Fluidic Components Welding

Sensitive parts such as fluid-carrying components can be welded together precisely, permanently, firmly and above all contamination-free.

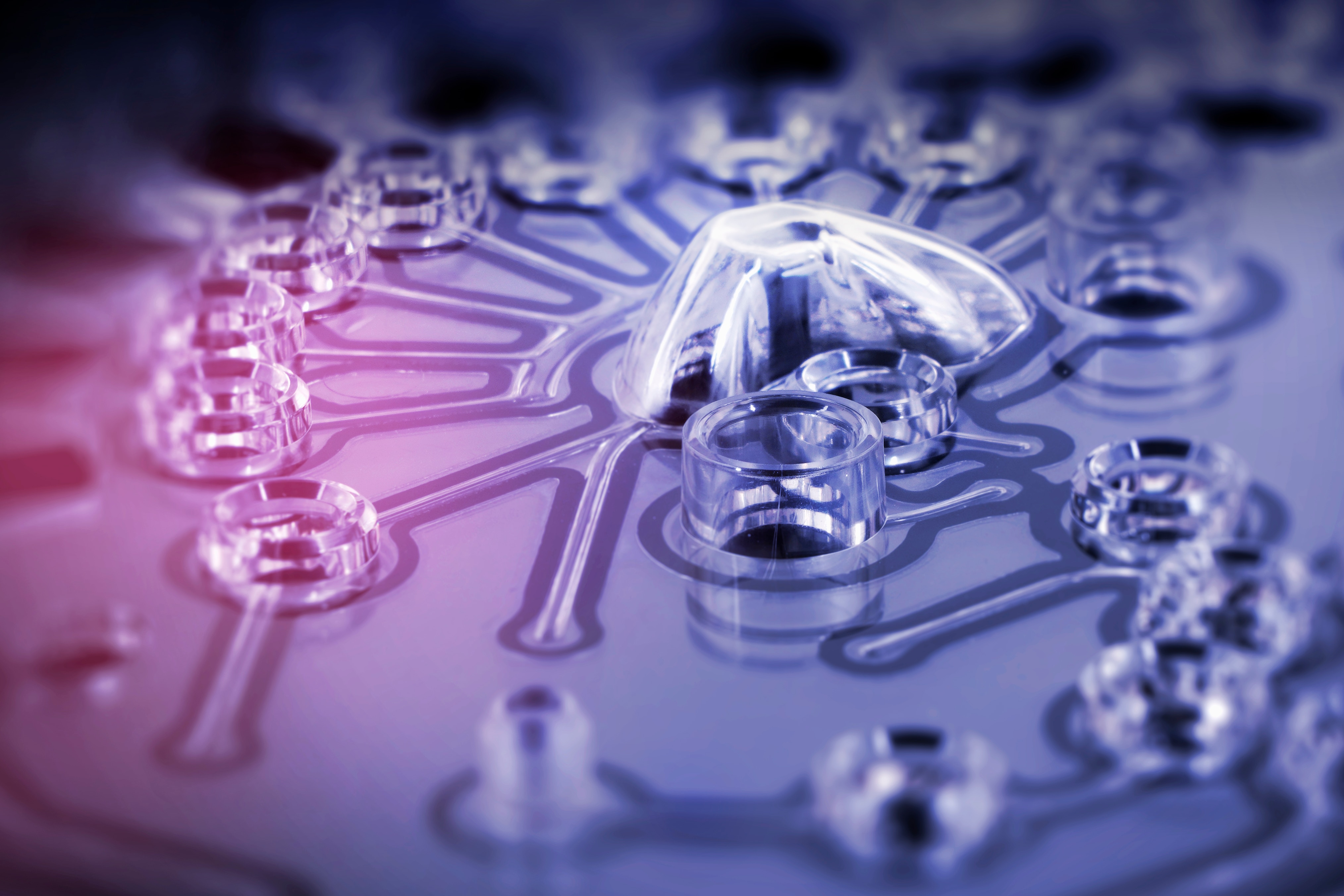

