Author: Chantal Manella, Marketing Specialist, Leister AG, Switzerland

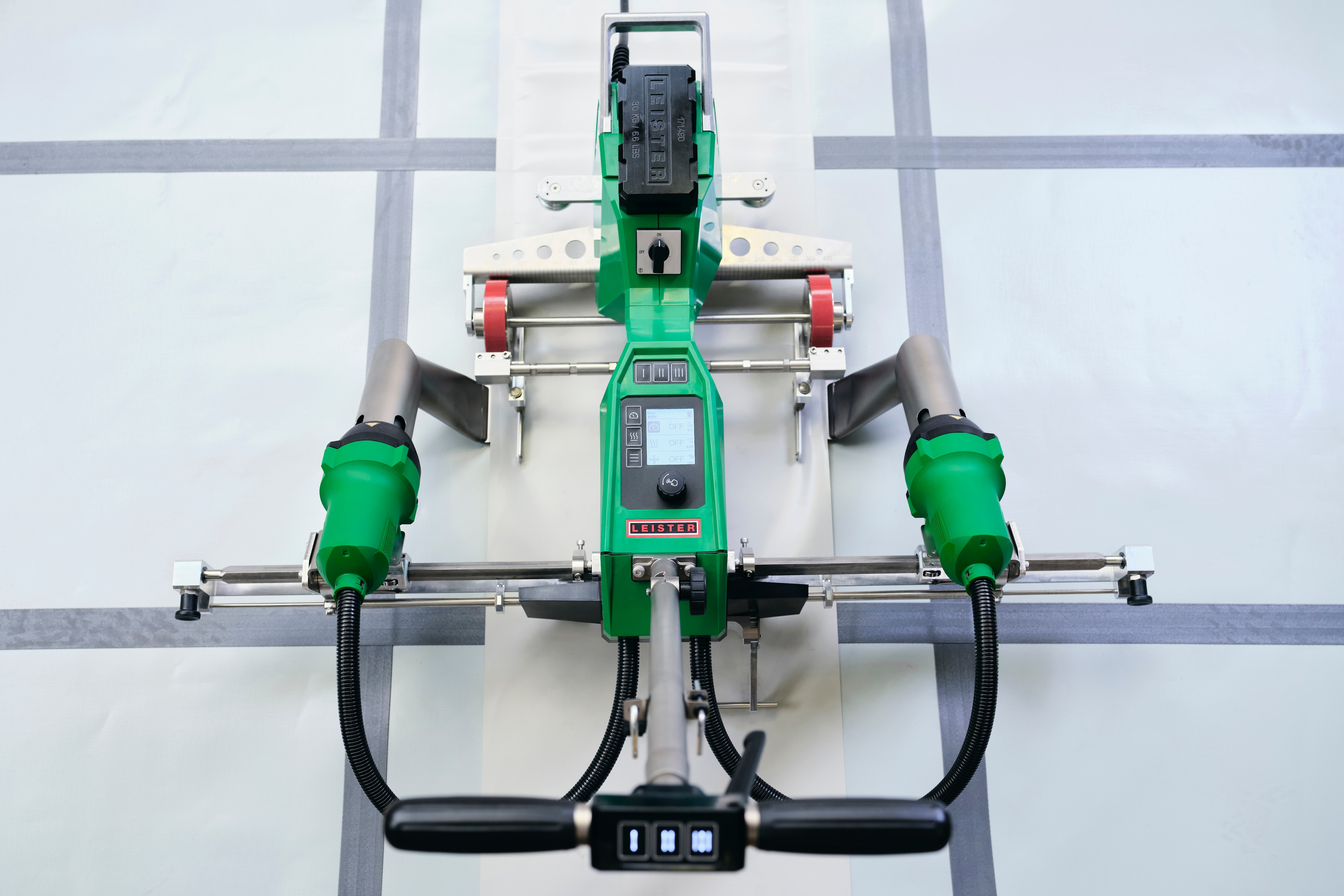

The new VARIANT replaces the predecessor models VARIANT T1, VARIANT T1 Tape, TAPEMAT and TAPEMAT SPRIEGEL. Wow – how does that work? Simply put, the new VARIANT welding machine from Leister has a modular design. This means it can be converted as required. You can use the device for bow, strip or overlap welding – all in one, so to speak. We call it revolutionary.

Super-Fast Welding

It can be time consuming to process all the reinforcement strips and bow seams welded on both sides of a truck tarpaulin. Not so with the VARIANT 706/708. This is because two-sided welding at a welding speed of up to 20 m/min reduces the welding time by 50 %. You can process different materials with welding widths between 20 mm and 50 mm. The distance between the two nozzles or weld seams can be individually adjusted from 80 to 400 mm.

Reinforce Tarpaulins with Tapes – Protection Against Vandalism

Truck tarpaulins can be cut open silently with a knife and the load stolen unnoticed, e. g. when the truck driver is taking a break. This can be prevented by welding truck tarpaulins with anti-vandalism tapes. The VARIANT 704/708 from Leister is the right choice. The investment is definitely worth it. And best of all: thanks to the double nozzle system of the VARIANT 708, you can now work even more efficiently.

Overlap Welding

The third discipline that our all-rounder masters perfectly: with the VARIANT 700, welding overlap seams on advertising banners, tarpaulins or truck tarpaulins made of PVC, PP or PE is a breeze.

Operation at the Touch of a Button

The intelligent button operation on the guide bar makes the lifting and welding process easier. This controls the automatic lifting of the material, the swiveling of the nozzle and the start of the welding process. And all while standing, to protect your health and ensure a safe welding process.

Plug-and-Play Wheels

The plug-and-play wheels enable effortless repositioning and easy transportation of the welding machine to different working environments.

The Best of the Five Models from the new VARIANT Series at a Glance: