Hot-Air Technology

Hot air technology

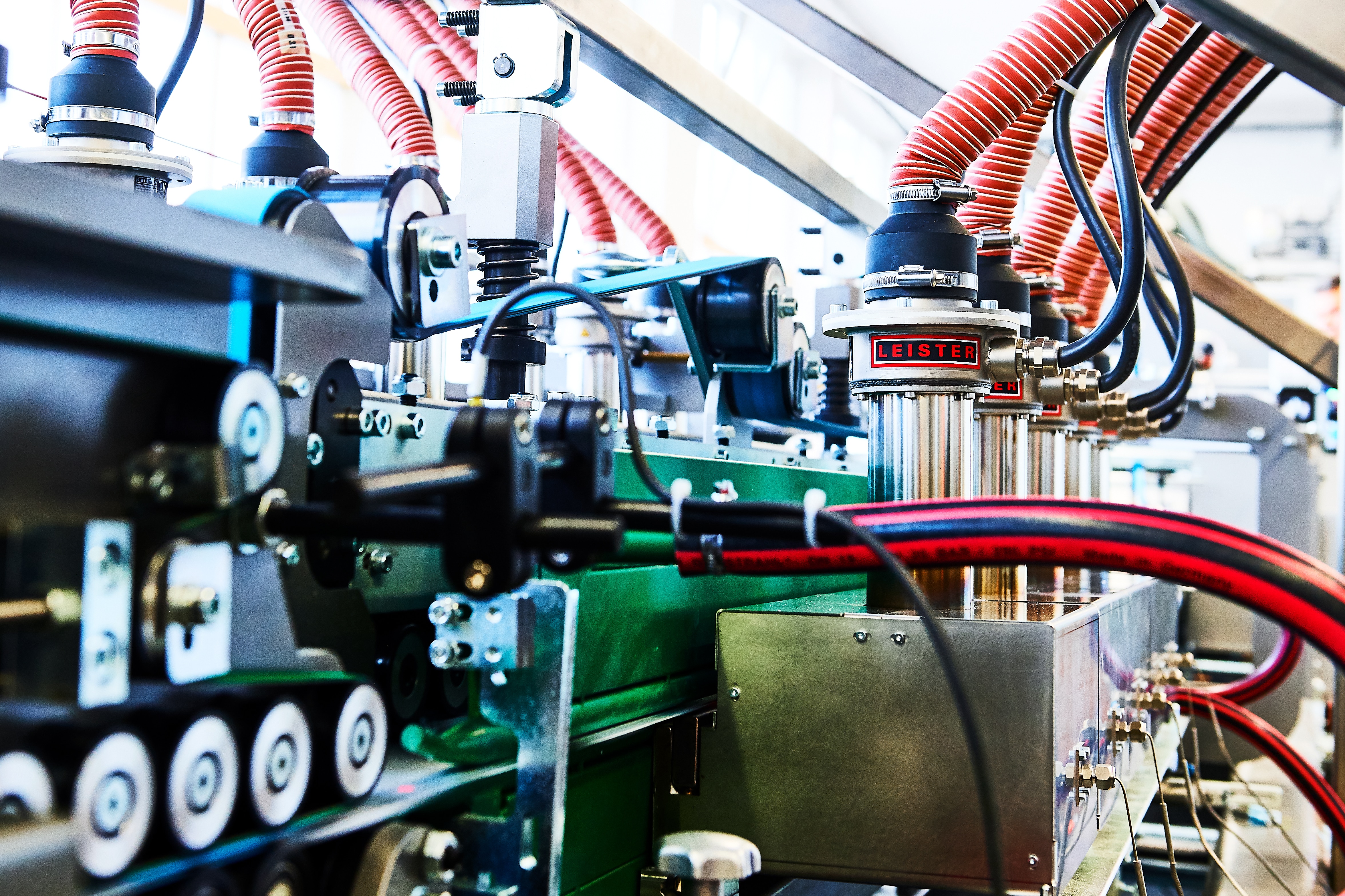

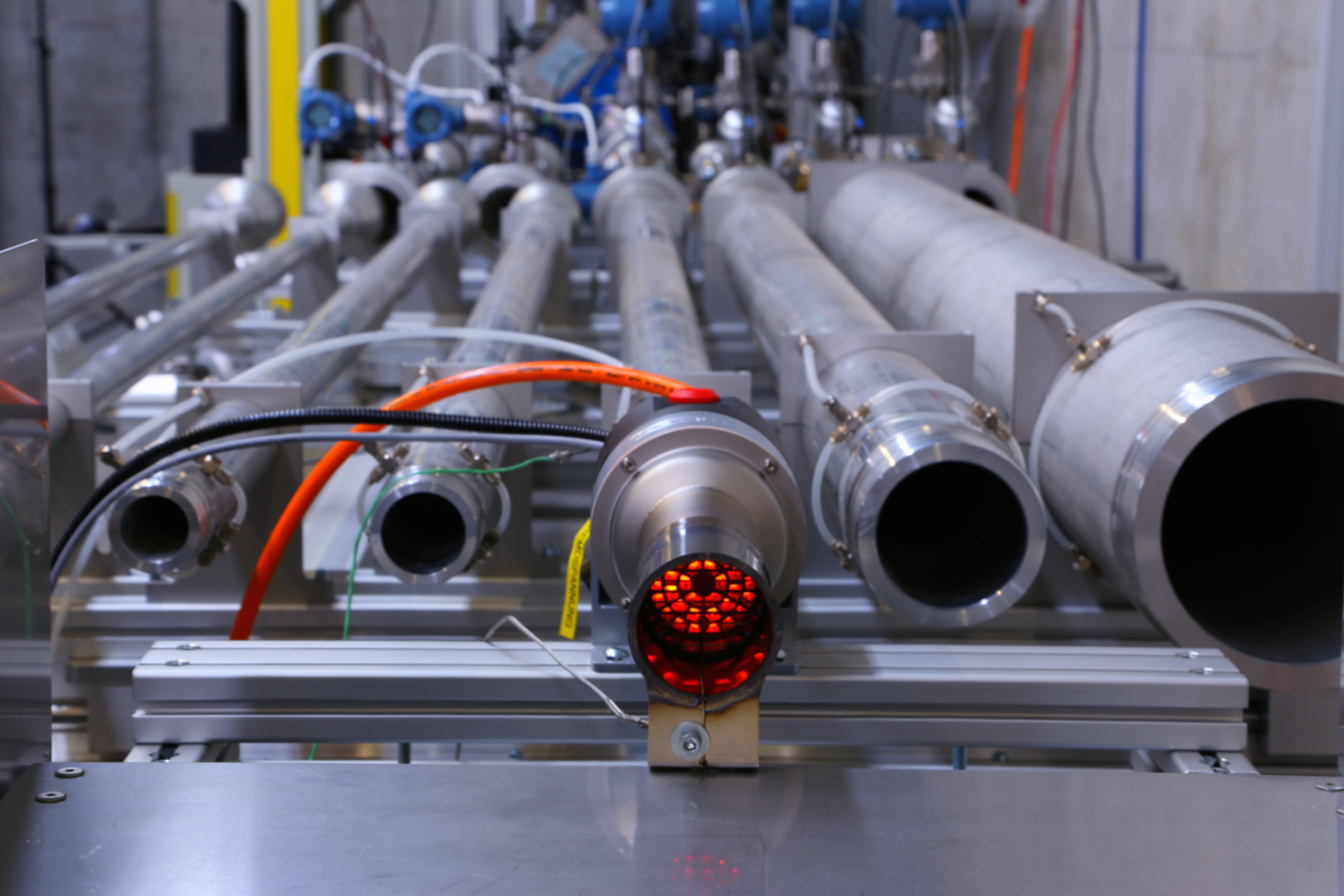

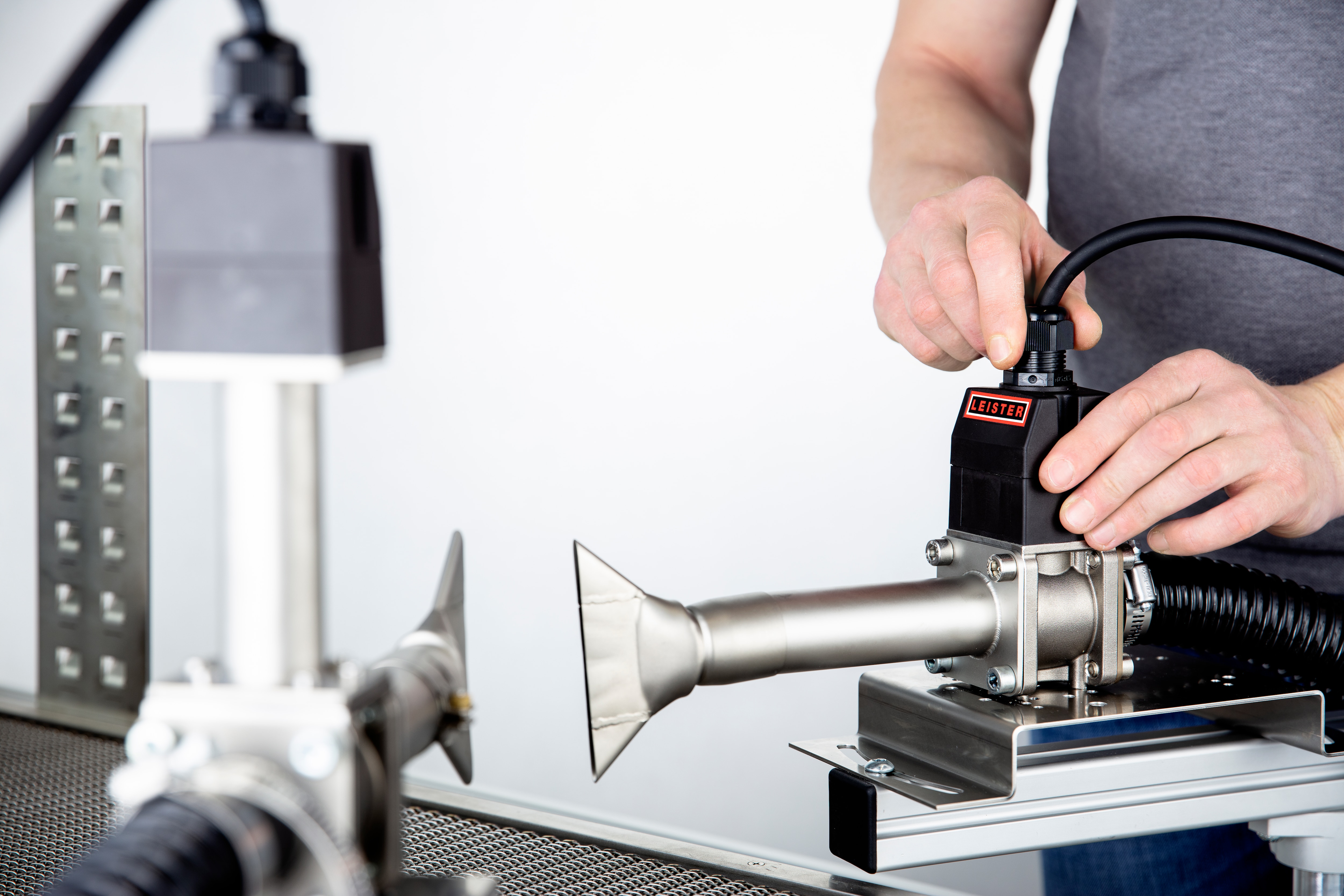

All over the world, blowers, hot air blowers, ignition blowers and air heaters from Leister are used in countless industrial production processes. Comprehensive know-how based on decades of experience in processing plastics makes Leister the ideal partner for individual and standardized solutions in all industries. Leister products for industrial hot air processes convince through precise controllability, simple integration into different production plants, exceptional performance, and high durability.

