The goal? Build a durable, sustainable vessel using only HDPE, a first-of-its-kind innovation in boatbuilding. To bring this vision to life, the team needed not only experience but the right equipment and support. That’s where Leister came in.

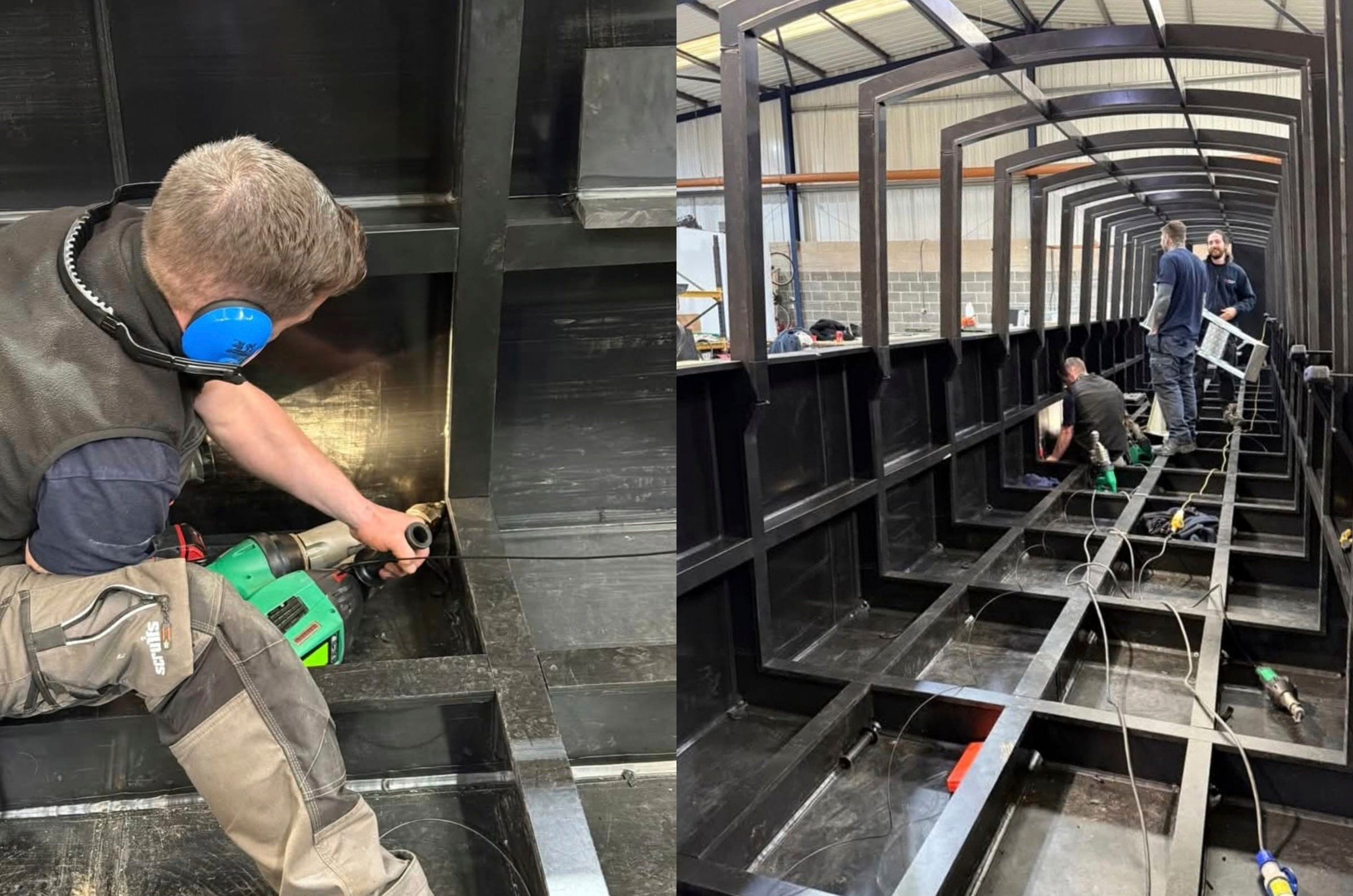

Welding Innovation into Every Inch

Formation Plastics had already been relying on Leister’s trusted tools such as the TRIAC ST, TRIAC AT, and WELDPLAST S4 for previous projects. But this build required even more power, flexibility, second and precision. With Leister’s support, they expanded their welding toolkit to include the WELDPLAST S2, FUSION 1, and FUSION 2.

Each tool brought unique strengths to the table:

- FUSION 1 handled tight and intricate areas.

- FUSION 2 ensured high-strength welds on larger seams.

- WELDPLAST S2 delivered consistent, heavy-duty extrusion performance.

Custom welding shoes were also used to adapt to different weld types and finishes—tailored precision from bow to stern.