New Approaches in Composite Processing

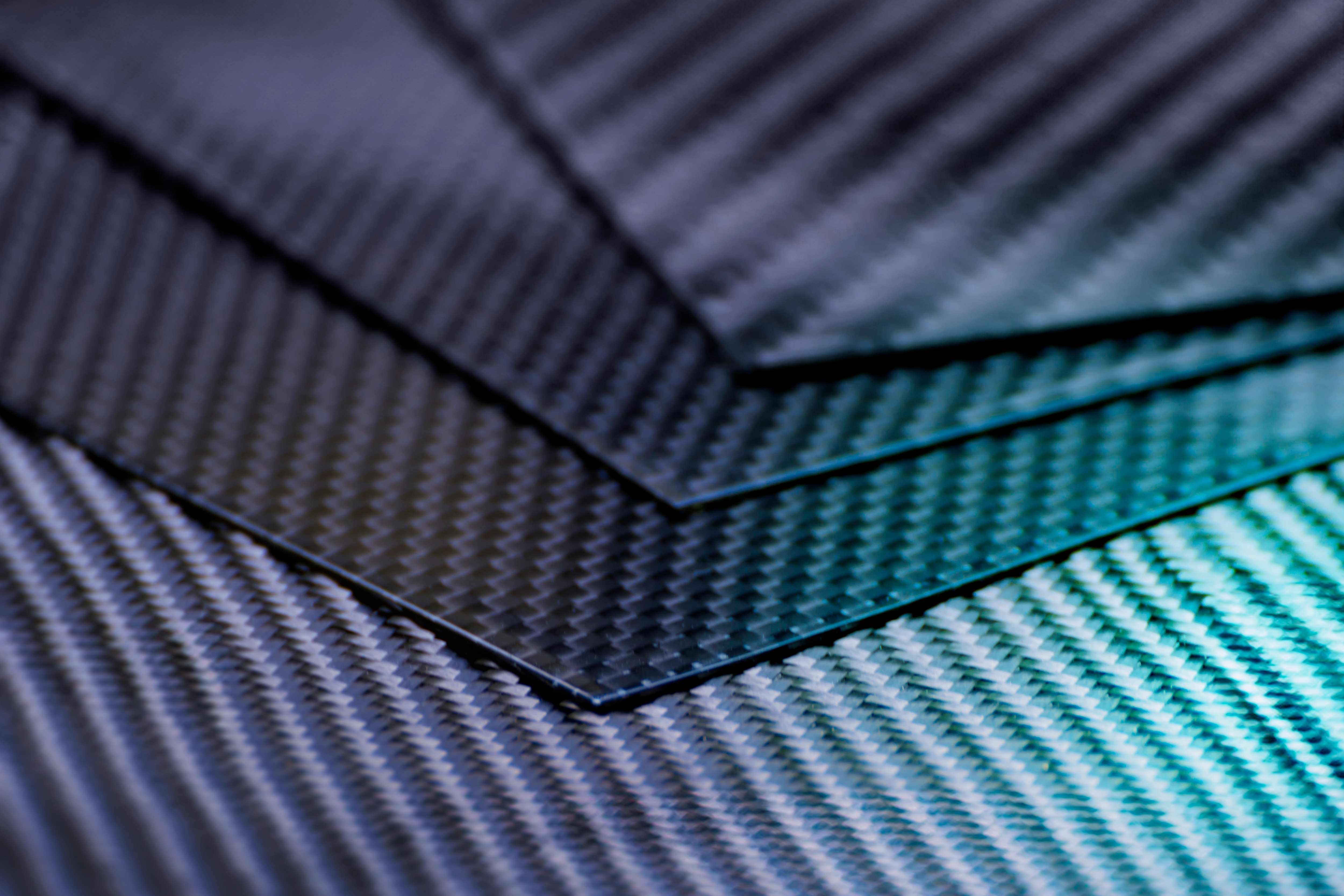

Thermoplastic organosheets are gaining ground – in aircraft construction, the automotive industry, and high-end electronics applications. These fiber-reinforced semi-finished products combine the advantages of thermoplastics, such as low weight and good formability, with the high mechanical strength of fiber composites. However, anyone wanting to exploit the full potential of these organosheets needs to understand the importance of heating them correctly before forming. Leister infrared heaters enable particularly precise and energy-efficient heating of the materials in this application.

Our Leister expertise demonstrates in practice:

- which IR emitters are truly suitable (including a detailed comparison),

- why the radiation wavelength is a driver of efficiency,

- how to ensure temperature homogeneity even with complex geometries,

- which role zone control plays in IR ovens,

- and what “pixelization” means in composite processing.

Who will Benefit Most from this Expertise?

For OEMs in mechanical engineering, plant manufacturers specializing in injection molding solutions, and end users in the automotive, aviation, and sports industries who want to mass produce complex composite structures – reliably, energy-efficiently, and with consistent quality.