Author: Anja Wieder, Corporate Communication Manager, Leister Group

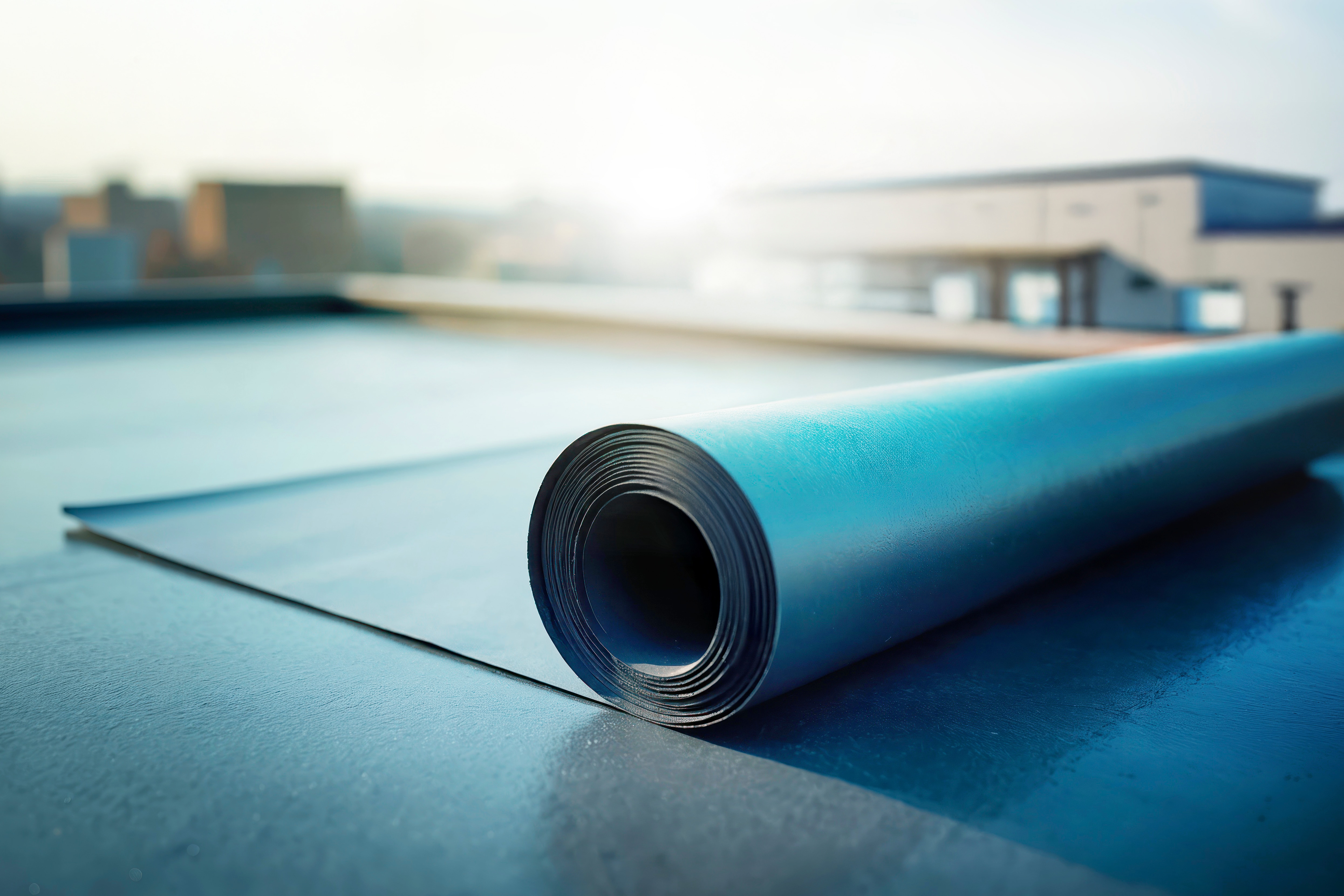

Whether it’s a PVC roofing membrane or a TPO sheet, Leister’s new technical guide offers comprehensive insights into plastic welding techniques for roofing applications. It explains how to properly adjust welding parameters, prepare seams correctly, and visually assess the quality of welded seams.

A special focus is placed on avoiding common welding mistakes – such as excessive temperatures, incorrect travel speeds, or insufficient cleaning. The guide also offers practical guidance on dealing with the oxidation layer often found on TPO membranes and how to remove it effectively.

Practical Expertise for Reliable Roof Sealing

This technical guide is intended for contractors, roofers, and technical professionals who work with thermoplastic roofing membranes – such as PVC, TPO, FPO, EPDM, EVA, ECB, or PIB – and need to weld them safely and permanently. Inside, readers will find:

- Reference values for initial welding parameters in Europe and the US

- Tips for checking seam tightness and performing seam inspections

- Recommendations for preventing blistering in TPO membranes

- Instructions for correctly setting temperature, airflow, and speed

- Guidelines for maintaining welding equipment and ensuring quality control

Download the Guide for Free and Weld with Confidence!

This resource is more than just a handbook – it’s a practical tool for everyday work. For anyone looking to professionally process thermoplastic roofing membranes, this guide delivers clear answers, step-by-step instructions, and plenty of “aha!” moments.