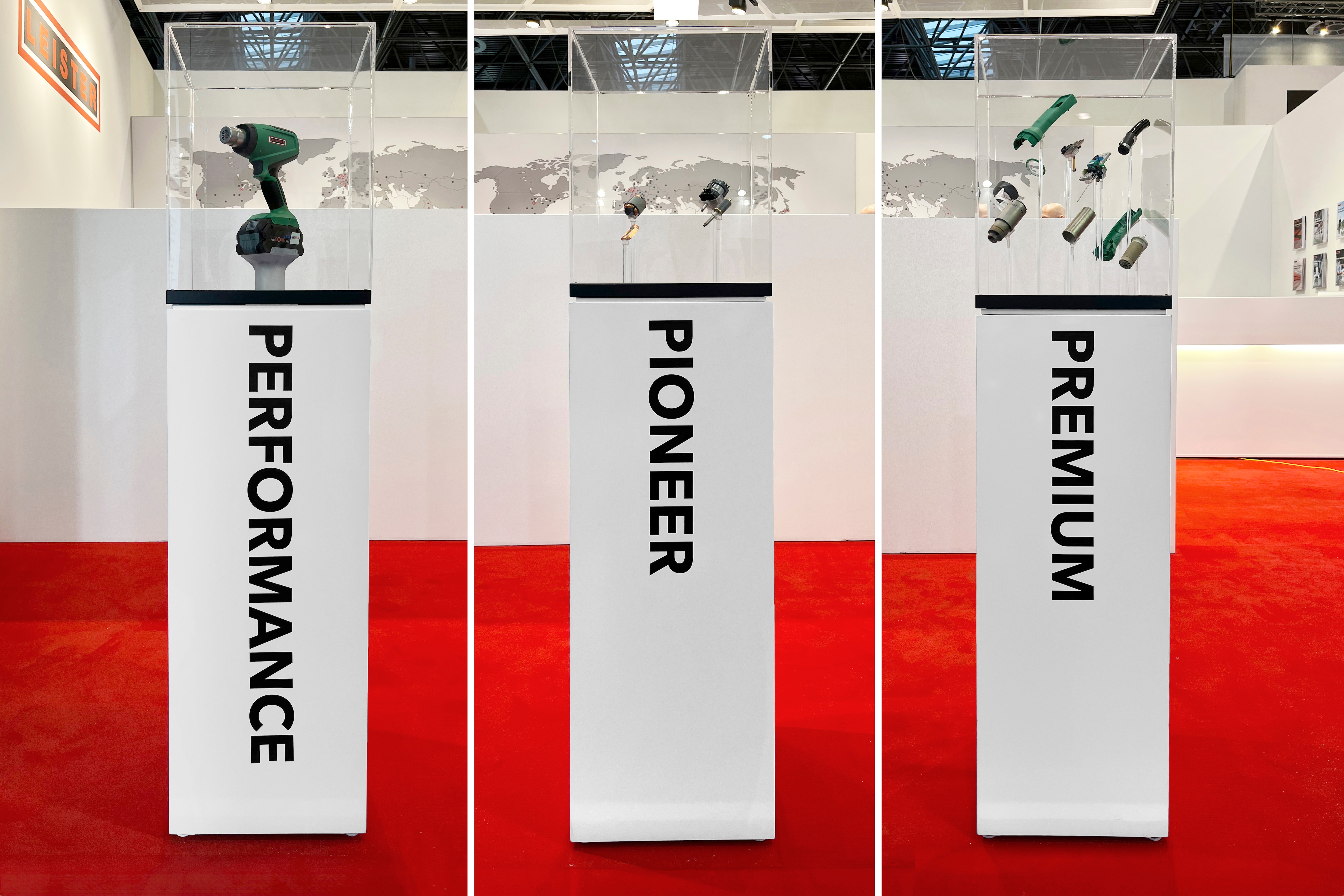

From October 8–15, 2025, Leister will be the go-to destination in Hall 11, Booth E16 for anyone who welds, heats, or forms plastic. Already during the first days of the show, the crowds are strong–and so is the curiosity. No surprise there: Leister is presenting not only exciting live demonstrations but also several product premieres that are drawing attention across the industry. And the brand-new booth design–spanning an impressive 124 m²–makes a bold statement.