Do you need help by finding the right product? Our specialised sales team of Leister Japan will support you.

Applications

White paper

Industries

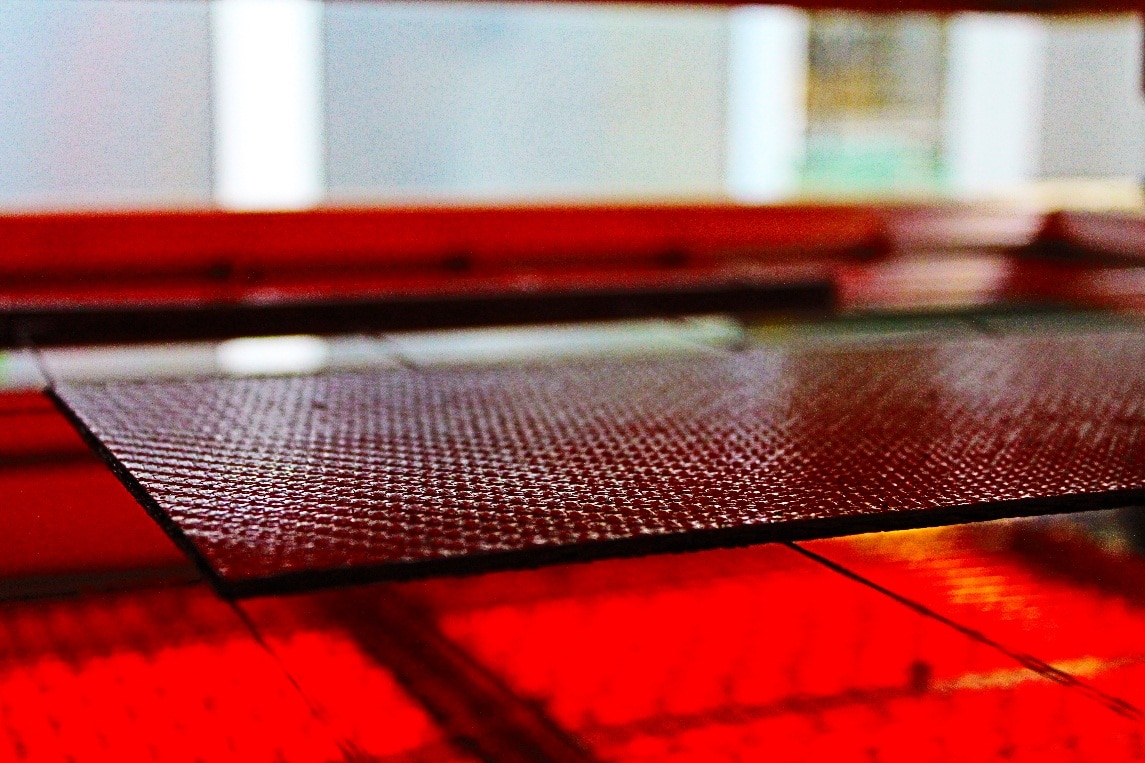

In the automotive industry, hot air is required to manufacture and process plastic and composite parts, e.g. for riveting components for door panels or for laminating dashboards. Leister hot air is also used in the production of batteries and motors for electric vehicles. The increased use of lightweight materials to achieve lower fuel consumption and lower CO2 emissions also increases the demands on new, efficient manufacturing methods. That is why hot air is often used to accelerate the process of hardening, laminating, drying and coating.