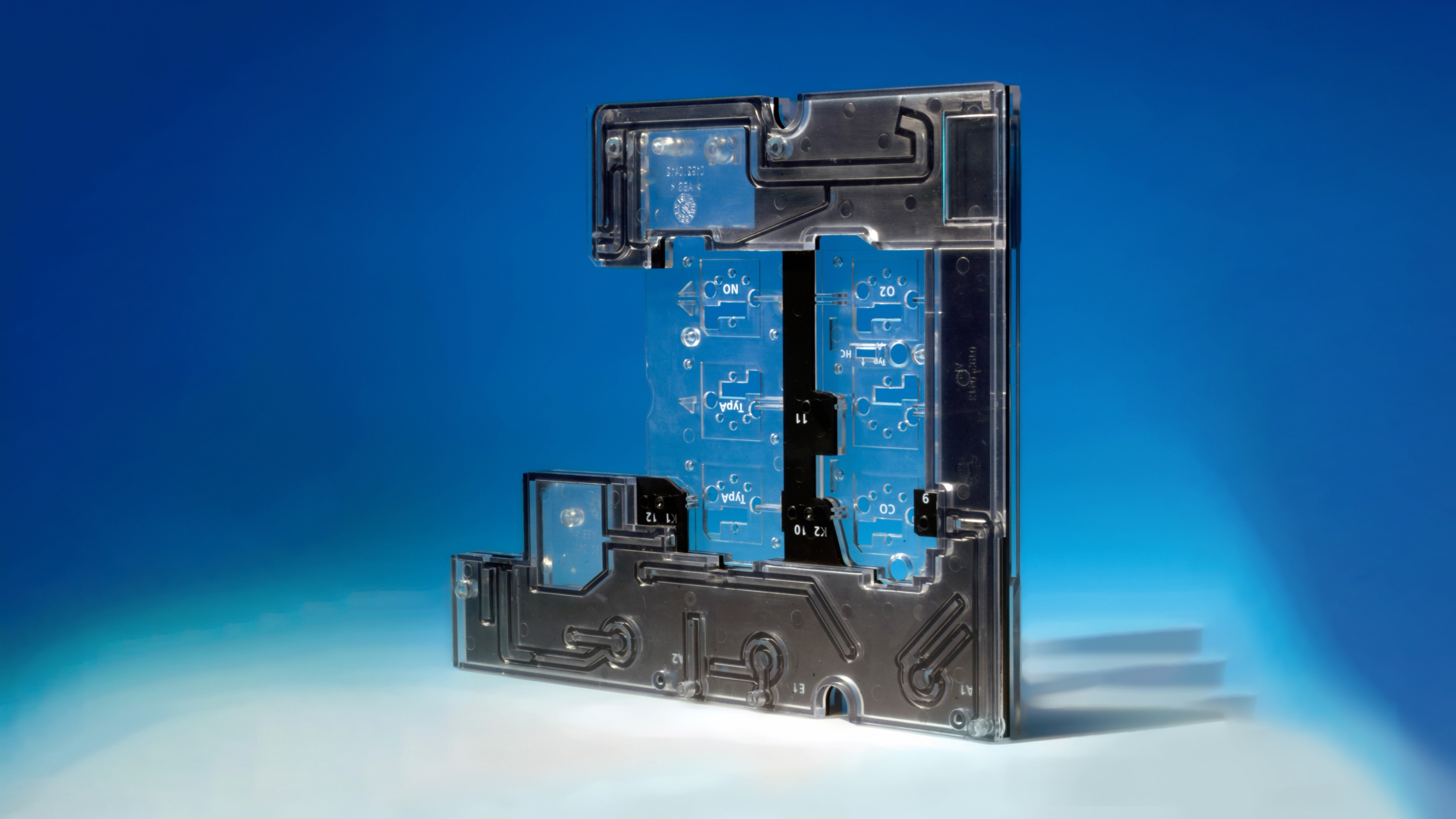

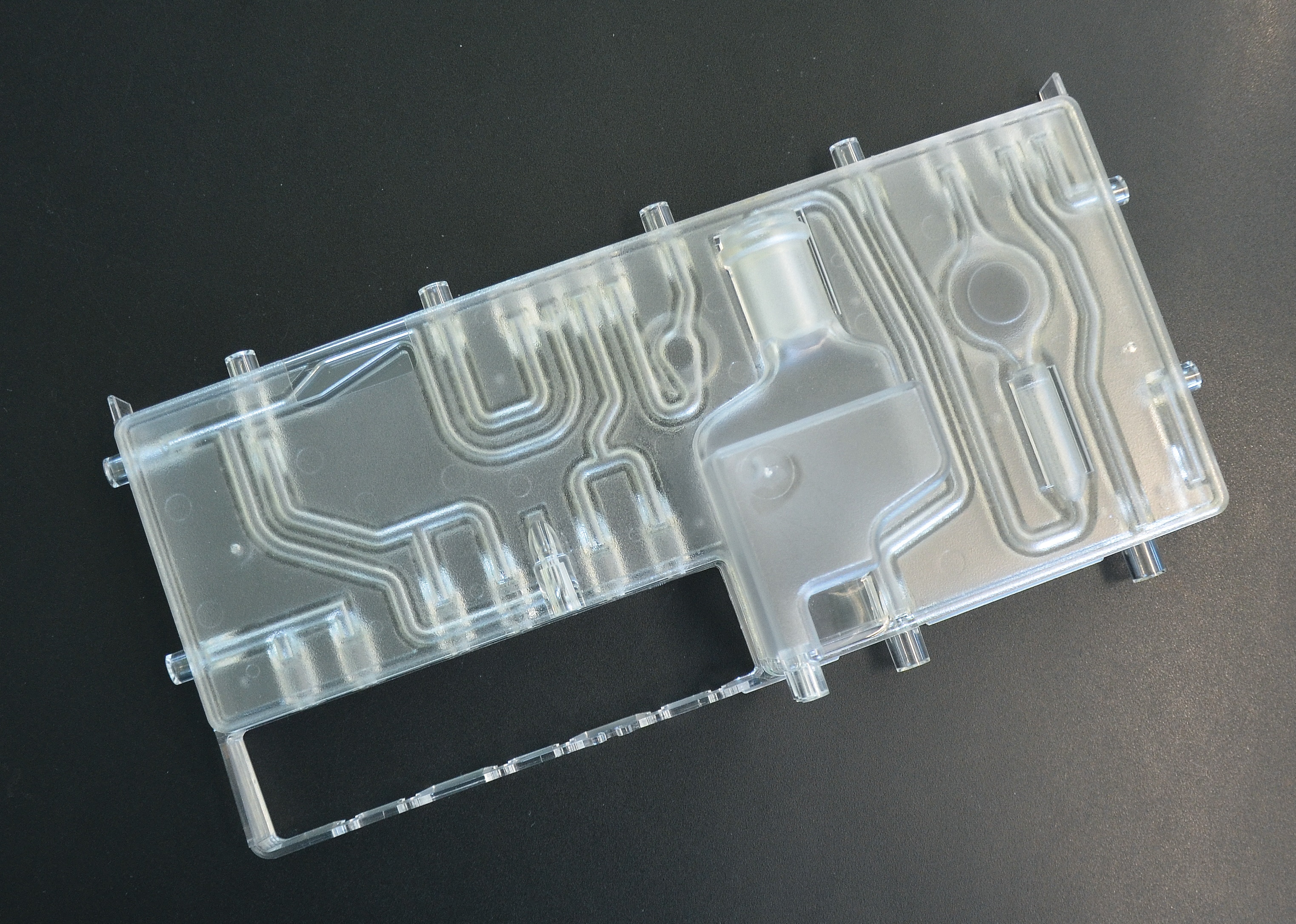

The gas is fed into a cassette where it is divided into several channels for analysis. The channels must be hermetically sealed. Contamination-free laser welding is an ideal and fast welding process, which has proven itself in practice. A weld seam length of several meters can be welded in seconds.

