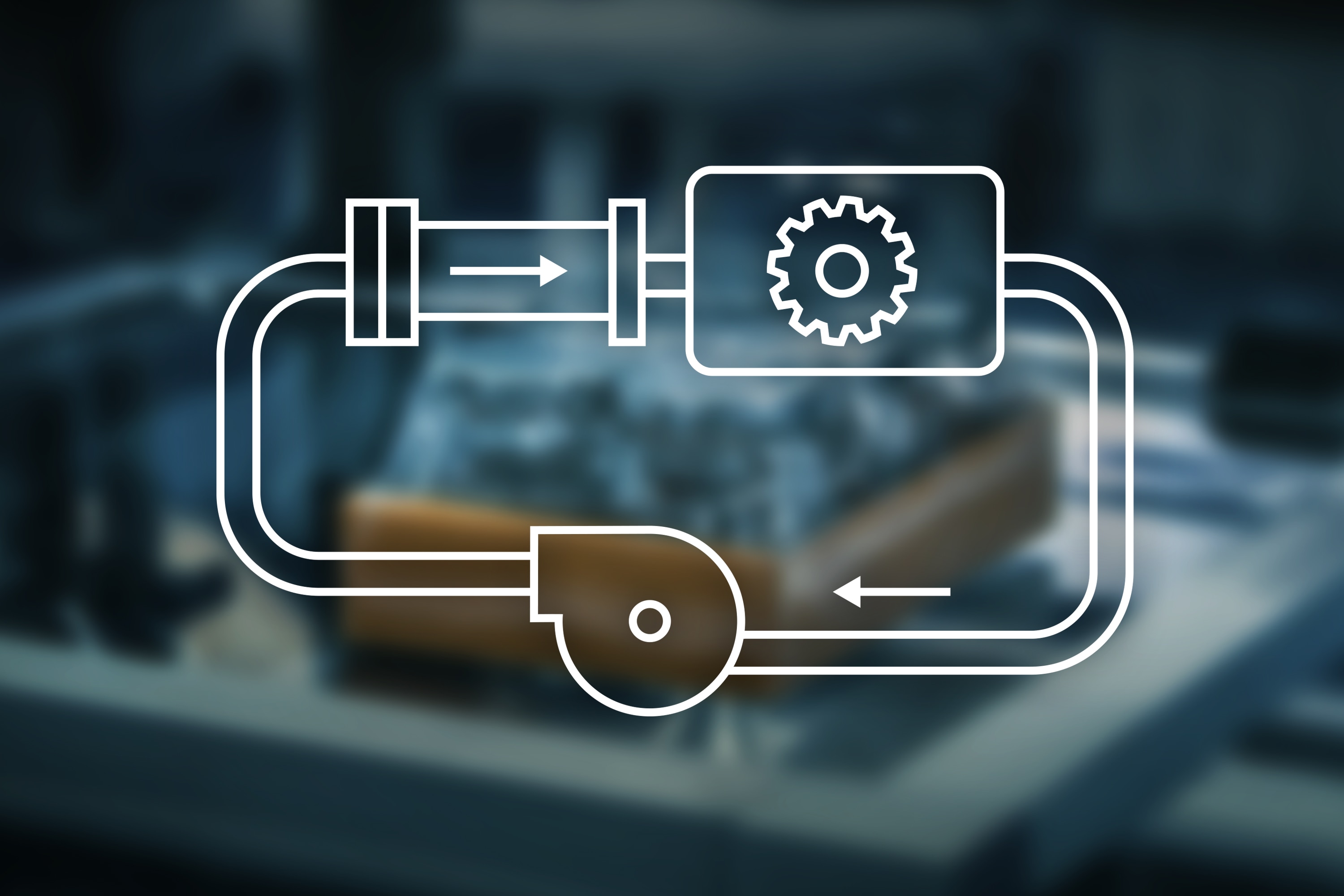

Hot air is used in many industrial processes worldwide. Those who use hot air recirculation operate their hot air systems in an energy-efficient, resource-saving, and process-safe manner. How does that work? In this whitepaper, two Leister experts give you the answers.