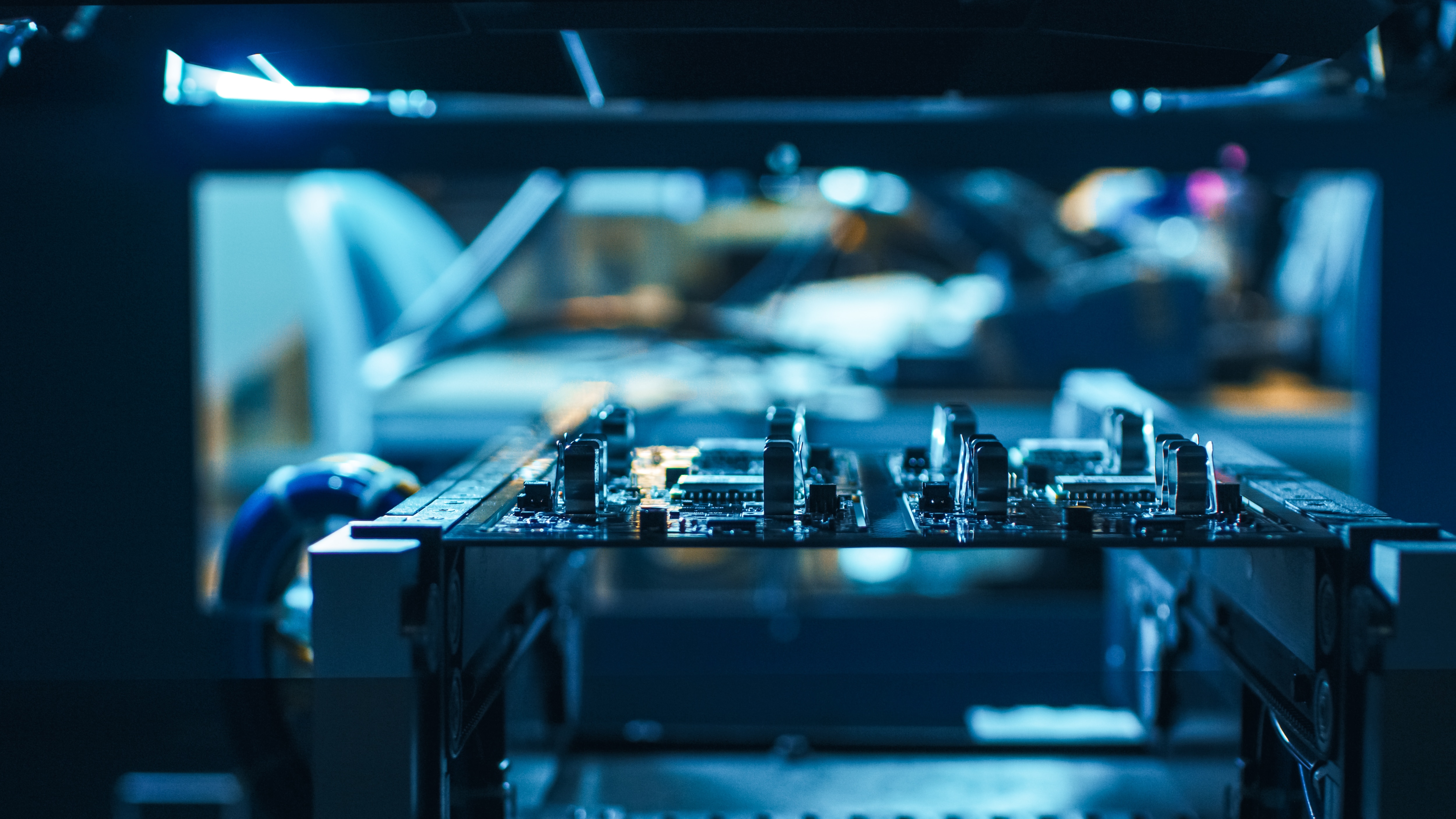

Leister air heaters and heat guns enable precise thermal process control, plus high availability for a large number of production processes within the electronics industry. In addition to soldering applications in electronics production, hot air is also used in wafer manufacturing. Thus, the sensitive silicone discs are blown evenly and gently with hot air from both sides during processing into photovoltaic modules.