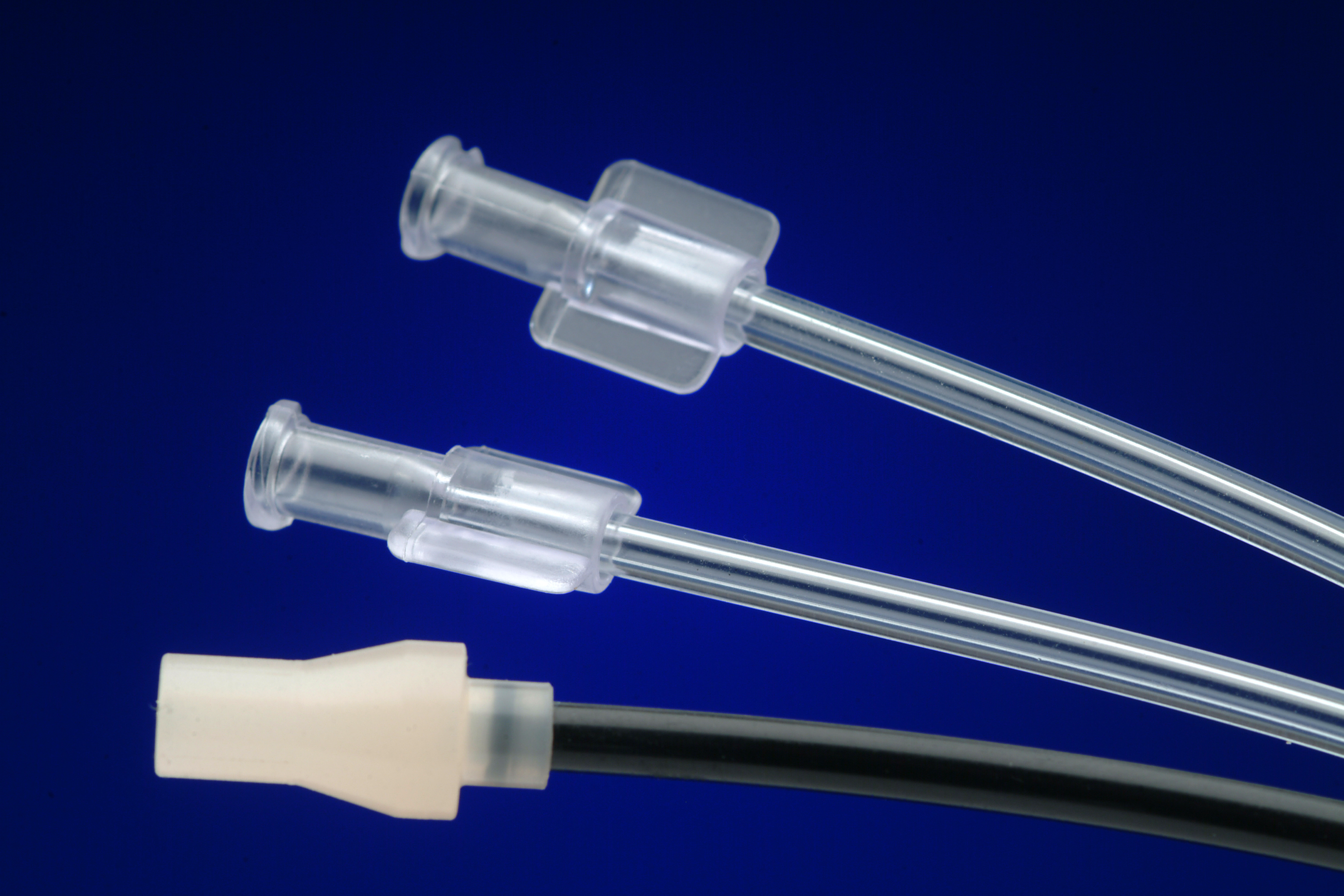

The thermal and mechanical load on the components is small compared to other welding processes and therefore very suitable for the medical industry. Infusion pumps are only one of many examples in this category. It is important that the channels through which the drugs are transported are hermetically sealed without contaminating them.

