Leister Technologies AG presents new products at the K-messe

Leister Technologies AG will present new products for various plastic welding and heating applications at the K-Messe trade fair in Düsseldorf from October 16th to 23rd. The Leister exhibit will be at Stand 22 in Hall 11.

Sealing roofs – semi-automatic hot-air welder UNIDRIVE 500

Leister Plastic Fabrication, Roofing & Flooring (PRF) business line professionals have developed the UNIDRIVE 500, a new semi-automatic hot-air welder for sealing flat and pitched roofs. With its dual drive and a nozzle rotates from left to right, the UNIDRIVE 500 is especially suitable for welding close to the edge and where space is limited.

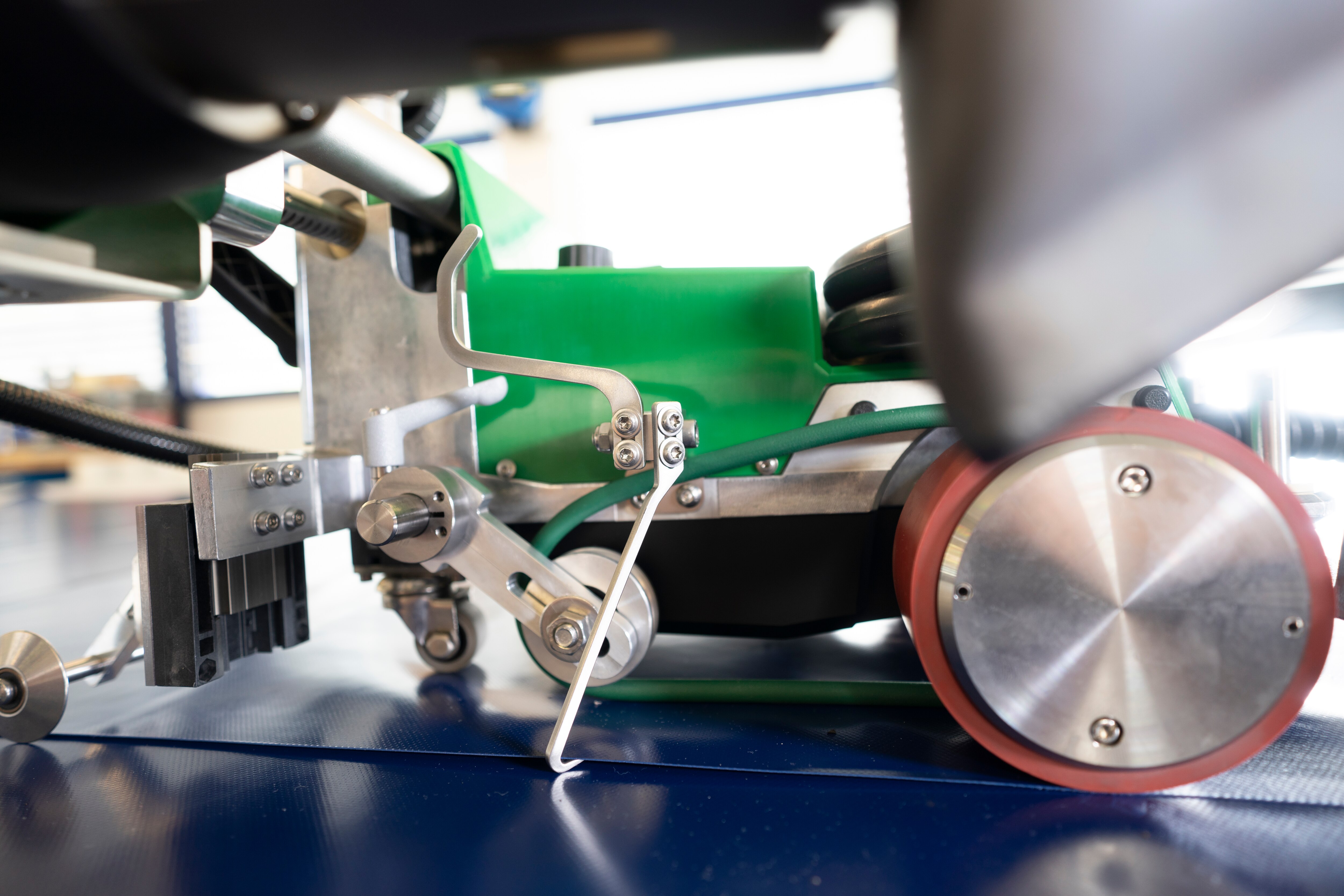

Welding of advertising banners, tents and truck tarpaulins – UNIPLAN 300 and UNIPLAN 500

UNIPLAN 300 and UNIPLAN 500 are a new kind of automatic welder developed by the Leister Technical Textiles & Industrial Fabrics (TEX) business line and are used for overlap, seam and piping welding of advertising banners, tents and truck tarpaulins. The numbers 300 and 500 represent the two performance classes in which this automatic welder has been available since mid-August.

