In principle, the deburring of injection-molded plastic components is also classified as a forming process. The fine but unsightly burrs are heated to such an extent that they melt and reshape under the effect of surface tension.

If several plastic parts or a sprue and a plastic part are joined together by narrow webs after the injection or blow moulding process, they can be separated by the targeted use of hot air.

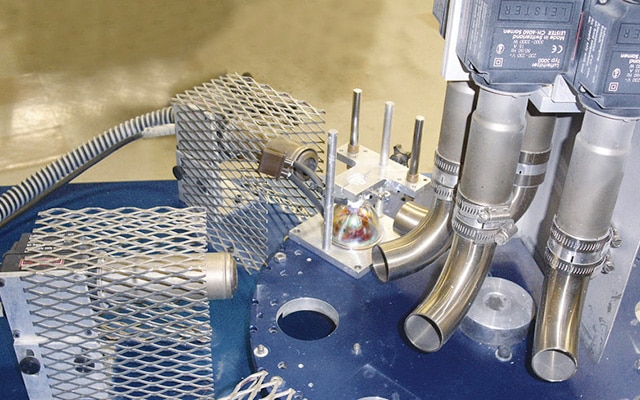

When processing thermoplastic pipes, e.g. g. tinsmith and/or sheet-metal work, the tubes are molded with hot air. To do this, the tube is first heated and then shaped into the desired form. After cooling, the tube retains its new shape.