Author: Chloe Stambaugh, Marketing Associate, Leister Technologies USA

Turning Plastic into Possibility

At Pro Plastic Welding in Colorado, thermoplastics have become high-performance components for industries ranging from mining to manufacturing. The company delivers full-service plastic fabrication—including CNC machining, design, repairs, and 3D printing—built on a deep understanding of the trade and powered by state-of-the-art tools.

At the heart of their success: Leister extrusion welders. Whether tackling complex welds or navigating tight deadlines, Pro Plastic Welding counts on Leister for reliable, repeatable results. Their workshop even features Colorado’s only butt welder capable of joining 1" solid and 2" hollow plastic sheets in a single pass—a testament to their technical leadership.

Local Talent, Global Standards

True to their roots, the team partners with the local community college’s welding program to train the next generation of skilled professionals. Inside their facility, craftsmanship meets innovation through CNC routing, vacuum forming, extrusion welding, and custom plastic solutions. With Leister in the mix, they serve a diverse customer base with agility and precision.

Welding Challenges, Solved with Leister

Pro Plastic Welding puts Leister tools to work across high-demand projects:

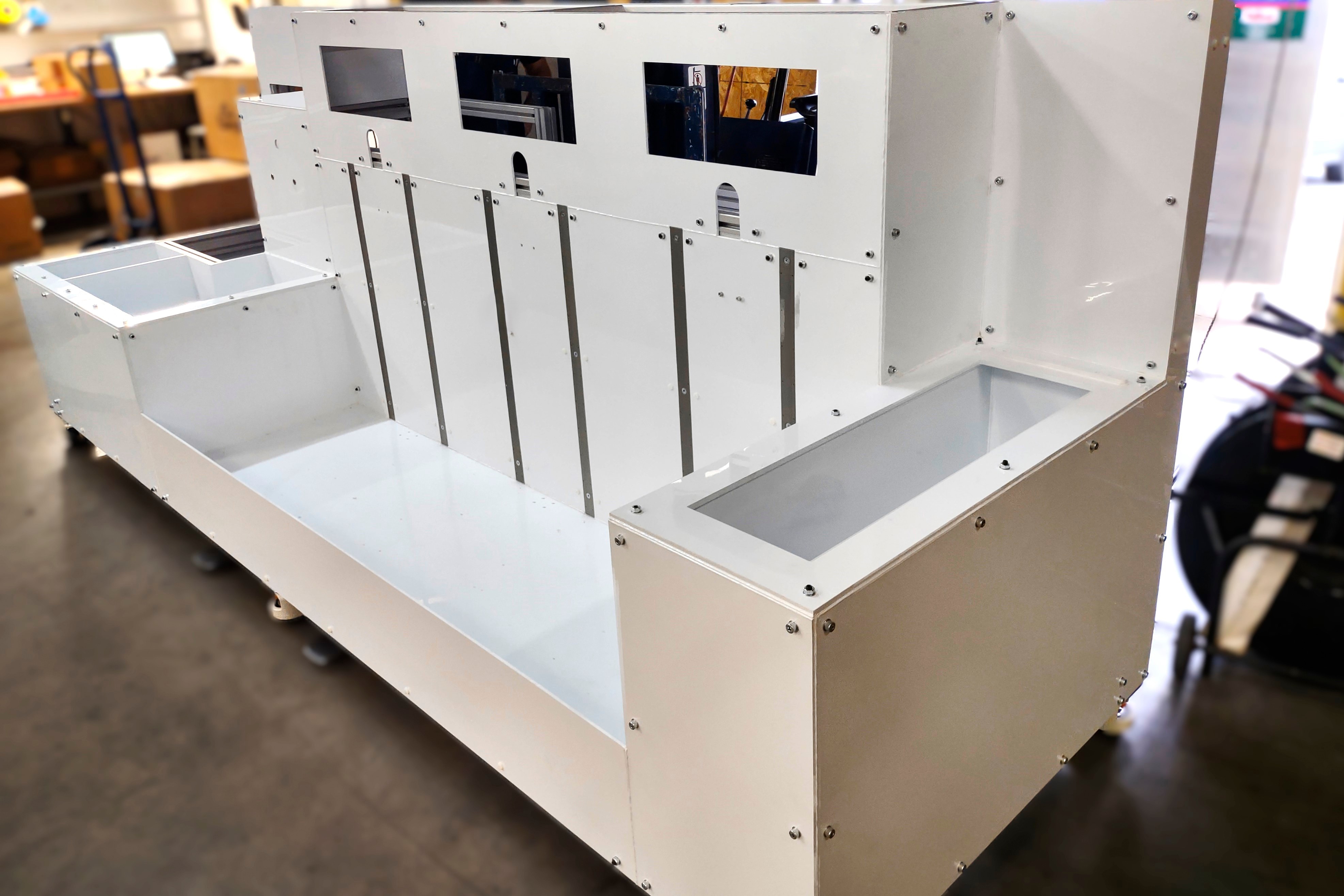

- Baptismal pool, HDPE ½": Confined spaces required a compact, powerful tool. FUSION 1 delivered seamless welds even in the tightest corners—proving its worth with every pass.