Welding of geomembranes – TWINNY T5 and TWINNY T7

TWINNY T5 and TWINNY T7 are two new automatic welders developed by the Leister GEO (Geomembranes) business line. They have been designed for welding geomembranes ranging between 0.5 and 2.5 millimeters in thickness. The automatic welders are distinguished by their ease of use. Moreover, their large castors make them suitable for working on uneven surfaces. T5 and T7 stand for the two performance classes in which the automatic welder has been sold since mid-August.

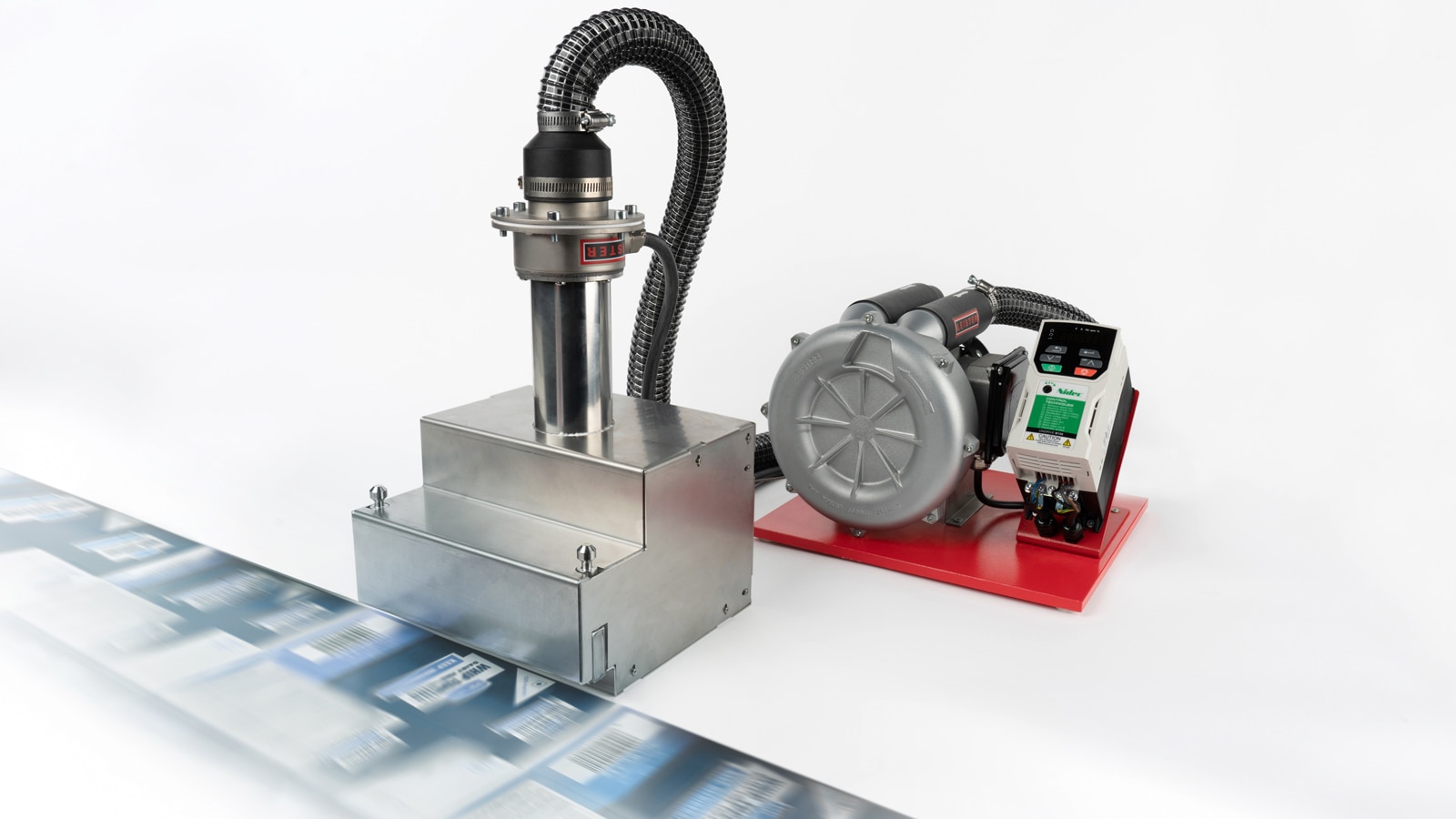

Industrial process heat – longitudinal seam welding of beverage cartons with hot air

Significant changes have recently occurred in the production of beverage cartons (Tetra Paks). The fossil fuels used to date are gradually being replaced by electricity generated from sustainable sources.

Laser plastic welding – laser system WS-AT and laser table-top system TTS

The Laser Plastic Welding (LPW) business unit engineers at Leister Technologies AG will present new laser-technology products and processes.

The variety of welding techniques will be separately presented visually in a compact form.

The latest development in laser plastic welding is a manual workstation for GLOBO welding with robots. Due to its size, the workstation will be presented in a film at the K-Messe.