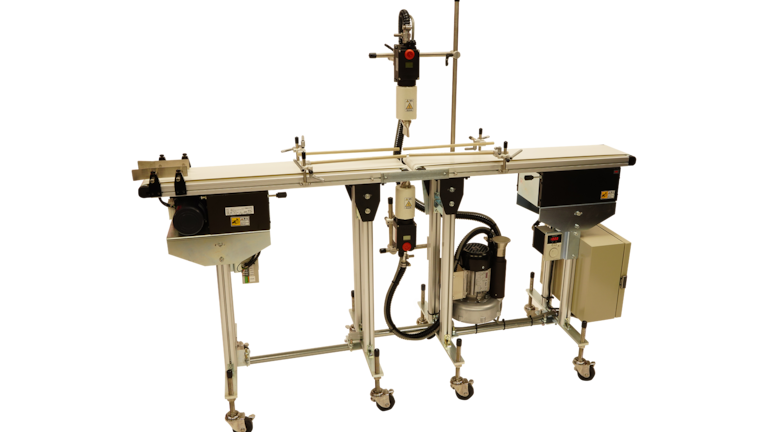

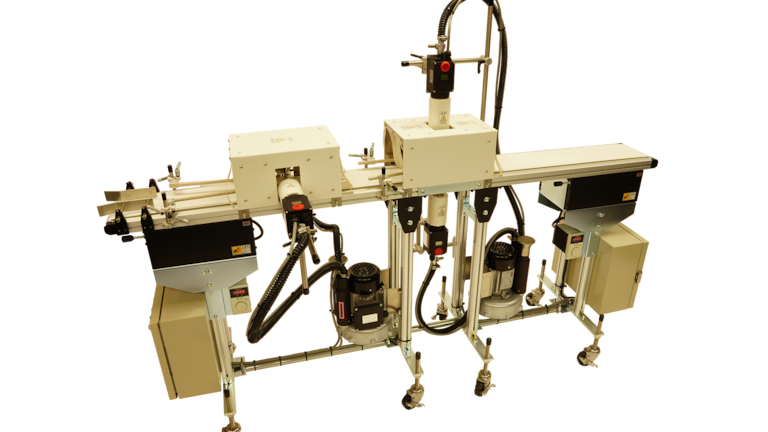

Different hot air processes are used in the cosmetics industry: The spectrum ranges from manufacturing and finishing to hygienic packaging. Leister hot air tools play an important role in every step of a process and have established themselves worldwide due to their precision, performance and durability.

In the food and beverage industry, hot air tools are used for sterilizing and cleaning machines and devices, as well as roasting coffee and drying fruit. Chocolates and other sweets are enhanced by the use of hot air, thanks to their high level of controllability and precise temperature regulation. Leister air heaters enable safe process control for optimum protection of food.

Thermal applications and processes are often used in high-quality machines and production systems for the production of technical components and consumer goods. Controllability of Leister air heaters and heat guns offers a handful of advantages in mechanical engineering. Additionally, Leister impresses with its unrivalled global network of service centers. This ensures that spare parts can be supplied to even the most remote corners of the world. Leister is a reliable hot-air partner for mechanical engineers around the globe.

In the pharmaceutical industry, a great deal of importance is placed on reliability and cleanliness. Safe process control depends on precise controllability. Leister hot air tools can even meet these stringent requirements. They are used for forming and sealing blister packs and for drying and smoothing pills or tablets.

In paper production, the drying process is often accelerated with hot air. When the paper is subsequently printed, it is important that the ink dries quickly to avoid staining. By using hot air, printed paper sheets and paper rolls dry faster and can thus be processed efficiently.

Another common application of hot air in paper processing is the lamination of paper and board with plastic film. Wallpapers are also laminated to enhance them or make them washable.