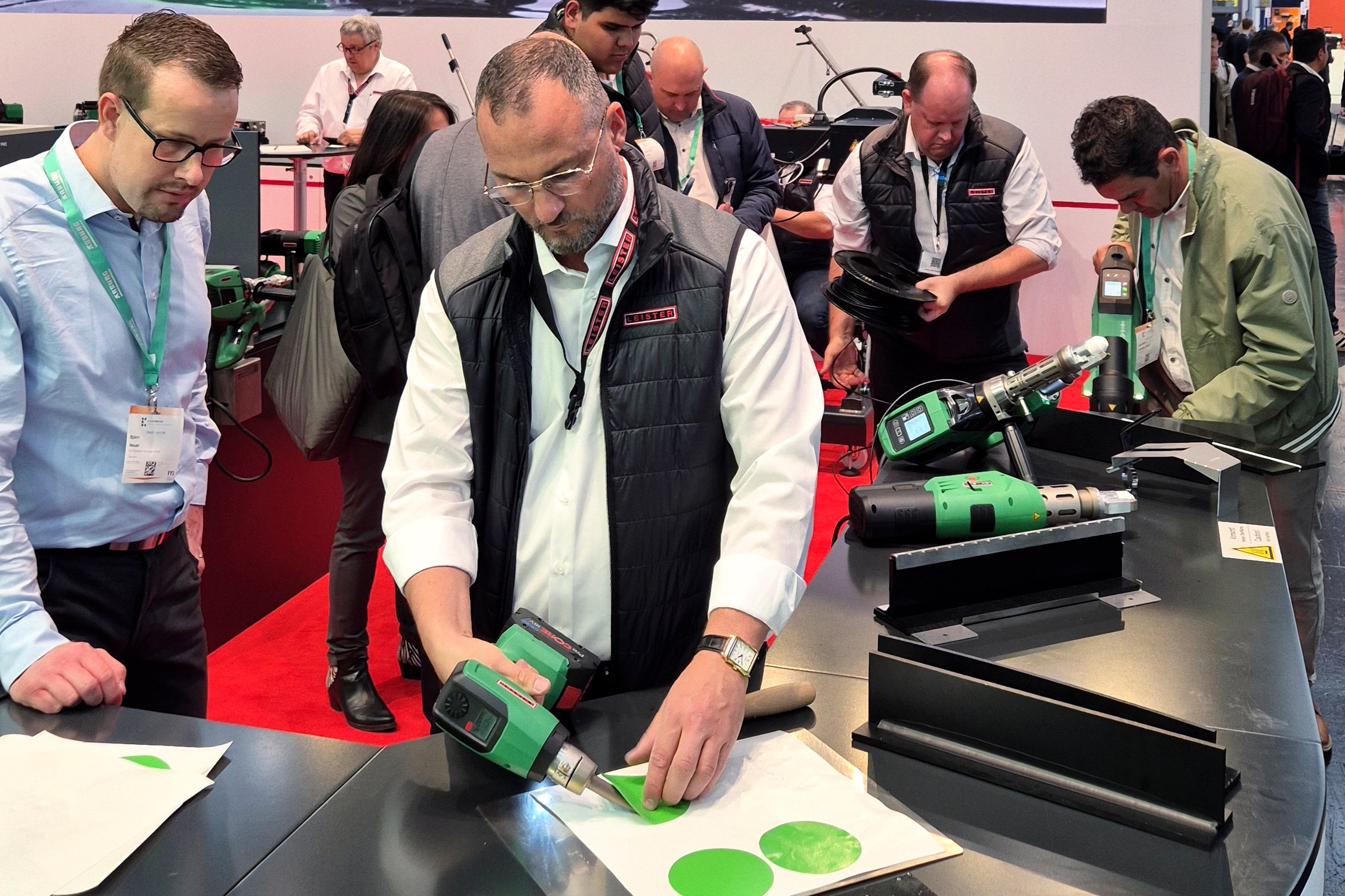

Welding Station Draws the Crowd

“The crowd is especially strong at the welding station, where the extruders and the NEXHEAT are demonstrated live. That draws a lot of interest and attention from trade show visitors. Customers are also impressed by our booth–especially the large screen and the new NEXHEAT,” says Roland von Ah, Head of Sales Partner Program at Leister International AG.

Welding with Battery Power

A clear highlight is the new NEXHEAT 300 A-LP, a cordless handheld welder that combines maximum mobility with precise performance. Whether for roofing, flooring, textiles, or civil engineering, it offers temperature control from 50 to 500 °C, a digital display, and an integrated LED light. The result: ultimate freedom on the job site without compromising weld quality. A true milestone for anyone who wants to work independently and powerfully-without limits.

“Finally, there’s a cordless welder that keeps a stable temperature all the way until the battery runs out. The flexibility on construction sites-without having to look for a place to plug in–is fantastic,” remarks a customer at the Leister booth.