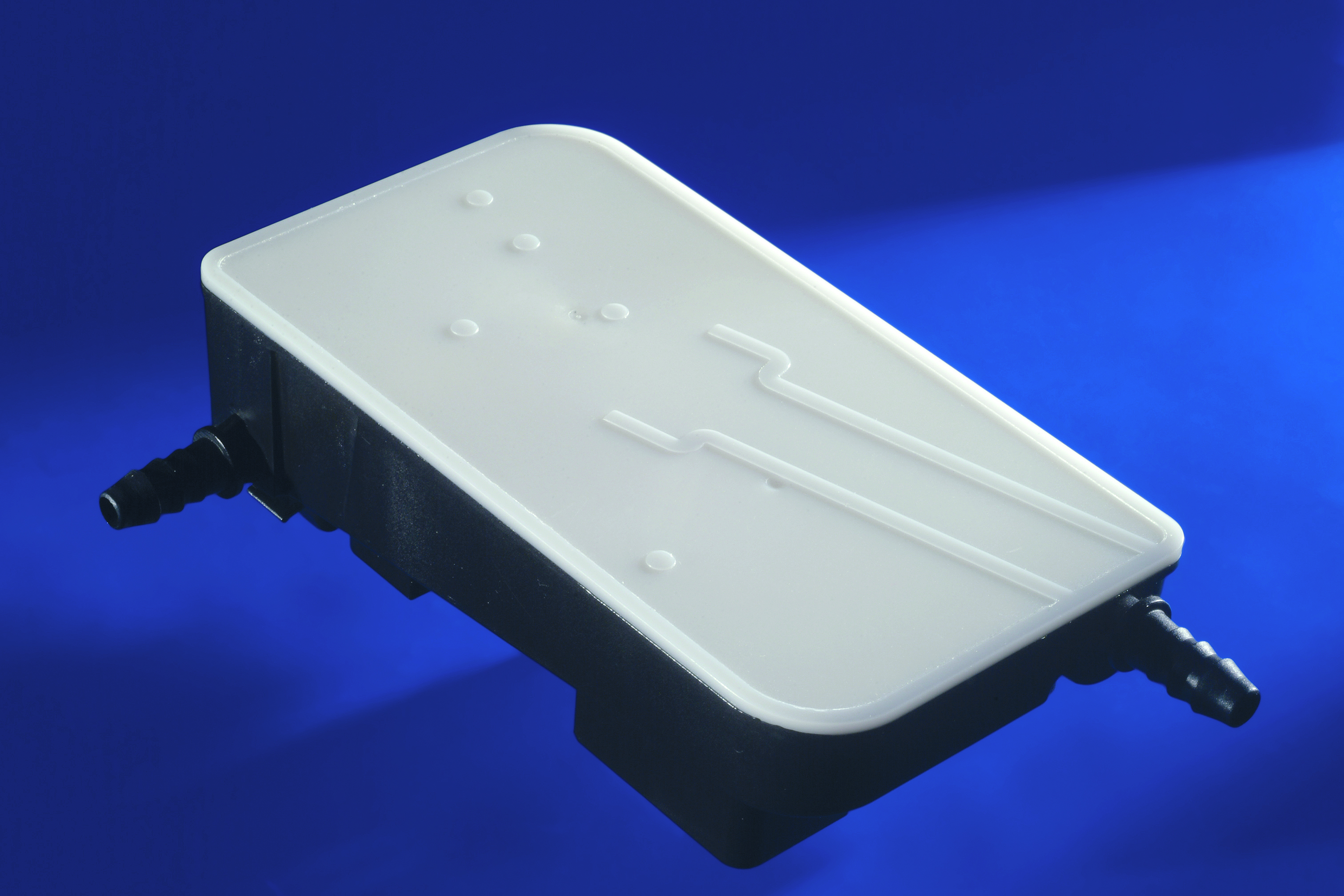

The Liquid Vapor Separator (LVS) is a good example in this. The LVS is installed between the fuel tank system and an activated carbon filter, and it separates liquid fuel from the vapor. For the sake of the environment, the fuel is fed back into the tank, while the gases are filtered and released into the environment.

In the case of the cartridge shown, an absorber is applied to the surface of the components before welding. This can be applied individually and converts the laser power applied into heat energy only locally. This means that two transparent components can also be welded with the laser.