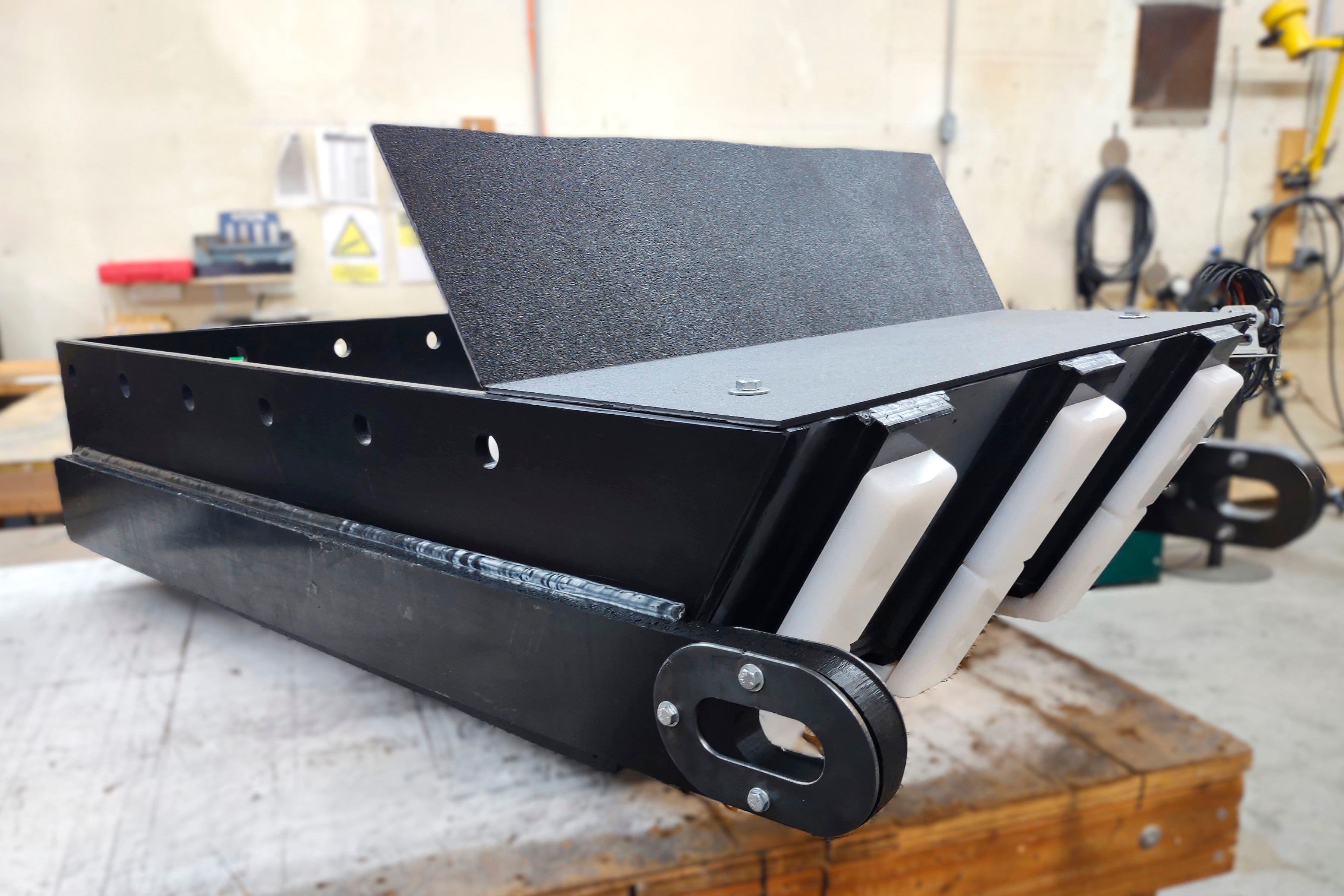

- Ground-penetrating radar sled, PE100 ¾": Designed for harsh terrains, this component needed extra-strong welds. WELDPLAST S2 PVC handled the heavy-duty challenge, producing smooth, solid seams built to last.

- Secondary containment system, PE100 ¾": Long seams and thick sheets called for endurance and speed. Again, the WELDPLAST S2 PVC impressed with its high feed rate and welding consistency.

These examples show the versatility and power of Leister tools—designed to adapt to demanding materials and applications.