Droptec Drones Welding with Laser

Success Stories24 Jun 2019

A loud buzzing sound is heard in the air... Is it a swarm of bees? No, the buzzing sounds too unnatural for it to be bees. Finally, we look into the air to see what it is: a drone. What used to be an uncommon thing to see, has now become part of everyday life.

Protective film for cartridges welded with LEISTER laser welding system

The net that wraps itself around the drone and disables it, is pressed into plastic cartridges. To protect the cartridges, Droptec uses a LEISTER laser system to weld the film. When this laser system was at Leister for service work, Droptec needed a quick solution to avoid delivery delays.

Laser from Droptec back in operation

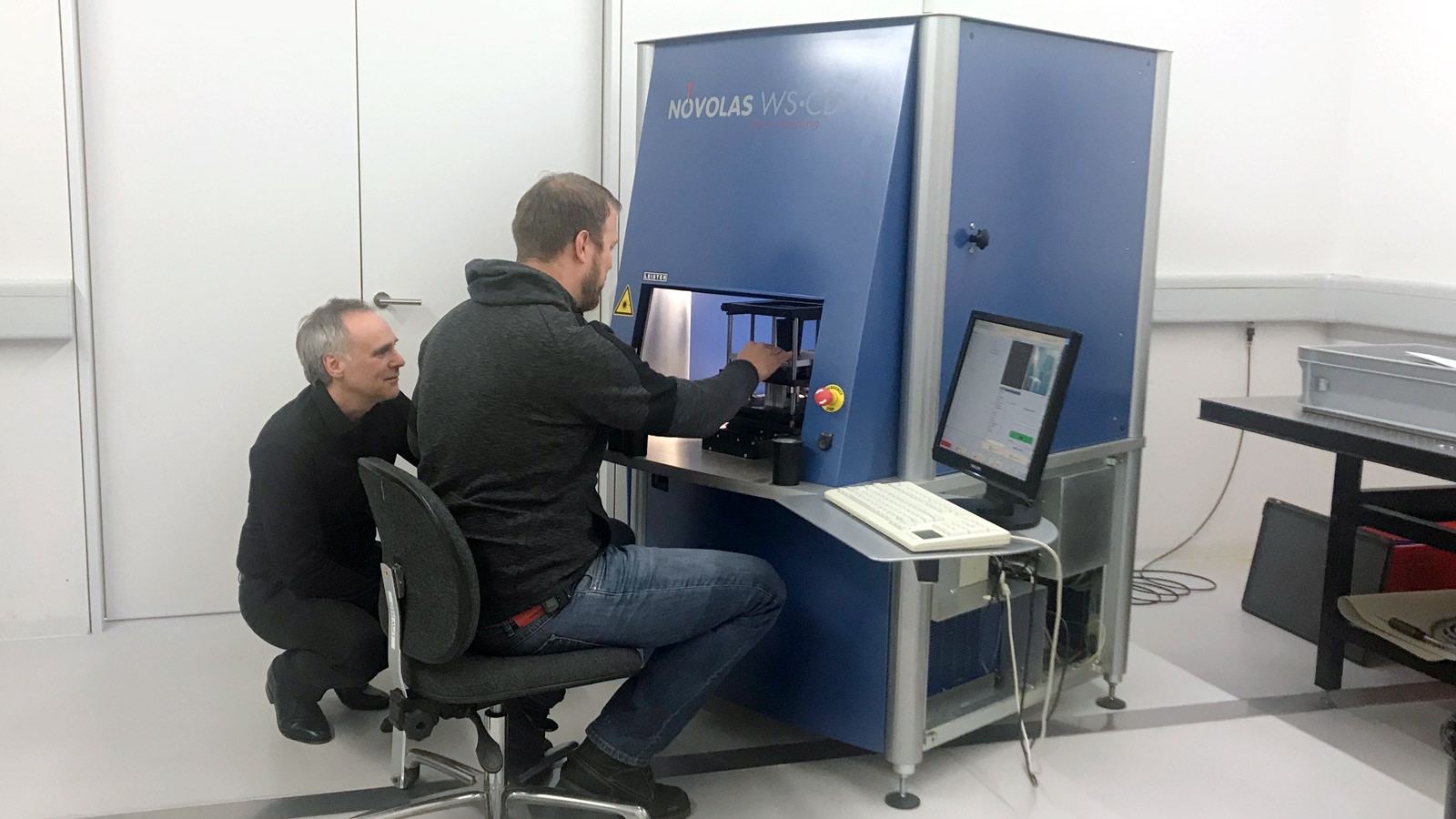

From left to right: Michael Werner, International Sales Engineer Leister and Philipp Furrer, responsible for development and production at Droptec GmbH, laser welding the Dropster cartridges in the laser laboratory at Leister Technologies AG in Kaegiswil, Switzerland.