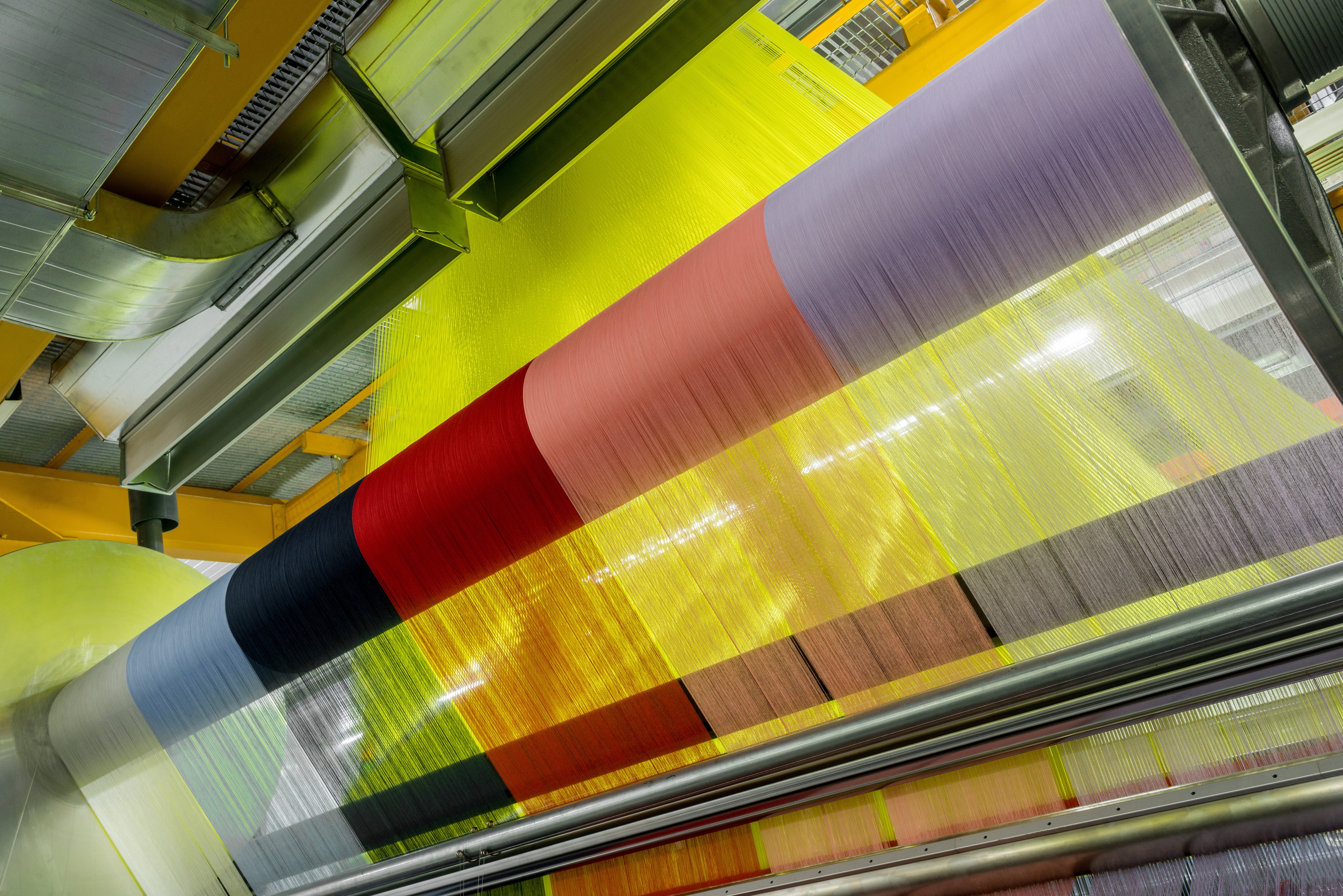

Manufacturing tissues, mixtures, netting, fleece materials and felt requires hot air for drying after dying or washing, as well as the coating of functional textiles. Polypropylene and polyester tissues require hot air in a fully automated, fast-paced systems, where the power density of the Leister air heater and their high maximum temperature come into effect to shorten the production time.

In order to package consumer goods, cling films and packaging films made of polymers (for example PET, PE-HD and PE-LD) are frequently sealed with heat guns from Leister. Plastic containers are also formed and sealed with hot air. In the cosmetics industry, hot air is used for the production of tubes and composite cartons. In addition, goods and packaging can be dried with Leister hot air and plastic shrink tubes/sleeves, can be shrunk or shrunk on.