Author: Antonio Colleroso, Process Heat Sales Specialist, Leister Technologies AG, Italy

ArcoDesign, a company based in Pianiga, Italy, are specialists in the design and production of exclusive wooden frames and surrounds for works of art and pictures. Because they are usually individually designed, orders are often custom-made. There is less demand for standard solutions. Nevertheless, ArcoDesign wants efficient production and is therefore constantly looking for ways to automate the processes as much as possible. The focus is on the quality of the handmade frames and the custom design.

Challenges Facing Professional Frame Manufacturers

During completion, ArcoDesign applies different colored film, with various technical properties, to the untreated wooden frames. These give the picture frames their characteristic and individual appearance. The wood is heated to a constant temperature to prevent defects when applying the heat sensitive film. The previous hot air blowers produced too high a temperature and could not be regulated. This damaged the picture frames.

“The hot air blowers we used to use were not from Leister. They could not maintain a constant temperature, causing the frames to overheat. This formed bubbles on the film and it was difficult to correct this,” explain Fernando Zanotto and Savino Pian, the owners of ArcoDesign. This hot air tool also had a short service life. They lasted barely a year.

So ArcoDesign decided to invest in a professional solution. Leister was chosen because it stands for quality and decades of experience in hot air applications.

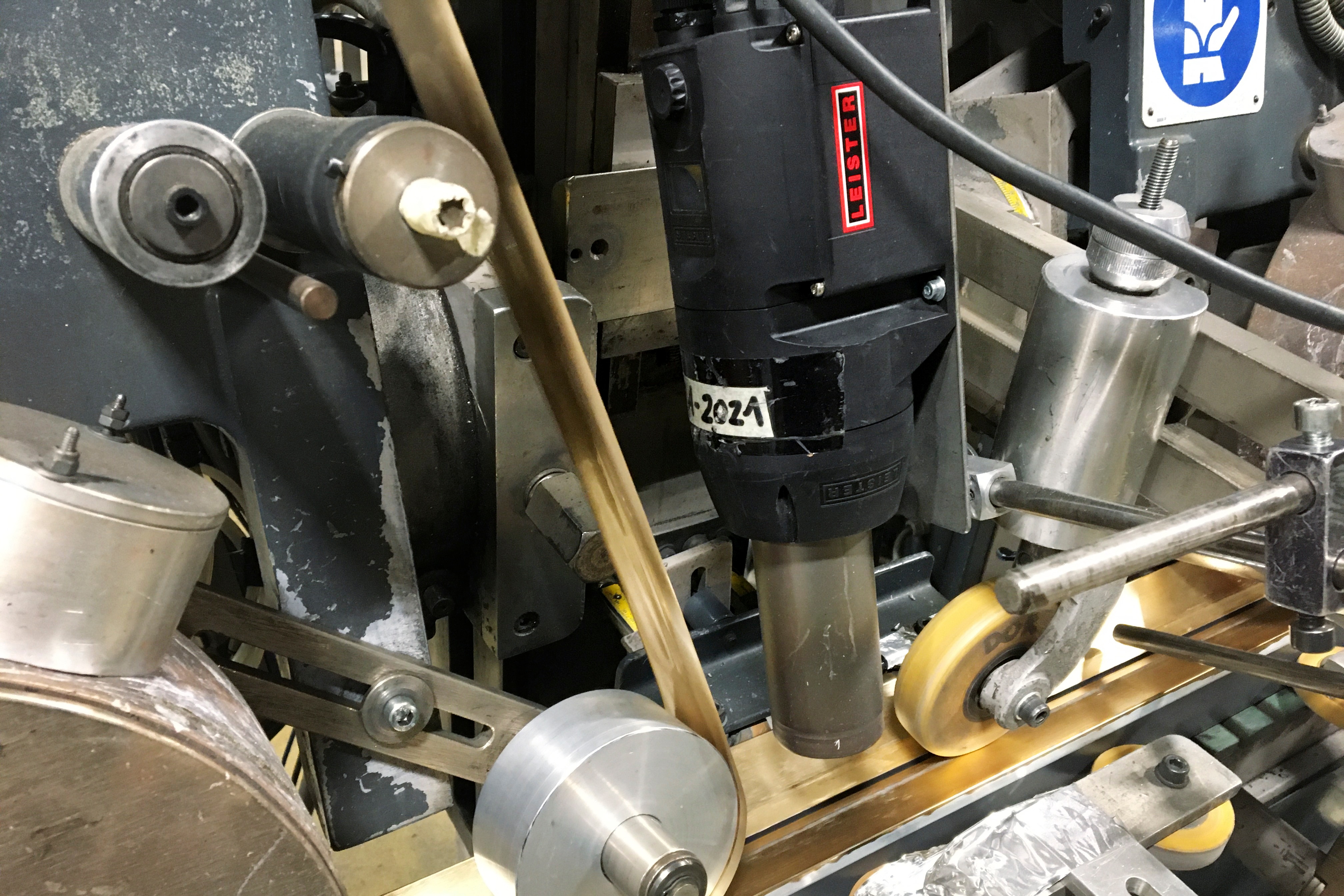

The technical sales staff at Leister Italy provided ArcoDesign with expert advice and recommended the MISTRAL 6 SYSTEM hot air blower. Why? Read on.

The Leister MISTRAL 6 SYSTEM Hot Air Blower for Reliable Continuous Operation

The MISTRAL 6 SYSTEM hot air blower from Leister has been especially developed for continuous operations in industrial applications. It brings the heat exactly where it is needed. The MISTRAL 6 SYSTEM heats up a hot air flow of up to 400 liters per minute up to 650 °C. In the SYSTEM version, you control the air temperature and air flow rate either via the air heater controller or the control panel on the system in which you have installed the hot air blower. Control is very user-friendly and guarantees you total repeatability and, therefore, process safety.