The Four Requirements for a Utility Roof

- It should be permanently sealed to provide protection against external influences.

- It should be planted with vegetation to enable retention, hold water and provide relief for the storm sewer system.

- A photovoltaic system and a hot water generation system should be installed in order to generate a return.

- The vegetation is intended to create biodiversity and improve the microclimate in order to give the roof area back to nature.

Under the right conditions, flat roofs offer a great opportunity to transform protective roofs into utility roofs. These days, building owners no longer have to choose between photovoltaic systems and green roofs, as a combination of both is particularly beneficial.

Safe Welding of Roof Sealing Sheets

Due to the increased requirements and multiple uses, a permanently watertight flat roof is essential. It is therefore particularly important to use good quality welding equipment.

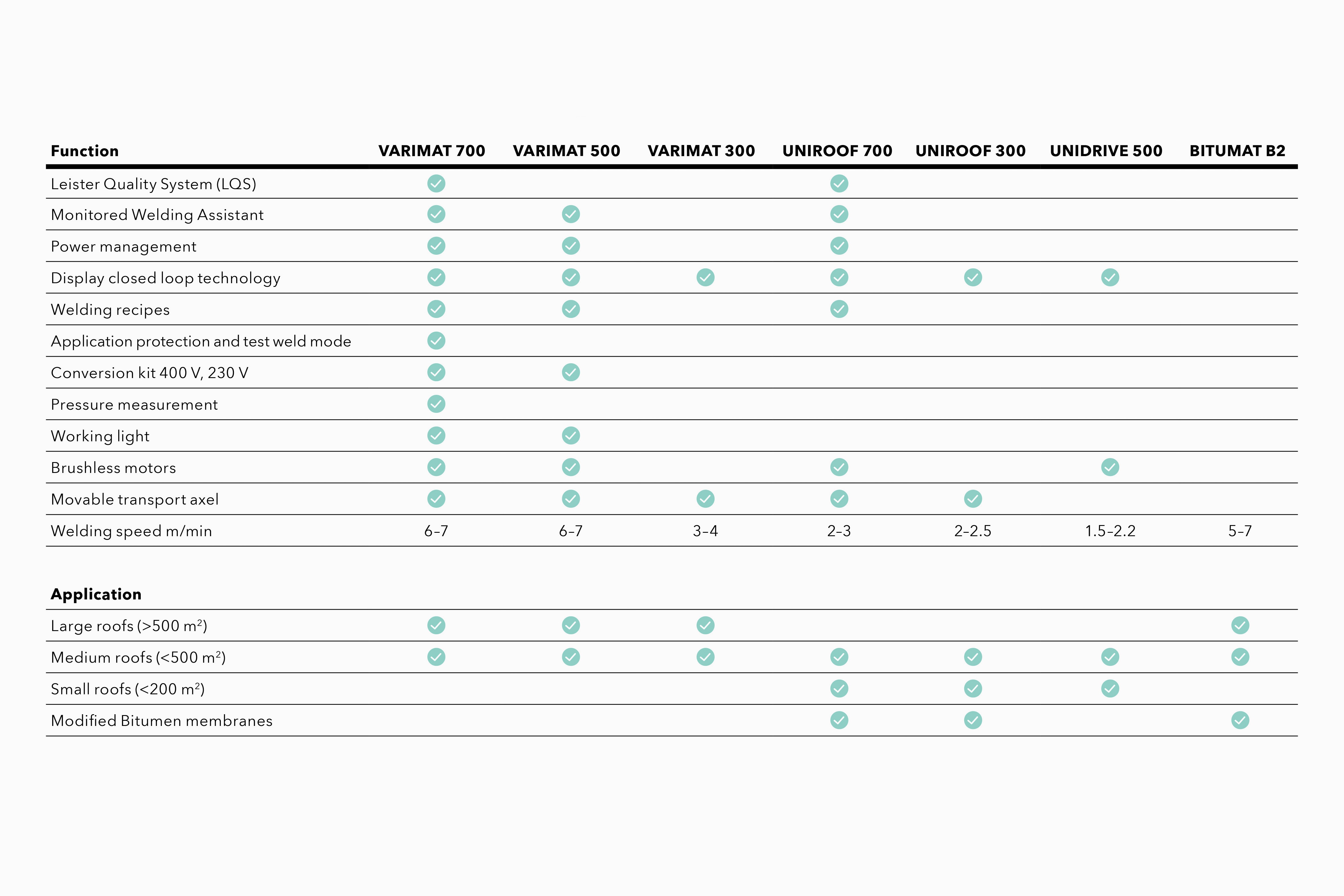

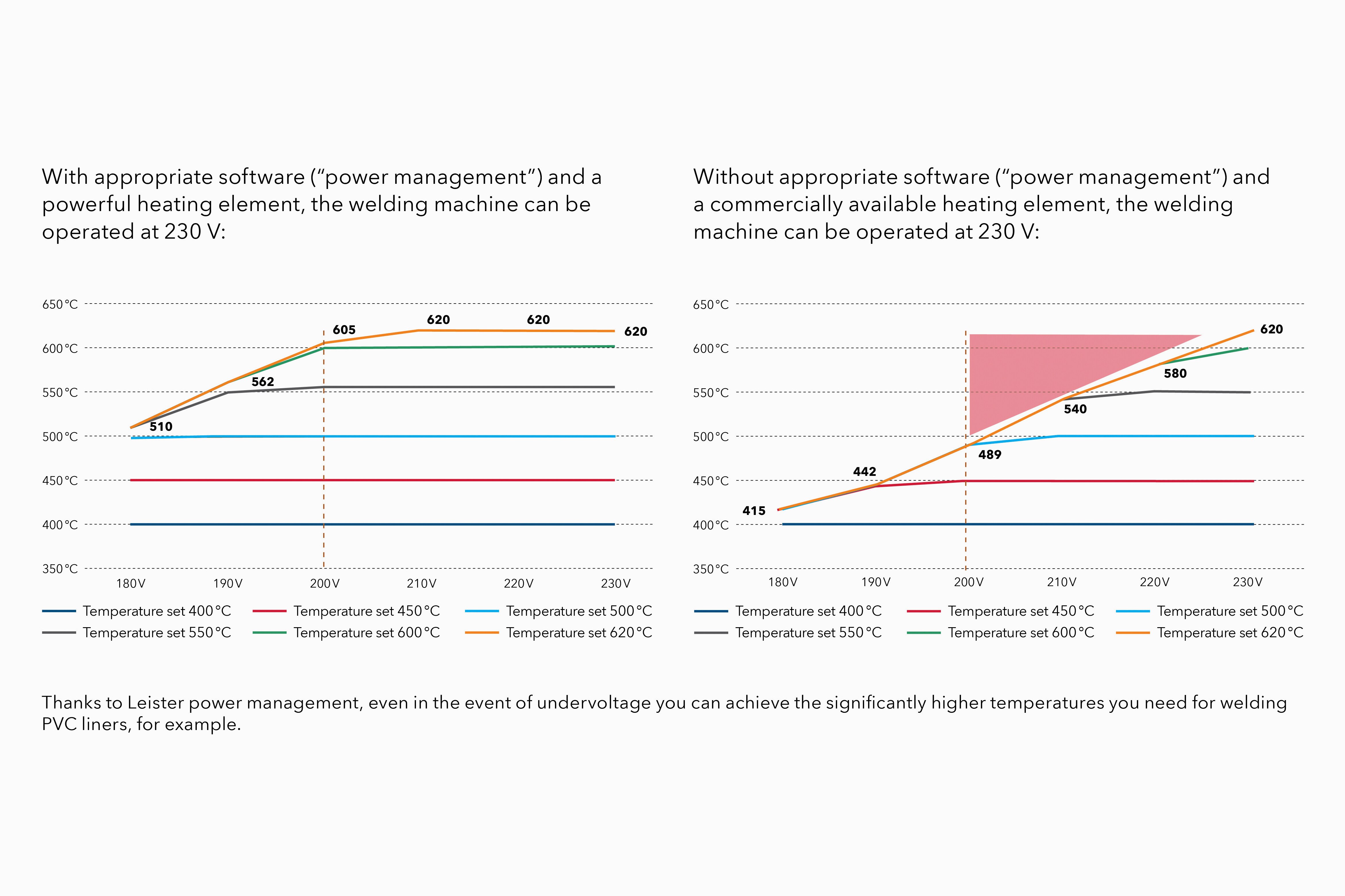

The VARIMAT 700, VARIMAT 500 and UNIROOF 700 automatic welding machines from Leister are equipped with the Leister Quality System (LQS), Power Management and Monitored Welding Assistant for quality assurance.

Product Overview of Flat Roof Welding Machines